Foden changes include higher weight models

Page 126

Page 127

Page 128

If you've noticed an error in this article please click here to report it so we can fix it.

A 38-TON TWIN-STEER AND A 30-TON 8 x 4

THE exhibits Fodens Ltd will be featuring at the Commercial Motor Show will illustrate changes made recently to standard Foden models to reduce the number of variations in production. A major exercise has been undertaken by the company to revise the model programme and base chassis availability on what customers are actually ordering. The new model list has been devised to satisfy 95 per cent of customers and in many respects this has been done by making a higher-standard option the regular fitting and eliminating the lower-standard item. Overall, the customer should benefit as the changes will allow Fodens to streamline production and it is said that improved specifications will be incorporated without cost penalty.

One way in which this has been done is by making improved instrumentation in the cab and a Chapman suspension seat standard, and by reducing cab options to four variants. These are the S60 all-steel two-man cab with reverse sloping screen, the S50 which is the half-cab version of this one, the S70 reinforced-plastics version of the S60 and the S39 older design of reinforced-plastics cab with curved panelling. In making the model changes Fodens has looked at possible future legislation and designed accordingly; one way in which this has an important effect is where engines have been dropped from models if they did not provide for 6 bhp per ton power-to-weight to be attained.

Two new models will be shown on the Fodens stand at Earls Court and a third exhibit will be seen in public for the first time. The new chassis are an eight-wheel tipper designed for operation at up to 30 tons gross which is a figure being talked of for the future, but limited by its 23ft outer axle spread to 26 tons at present. The second is a six-wheel twin-steer tractive unit for operation at 38 tons gross in the future and fitted with a Gardner 8LXB 240 bhp engine. The older model which is being exhibited for the first time is a 6 x 4 tractive unit designed for 44-ton-gross operation and this is fitted with a turbocharged Cummins diesel developing 270 bhp.

Different cabs are mounted on each chassis, the S50 half-cab on the eight-wheeler, the S60 steel cab with forward-sloping screen on the 44-ton-gross tractive unit and the S70 reinforced-plastics version of the S60 on the twin-steer model. Common features of these three modt which illustrate the company's rationali2 tion programme referred to, o air-assisted clutches with sintered-irt driven plates, 12-speed overdrive gearbox and spring /hydraulic cab rear rnountini the back of each cab is supported throu coil springs surrounding an hydrau damper while there are conical rubber /stt mountings at the front. The gearbox used the Foden 5DP which is the latest version the Foden 12-speed unit and has a 700 lb torque capacity as against 600 lb ft for t older 6DP which is now discontinued, ' get to the higher figure, bigger bearings a wider gears are employed and there is nt constant mesh engagement for all ratios.

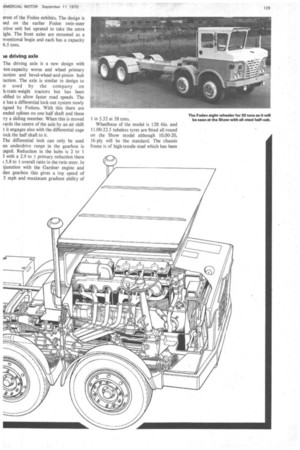

Because it has the Gardner 8LXB engi which produces 240 bhp at 1850 rpm, t twin-steer tractive unit for 38 tons grc operation will no doubt create the int erest of the Foden exhibits. The design is sed on the earlier Foden twin-steer .ctive unit but uprated to take the extra ight. The front axles are mounted as a nventional bogie and each has a capacity 6.5 tons.

to driving axle The driving axle is a new design with -ton-capacity worm and wheel primary luction and bevel-wheel-and-pinion hub luction. The axle is similar in design to it used by the company on ,h-train-weight tractors but has been ■ dified to allow faster road speeds. The e has a differential lock-out system newly kgned by Fodens. With this there are ended splines on one half shaft and these Ty a sliding member. When this is moved yards the centre of the axle by an air shift t it engages also with the differential cage lock the half shaft to it.

Ile differential lock can only be used en underdrive range in the gearbox is taged. Reduction in the hubs is 2 to 1 1 with a 2.9 to 1 primary reduction there t 5.8 to I overall ratio in the twin steer. In ijunction with the Gardner engine and den gearbox this gives a top speed of 5 mph and maximum gradient ability of 1 in 5.32 at 38 tons.

Wheelbase of the model is 12ft 6in. and 11.00-22.5 tubeless tyres are fitted all round on the Show model although 10.00-20, 16-ply will be the standard. The chassis frame is of high-tensile steel which has been used for some time by Fodens and in this application the dimensions are 12in. by 4in. by 0.3125in.

Brake sizes are 16.5in. by 7in. all round, and operation is by dual-diaphragm lock actuators at each wheel. The secondary system is applied to the foremost and driving axle with parking on all three to ensure that parking will be possible at 38 tons on a I in 6.25 gradient even with a relatively low adhesion road surface.

Heavier axles The 30-ton-gross eight-wheeler is based on the Foden 26-ton design but with heavier axles, springs, tyres, frame and steering. The chassis has a Gardner 6LXB 180 bhp diesel which with the Foden I2-speed box and 5.75 to 1 axle ratio gives a maximum speed of 49 mph and maximum gradient ability of 1 in 3.5 at the 30 ton figure. Frame size is 12in. by 4in. by 0.375in. and while the existing rear bogie is employed—designed for a total of 20 tons at the ground—and four-spring suspension layout, the front axles have been completely re-designed to allow 6.5 tons at the ground (plated front axle weights are 6 tons through tyres and springs fitted).

The highest weight eight-wheeler made by Fodens up to now has had 5.25-ton front axles and to get the extra 1.25-ton capacity the diameters of the stubs have been increased from 2.25in. to 3in. with the swivel pin increased to I.5in. at the top and 1.75in. at the bottom from 1.25in. and 1.5in. respectively. The lower surface of the kingpin is now chromium plated and the overall width of the axle has been increased to the maximum possible dimension which improves the turning angle on the wheels. Front brake sizes are now I6.5in. diameter by 7in. as compared to the previous 16.5in. by 6in. and these are the same size as the rear brake units so that total braking area for the vehicle is 1,376 sq.in.

The earlier design of braking system is retained with triple-diaphragm actuators at the front axles, single diaphragm actuators at the rear bogie and a transmission brake behind the forward front axle differential unit. Parking is through the transmission brake and for the secondary system ti secondary sections of the diaphragms on ti front axles are powered at the same tim Tyre equipment is 10.00-20, 16-ply ax because of the 2311 outer axle spre dimension on the eight-wheeler the curre maximum limit in Britain is 26 tons.

Engine and chassis The 6 x 4 tractive unit for operation at tons has a Cummins 270 bhp turbochargl engine and the same size chassis frame the six-wheel twin-steer unit but with flitch to increase the strength in the coupling are Outer axle spread of this vehicle is If making the wheelbase 12ft 6.75in. Ty equipment is 10.00-20, 16-ply all round al with a 5.75 to 1 axle ratio maximum spel is 56.2 mph and a maximum gradient of in 4.5 can be climbed at 44 tons.

As well as these exhibits on the Foder stand, there will be a further example of ti latest designs on the Neville Industrie stand. This will be a 34-ton-gross 4 x tractive unit with Cummins 205 bhp engin