Dennis first with Perkins turbo

Page 131

Page 132

If you've noticed an error in this article please click here to report it so we can fix it.

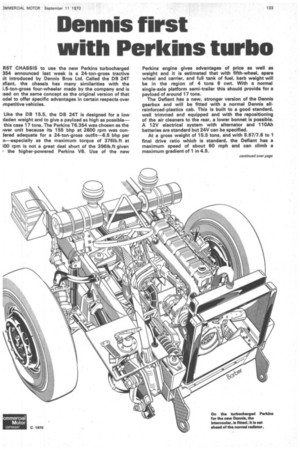

AST CHASSIS to use the new Perkins turbocharged 354 announced last week is a 24-ton-gross tractive it introduced by Dennis Bros Ltd. Called the DB 24T afiant, the chassis has many similarities with the i.5-ton-gross four-wheeler made by the company and is ised on the same concept as the original version of that odel to offer specific advantages in certain respects over rmpetitive vehicles.

Like the DB 15.5, the DB 24T is designed for a low 'laden weight and to give a payload as high as possible— this case 17 tons. The Perkins T6.354 was chosen as the iwer unit because its 155 bhp at 2600 rpm was conlered adequate for a 24-ton-gross outfit-6.5 bhp per n—especially as the maximum torque of 3761b.ft at 100 rpm is not a great deal short of the 3961b.ft given the higher-powered Perkins V8. Use of the new Perkins engine gives advantages of price as well as weight and it is estimated that with fifth-wheel, spare wheel and carrier, and full tank of fuel, kerb weight will be in the region of 4 tons 6 cwt. With a normal single-axle platform semi-trailer this should provide for a payload of around 17 tons.

The Defiant has a new, stronger version of the Dennis gearbox and will be fitted with a normal Dennis allreinforced-plastics cab. This is built to a good standard, well trimmed and equipped and with the repositioning of the air cleaners to the rear, a lower bonnet is possible. A 12V electrical system with alternator and 110Ah batteries are standard but 24V can be specified.

At a gross weight of 15.5 tons, and with 5.57/7.6 to 1 final drive ratio which is standard, the Defiant has a maximum speed of about 60 mph and can climb a maximum gradient of 1 in 4.5.

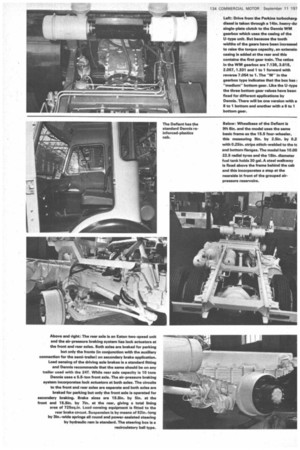

Above and right; The rear axle is an Eaton two-speed unit and the air-pressure braking system has lock actuators at the front and rear axles. Both axles are braked for parking but only the fronts in conjunction with the auxiliary connection for the semi-trailer) on secondary brake application. Load sensing of the driving axle brakes is a standard fitting and Dennis recommends that the same should be on any trailer used with the 24T. While rear axle capacity is 10 tons Dennis uses a 5.5-ton front axle. The air-pressure braking system incorporates lock actuators at both axles. The circuits to the front and rear axles are separate and both axles are braked for parking but only the front axle is operated for secondary braking. Brake sizes are 15.5in. by Sin, at the front and 15.5in. by 7in. at the rear, giving a total lining area of 725sq.in. Load-sensing equipment is fitted to the rear brake circuit. Suspension is by means of 521n.-long by 31n.-wide springs all round and power-assisted steering by hydraulic ram ia standard. The steering box is a recirculatory ball type.