I-TECH

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

BED

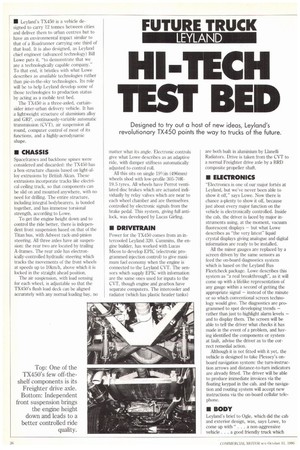

Designed to try out a host of new ideas, Leyland's revolutionary TX450 points the way to trucks of the future.

IN Leyland's TX450 is a vehicle designed to carry 12 tonnes between cities and deliver them to urban centres but to have an environmental impact similar to that of a Roadrunner carrying one third of that load. It is also designed, as Leyland chief engineer (advanced technology) Bill Lowe puts it, to demonstrate that we are a technologically capable company." To that end, it bristles with what Lowe describes as available technologies rather than pie-in-the-sky technologies. Its role will be to help Leyland develop some of those technologies to production status by acting as a mobile test bed.

The TX450 is a three-axled, curtainsider inter-urban delivery vehicle. It has a lightweight structure of aluminium alloy and GRP, continuously-variable automatic transmission (CVT), air suspension all round, computer control of most of its functions, and a highly-aerodynamic shape.

• CHASSIS

Spaceframes and backbone spines were considered and discarded: the TX450 has a box-structure chassis based on light-alloy extrusions by British Alcan. These extrusions incorporate tracks like electrical ceiling track, so that components can be slid on and mounted anywhere, with no need for drilling. The entire structure. including integral bodybearers, is bonded together, and has immense torsional strength, according to Lowe.

To get the engine height down and to control the ride better, there is independent front suspension based on that of the Titan bus, with Adwest rack-and-pinion steering. All three axles have air suspension: the rear two are located by trailing A-frames. The rear axle has electronically-controlled hydraulic steering which tracks the movements of the front wheels at speeds up to 10kmih, above which it is locked in the straight ahead position.

The air suspension, with load sensing for each wheel, is adjustable so that the TX450's flush load deck can be aligned accurately with any normal loading bay, no matter what its angle. Electronic controls give what Lowe describes as an adaptive ride, with damper stiffness automatically adjusted to control roll.

All this sits on single 191/21n (496mm) wheels shod with low-profile 305-70R19.5 tyres. All wheels have Perrot ventilated disc brakes which are actuated individually by relay valves which are near to each wheel chamber and are themselves controlled by electronic signals from the brake pedal. This system, giving full antilock, was developed by Lucas Girling.

• DRIVETRAIN

Power for the TX450 comes from an intercooled Leyland 320. Cummins, the engine builder, has worked with Lucas Micos to develop EPIC (electronic programmed injection control) to give maximum fuel economy when the engine is connected to the Leyland CVT. The sensors which supply EPIC with information are the same ones used for inputs to the CVT, though engine and gearbox have separate computers. The intercooler and radiator (which has plastic header tanks) are both built in aluminium by Llanelli Radiators. Drive is taken from the CVT to a normal Freighter drive axle by a BRD composite propeller shaft.

• ELECTRONICS "Vlectronics is one of our major fortes at Leyland, but we've never been able to show it off," says Lowe. Now there is chance a-plenty to show it off, because just about every major function on the vehicle is electronically controlled. Inside the cab, the driver is faced by major instruments using, at the moment, vacuum fluorescent displays — but what Lowe describes as "the very latest" liquid crystal displays giving analogue and digital information are ready to be installed.

All the minor gauges are replaced by a screen driven by the same sensors as feed the on-board diagnostics system which is based on the Leyland Bus Fleetcheck package. Lowe describes this system as "a real breakthrough", as it will come up with a lifelike representation of any gauge within a second of getting the appropriate signal — instead of the minute or so which conventional screen technology would give. The diagnostics are programmed to spot developing trends — rather than just to highlight alarm levels — and to display them. The screen will be able to tell the driver what checks it has made in the event of a problem, and having identified the components or system at fault, advise the driver as to the correct remedial action.

Although it is not fitted with it yet, the vehicle is designed to take Plessey's onboard navigation system: the turn-instruction arrows and distance-to-turn indicators are already fitted. The driver will be able to produce immediate invoices via the floating keypad in the cab, and the navigation and routing system will accept new instructions via the on-board cellular telephone.

• BODY

Leyland's brief to Ogle, which did the cab and exterior design, was, says Lowe, to come up with " . . a non-aggressive vehicle. . . a good friendly truck which

would not offend people . . a truck with a good image so that (for example) Marks St Spencer would he happy to operate it in a city centre . . ." The initial thought was to use a Roadrunner cab, but although the Roadrunner's basic package was preserved, the end result is completely different.

From concept sketches, which were remarkably close to the final vehicle, the next step was what Ogle's Ron Saunders

describes as" . a huge clay model" from which both the GRP cab and its interior were produced. Apart from the steel 'II' frame on which the cab is mounted and a crash bar at the front, the cab is entirely of GRP sandwich.

The exterior shape, with its sharply-tapered front, high faired roof and side skirts, was refined in the University of Southampton wind tunnel. Lowe says that this is the first truck to have been tested with rotating wheels on a moving road in such a tunnel. The result is a repeatable drag coefficient of 0.36 and a best performance — measured according to the proposed new industry standards — of 0.32, as good as that of the latest cars.

Inside (reached through sliding plugtype doors unlocked by an electronic 'key' whose signal also automatically adjusts seat and mirrors to that particular driver's own settings) the cab and controls are very different. A flat floor, swing-away steering wheel and massive headroom give true walk-through capability. The usual proliferation of stalks and dashboard switches is replaced by a series of podmounted, individually-shaped 'tactile' switches. The screen (electricallyheated) and side windows are deep, and there is a Roadrunner-inspired lower glass panel for close-up vision.

Integrated with the cab is a new-type Boalloy curtainsider body. This has a flush aluminium checker-plate floor and very slim posts to give excellent access.

• SUMMARY

Although this is a show vehicle, it is not — as both Lowe and Saunders emphasise —merely a styling exercise. It has ended up, as Lowe puts it, as "a development

tool, which is what we wanted." Those seeing it for the first time cannot fail to be impressed by the exceptional standards of chassis construction and finish and of the detail in a one-off cab and body.

1=1 By Allan Winn