'Bespoke' Tippers Prove Their Worth

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

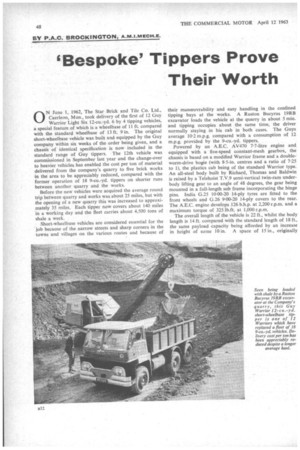

ON June 1, 1962, The Star Brick and Tile Co. Ltd., Caerleon, Mon., took delivery of the first of 12 Guy Warrior Light Six 12-cu.-yd. 6 by 4 tipping vehicles, a special feature of which is a wheelbase of 11 ft. compared with the standard wheelbase of 13 ft. 9 in. The original short-wheelbase vehicle was built and equipped by the Guy company within six weeks of the order being given, and a chassis of identical specification is now included in the standard range of Guy tippers. The 12th vehicle was commissioned in September last year and the change-over to heavier vehicles has enabled the cost per ton of material delivered from the company's quarry to five brick works in the area to be appreciably reduced, compared with the former operation of 18 9-cu.-yd. tippers on shorter runs between another quarry and the works. Before the new vehicles were acquired the average round trip between quarry and works was about 25 miles, but with the opening of a new quarry this was increased to approximately 35 miles. Each tipper now covers about 140 miles in a working day and the fleet carries about 4,500 tons of shale a week. Short-wheelbase vehicles are considered essential for the ' job because of the narrow streets and sharp corners in the towns and villages on the various routes and because of their rnanceuvrability and easy handling in the confined tipping bays at the works. A Ruston Bucyrus 19RB excavator loads the vehicle at the quarry in about 5 min. and tipping occupies about the same time, the driver normally staying in his cab in both cases. The Guys average 10-2 m.p.g. compared with a consumption of 12 m.p.g. provided by the 9-cu.-yd. tippers. Powered by an A.E.C. AV470 7.7-litre engine and equipped with a five-speed constant-mesh gearbox, the chassis is based on a modified Warrior frame and a doubleworm-drive bogie (with 8-5-in. centres and a ratio of 7-25 to 1), the plastics cab being of the standard Warrior type. An all-steel body built by Richard, Thomas and Baldwin is raised by a Telehoist T.V.9 semi-vertical twin-ram underbody lifting gear to an angle of 48 degrees, the gear being mounted in a full-length sub frame incorporating the hinge pins. India G.25 10-00-20 14-ply tyres are fitted to the front wheels and 0.26 9-00-20 14-ply covers to the rear. The A.E.C. engine develops 126 b.h.p. at 2,200 r.p.m. and a maximum torque of 325 Ibit. at 1,000 r.p.m..

The overall length of the vehicle is 22 ft., whilst the body length is 14 ft. compared with the standard length of 18 ft., the same payload capacity being afforded by an increase in height of some 10 in. A space of 15 in., originally provided between the body and cab to increase rear-wheel loading, has been reduced to a nominal amount. Unladen weight of the vehicle is 7 tons 8 cwt., of which the body accounts for 1 ton 15 cwt.

Modifications to the chassis include mounting the engine at an angle appropriate to the shortened wheelbase and the use of a Girling dual-circuit air-over-hydraulic braking system. It is notable that ithas not been necessary to reline the brakes of a vehicle that has covered over 18,000 miles (the maximum so far recorded) which represents an above-average life of the friction material, the steep gradients in the area being particularly severe on the linings.

Guy Invincible tractive units with 16-ton semi-trailers will later be employed in place of a fleet of Commer,

B.M.C. and Thames articulated outfits of 12-14 ton capacity for the delivery of bricks from the area to all parts of the country by the parent company, National Star Brick and Tile Holdings Ltd. Trailers will be fitted with Hub o equipment of Dutch origin which will enable one man to load or unload a vehicle in 30 min., whereas normal loading takes four men about 1 hr. Features of the equipment include a multi-fork lifting frame and a hoist with a traversing boom, which is electrically driven and remotely controlled by the operative with the aid of a switch unit on a wandering lead. According to a representative of the brick company the equipment could also be used for other types of load.