THIR Fil' TIPS

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

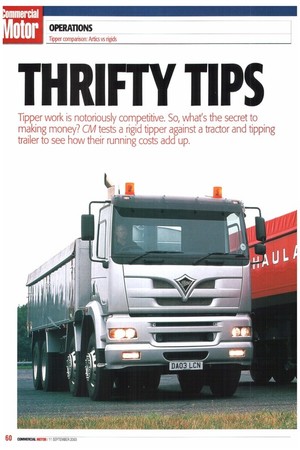

Tipper work is notoriously competitive. So, what's the secret to making money? CM tests a rigid tipper against a tractor and tipping trailer to see how their running costs add up.

Repetitive short-haul trips are standard fare for tipper operators running on four axles. Invariably factors such as small sites, restricted accesses and conservative management traditions have meant the 8x4 tipper is the most cost-effective truck an operator can use.

But, with long-term contracts and the introduction of major projects like the toll road at Birmingham, tipper operators have found a more cost-effective way to run their businesses, using tipper trailers at 44 tonnes. This offers more payload and fewer trips.

CM has found a definite difference in fuel consumption between 40 and 44 tonnes — we can only imagine how much the mpg gap will widen. between 32 and 44 tonnes. It should be noted at this point though that the fuel figures that follow are notable for the discrepancy between them only and not as a definitive guide as to what an individual make or model would achieve.

The most obvious change is the 12 tonnes higher GVW offering around 41% extra payload (about nine tonnes, taking into account the weight of the tractor and trailer) but on the downside there is more rolling resistance with an extra couple of axles.

Financially there is little to choose between them: VED rates are in the same band for running at maximum weight according to the axle spread. increasing driver's pay to Class One, and looking after two bits of kit rather than one. The outlay for a tractor and tipping trailer as opposed to just a chassis cab and body, and the delays in loading and unloading for a bigger load space are extra expenses.

What we did

CM took the Foden rigid and tractor around a 95km route, starting and finishing at the BP Station on the AS near Hinckley, to check the fuel consumption.We travelled along the AS towards Cannock before turning right onto the A444, and then over the M42 towards Burton-on-Trent. We turned right at Stapen hill. and right again onto the A511 out of Burton back to the A42; here we headed south joining the M42 before turning off onto the AS and completing a figure of eight back to Hinckley.

We ran the test with both vehicles rated at approximately 10hp per tonne to keep them as evenlymatched as possible.

We measured the load spaces and weighed them empty, to give capacity and overall payload figures. We took into account the number of trips it took for both vehicles to deliver to the same payload, and the level of productivity produced by each vehicle. Pi*