From the

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

fri LIX a I C u

by Graham Montgomeri Developments in turbocharging continue apace but there are many problems that sti remain. Neil Watson of the London Imperia College of Science and Technology is in th( forefront of the research drive, and in a collection of papers just published, his wor on resonant intake and variable geometry methods of achieving high torque at low speeds for a V8 diesel engine makes • very interesting reading

IT CANNOT have escaped the attention of those involved in the commercial vehicle field, in whatever capacity, that turbocharged diesel engines have all but taken over from their naturally aspirated forebears.

The Institution of Mechanical Engineers has recently published a very informative (but, at £42, expensive) book on the subject, it being the collected papers of the conference held in London in April this year.

Entitled Turbocharging and Turbochargers, the book describes a number of recent avenues of exploration in the field of forced induction, including work by Neil Watson of Imperial College of Science and Technology, London on resonant intake and variable geometry systems.

A fundamental method of improving the turbocharger boost at low engine speed is the variable geometry turbine since this alters the air-flow characteristics to suit the application. A few companies have been experimenting with variable geometry systems for some time now, but to date no such system is in production. The benefits can be great but the high cost of the complexity has weighed against it.

Another technique is to use a resonant intake system whereby the inlet manifold pressure can be increased by pressure wave action at the point of inlet valve closure.

Mr Watson's chapter compares and contrasts both the resonant intake and variable geometry methods of achieving high torque at low speeds for a V8 diesel engine using a Perkins TV8.510 engine.

Mr Watson claims that the resonant intake system could be adapted to a V8 engine to increase low speed torque over quite a large speed range. It could also be used for on-line four as being effectively half the V8 configuration. The main advantage of such a system would be its comparatively low manufacturing cost but a further advantage would be its reliability as it does not involve any moving parts.

There is, however, one major disadvantage according to Mr Watson and that is the physical volume of the system. However the V8 engine is less sensitive in this respect as it was possible to install the resonant volumes and the pipe lengths in the V while still leaving sufficient room for the fuel pump.

Tests results showed that at the resonant speed (1,400rpm) a torque increase of 14 per cent was measured, decreasing to zero at 1,000 and 1,800rpm. Th torque back-up increased from 26 per cent at 71 per cent rated speed to 34 per cent at 61 per cent speed.

The variable geometry turbocharging system increase the torque at low engine speed by a much greater effort. At 1,600rpm the increase was found to be 23 per cent and Mr Watson suggested that this could rise to 35 per cent with a turbine re-design.

Even with what Mr Watson described as the "non-optimur

adaption" of a standard production turbocharger, the

torque back-up increased to 47 per cent at 60 per cent of laximum engine speed. Again, Mr Watson claimed le an improvement in torque ack-up to 70 per cent should e possible with an optimised ariable geometry system. According to Mr Watson the bvious disadvantages of ariable geometry turbochargers re higher cost and potential nreliability and he stressed that rrther development would be )quired to improve both fficiency and durability. Although resonant intake (stems and variable geometry irbochargers are aimed at the sme goal, they are quite ifferent approaches to the roblem. While the choice etween them depends upon le performance improvement quired, Mr Watson thought it erfectly feasible for both (stems to be used together. It is ssential, however, for such (stems to be compared with her methods of improving the Irque at low speeds — with the Dvious one being a irbocharger re-match.

Mr Watsons suggests that arhaps the most significant ternative is the Mack approach matching for high boost over a limited speed range and reducing the fuel delivery at high engine speed to avoid excessive boost. Although this results in some very impressive torque curves, the penalty is low-rated power output for the engine capacity and a high specific fuel consumption at high speed.

Mr Watson suggests that variable geometry turbochargers are most likely to be used in applications where high specific power and good torque back-up are required and they could be used in conjunction with a resonantintake system. The latter system alone would be favoured for engines at modest ratings requiring torque back-up, particularly in applications where long-term durability is most important.

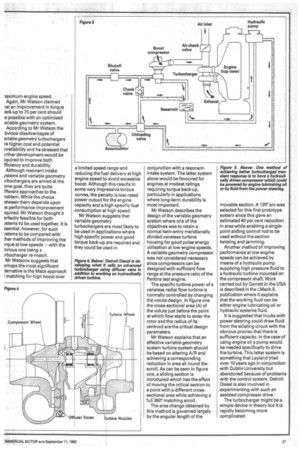

Mr Watson describes the design of the variable geometry system where one of the objectives was to retain a normal twin-entry meridianally divided vaneless turbine housing for good pulse energy utilisation at low engine speeds. A variable geometry compressor was not considered necessary since compressors can be designed with sufficient flow range at the pressure ratio of the Perkins test engine.

The specific turbine power of a vaneless radial flow turbine is normally controlled by changing the volute design. In figure one the cross-sectional area (A) of the volute just before the point at which flow starts to enter the rotor and the radius of its centroid are the critical design parameters.

Mr Watson explains that an effective variable geometry system turbine system should be based on altering A/R and achieving a corresponding reduction in area all round the scroll. As can be seen in figure one, a sliding section is introduced which has the effect of moving the critical section to a point with a different crosssectional area while achieving a full 360° matching scroll.

The area change obtained by this method is governed largely by the angular length of the

movable section. A 120° arc was selected for this first prototype system since this gave an estimated 40 per cent reduction in area while enabling a singlepoint sliding control rod to be used without the section

twisting and jamming.

Another method of improving performance at low engine speeds can be achieved by means of a hydraulic pump supplying high pressure fluid to a hydraulic turbine mounted on the compressor shaft. Work carried out by Garrett in the USA is described in the I.Mech.E. publication where it explains that the working fluid can be either engine lubricating oil or hydraulic systems fluid.

It is suggested that trucks with power steering could draw fluid from the existing circuit with the obvious proviso that there is sufficient capacity. In the-case of using engine oil a pump would be needed specifically to drive the turbine. This latter system is something that Leyland tried over 10 years ago in conjunction with Dublin University but abandoned because of problems with the control system. Detroit Diesel is also involved in experimenting with such an assisted compresser drive.

The turbocharger might be a simple device in theory but it is rapidly becoming more complicated.