Steam sequence

Page 122

Page 123

If you've noticed an error in this article please click here to report it so we can fix it.

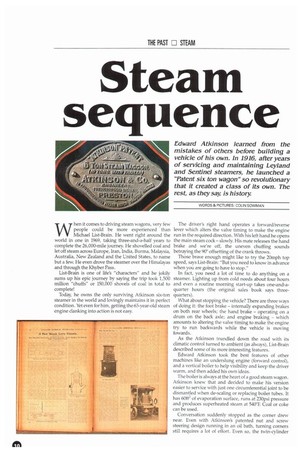

Edward Atkinson learned from the mistakes of others before building a vehicle of his own. in 1916, after years of servicing and maintaining Leyland and Sentinel steamers, he launched a "Patent six ton wagon" so revolutionary that it created a class of its own. The rest, as they say, is history

WORDS & PICTURES: COLIN SOWMAN

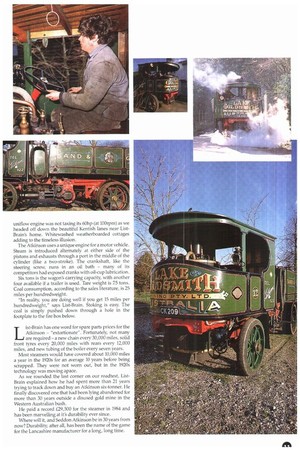

When it comes to driving steam wagons, very few people could be more experienced than Michael List-Brain. He went right around the world in one in 1969, taking three-and-a-half years to complete the 26,000-mile journey. He shovelled coal and let off steam across Europe, Iran, India, Burma, Malaysia, Australia, New Zealand and the United States, to name but a few. He even drove the steamer over the Himalayas and through the Khyber Pass.

List-Brain is one of life's "characters" and he jokily sums up his epic journey by saying the trip took 1,500 million "chuffs" or 150,000 shovels of coal in total to complete!

Today, he owns the only surviving Atkinson six-ton steamer in the world and lovingly maintains it in perfect condition. Yet even for him, getting the 65-year-old steam engine clanking into action is not easy. The driver's right hand operates a forward/reverse lever which alters the valve timing to make the engine run in the required direction. With his left hand he opens the main steam cock slowly. His mate releases the hand brake and we're off, the uneven chuffing sounds betraying the 90° offsetting of the crank throws.

Those brave enough might like to try the 20mph top speed, says List-Brain: "But you need to know in advance when you are going to have to stop."

In fact, you need a lot of time to do anything on a steamer. Lighting up from cold needs about four hours and even a routine morning start-up takes one-and-aquarter hours (the original sales book says threequarters).

What about stopping the vehicle? There are three ways of doing it: the foot brake internally expanding brakes on both rear wheels; the hand brake operating on a drum on the back axle; and engine braking which amounts to altering the valve timing to make the engine try to run backwards while the vehicle is moving towards.

As the Atkinson trundled down the road with its climatic control turned to ambient (as always), List-Brain described some of its more interesting features.

Edward Atkinson took the best features of other machines like an underslung engine (forward control), and a vertical boiler to help visibility and keep the driver warm, and then added his own ideas.

The boiler is always at the heart of a good steam wagon. Atkinson knew that and decided to make his version easier to service with just one circumferential joint to be dismantled when de-scaling or replacing boiler tubes. It has 60ft2 of evaporation surface, runs at 230psi pressure and produces superheated steam at 540°F. Coal or coke can be used.

Conversation suddenly stopped as the corner drew near. Even with Atkinson's patented nut and screw steering design running in an oil bath, turning corners still requires a lot of effort. Even so, the twin-cylinder uniflow engine was not taxing its 60hp (at 100rpm) as we headed off down the beautiful Kentish lanes near ListBrain's home. Whitewashed weatherboarded cottages adding to the timeless illusion.

The Atkinson uses a unique engine for a motor vehicle. Steam is introduced alternately at either side of the pistons and exhausts through a port in the middle of the cylinder (like a two-stroke). The crankshaft, like the steering screw, runs in an oil bath many of its competitors had exposed cranks with oil-cup lubrication.

Six tons is the wagon's carrying capacity with another four available if a trailer is used. Tare weight is 7.5 tons. Coal consumption, according to the sales literature, is 25 miles per hundredweight.

"In reality, you are doing well if you get 15 miles per hundredweight," says List-Brain. Stoking is easy. The coal is simply pushed down through a hole in the footplate to the fire box below.

List-Brain has one word for spare parts prices for the Atkinson "extortionate". Fortunately, not many are required a new chain every 30,000 miles, solid front tyres every 20,000 miles with rears every 12,000 miles, and new tubing of the boiler every seven years.

Most steamers would have covered about 10,000 miles a year in the 1920s for an average 10 years before being scrapped. They were not worn out, but in the 1920s technology was moving apace.

As we rounded the last corner on our roadtest, ListBrain explained how he had spent more than 21 years trying to track down and buy an Atkinson six-tonner. He finally discovered one that had been lying abandoned for more than 30 years outside a disused gold mine in the Western Australian bush.

He paid a record £29,500 for the steamer in 1984 and has been marvelling at its durability ever since.

Where will it, and Seddon Atkinson be in 30 years from now? Durability after all, has been the name of the game for the Lancashire manufacturer for a long, long time.