CONVERSION TO COAL-GAS.

Page 16

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

Hints and Wrinkles to Garage Proprietors on Fitting-out.

A Note of Warning.

The keen desire to secure a means of carrying as under high compression is stimulating inventive effort to a striking degree. While we have no desire to curb this enthusiasm we feel that it would not be out of place to utter a word of warning, especially to those enthusiastic investigators whose zeal and imperfect knowledge of the enormous pressures set up by the gas may outrun their discretion. Grave risk is incurred in compressing the gas to a high degree. When, for instance, we speak about a pressure of 125 atmospheres—over 1800 lb. to the sq. in.—we are apt to regard the matter lightly and to ignore the enormous strain which is being imposed upon the metal, which is in excess of 12 tons per sq. in. When weld1ess tubes are being used, the risk perhaps is not very great. Now it is better to be cafe than sorry. So the inexperienced experimenter would be wise to proceed warily, and not essay to submit any steel tubing that may come to hand, merely because it happens to be tubing, to the test of compression, because ordinary welded tubing is certain to collapse under the strain and might precipitate a very serious accident.

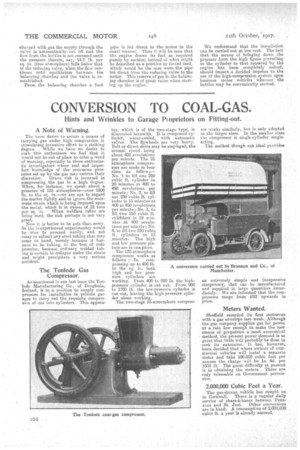

The Tonlode Gas Compressor.

As mentioned in our last issue the Tonlode Manufacturing Co., of Drogheda, Ireland, is in a position to supply compressors for installation in private garages to carry out the requisite compression of aas into cylinders. This appara tus, which is of the two-stage type', is illustrated herewith. It is compound cylinder, water-cooled, with automatic valves. The flywheels are very heavy. Belt or direct drive may be empleyed, the normal speed being about 400 revolutions per minute. The 25 atmosphere compressors are made in four sizes as follow :-No. 1 to fill one 250 cubic ft. cylinder in 20 minutes at 400 to 450 revolutions per minute ; No. 2, to fill one 250 cubic ft. cylinder in 15 minutes at 490 to 450 revolutions per minute ; No. 3, to fill two 250 cubic ft. cylifiders in 18 minutes at 400 revolutions per minute; No. 4, to fill two 250 cubic ft. cylinders in 15 minutes. The high and low pressure pistons are in one piece.

The 129-atmosphere compressor works as

follows :—In cornpressing up to 409 lb. to the sq. in. both high and low pressure cylinders are working. From 400 to 900 lb. the highpressure cylinder is cut out. Frern 900 to 1700 lb. the low-pressure cylinder is cut out, leaving the high-pressure cylinder alone working.

The two-stage 25-atmosphere compres

sor works similarly, hut is only adopted in the larger sizes. In the smaller sizes the compressor is single-cylinder singleacting. The method though net ideal provides an extremely simple and inexpensive compressor, that can be manufactured and supplied in large quantities immediately. We are informed that the compressors range front 222 upwards in price.

Meters Wanted..

Sheffield recorded its first motorvan with a gas envelope last week. Although the gas company supplies gas for power at a rate low enough to make the new means of propulsion a most economical method, the present power demand is se great that little will probably be done to seek its extension. It has, however, been decided that where owners of cornniereiel vehiclee will instal a separate meter and take 100,000 cubic feet per annum the charge will be 1s. Ad. per 1000 ft. The great difficulty at present is in obtaining the meters. These are onlly releasable on Government permission,

2,000,000 Cubic Feet a Year.

The gas-driven vehicle has caught on in Cornwall. There is a regular daily service of chars-it-bancs between Penz

ance and St. Just. Other conversions are in hand. A consumption of 2,000,000 cubic ft. a year is already assured.

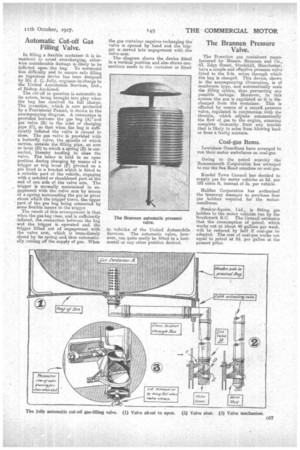

Automatic Cut-off Gas Filling Valve.

In filling a flexible container it is incumbent to avoid overcharging, otherwise considerable damage is likely to be inflicted upon the bag. To surmount this difficulty and to ensure safe filling an ingenious device has been designed by Mr. J. C. Jolly, engineer-in-charge to the United Automobile Services, Ltd., of Bishop Auckland.

The cut-off in question is automatic in its action' being brought into play when the bag has received its fall charge. The invention which is now protected by a Provisional Patent, is shown in the accompanying diagram. A connection is provided between the gas hag (A)and gas valve (B) in the inlet or charging pipe (0)? so that when the bag is sufficiently inflated the valie is caused to close. The gas valve is provided with a butterfly valve, the spindle of which carries, outside the filling pipe, an arm or lever (D) to which a spring (E) is connected, thereby tending to close the valve. The latter is held in an open position during charging by means of a trigger or trip lever (F) pivoted on a pin fixed in a, bracket which is fitted to a suitable part of the vehicle, engaging with a notched or shouldered part at the end of one side of the valve arm. The _ trigger is normally maintained in engagement with the valve arm by means of a spring surrounding the pin or pivot about which the trigger turns, the upper ' part of the gas bag being Oonnec t e a by some flexible means to the trigger.

The result of this arrangement is that when the gas bag rises, and is sufficiently inflated, the connection between the bag and the trigger is operated and the trigger lifted out of engagement with the valve arm, which is immediately closed by its spring and, thus automatically cutting off the supply of gas. When the gas container requires recharging the valve is opened by hand and the trigger is moved into engagement with the valve arm.

The diagram shows the device fitted in a vertical position and also ahows connections made to the container as fitted to vehicles of the United Automobile Services. The automatic valve, however, can quite easily be fitted in a horizontal or any other position desired.

The Brannen Pressure Valve.

The fl-section gas containerS manufactured by Messrs. Brannen. and Co., %43, Edge Street, Shudehill, Manchester, have a simple and effective pressure valve fitted to the 2-in, union through which the bag is charged. This device, shown in the accompanying illustration is of mushroom type, and automatically seals the filling orifice, thus preventing any possible leakage. Moreover, in this system the gas is regulated as it is -discharged from the container. This is effected by means of a recora pressure valve, regulated in conjunction with the throttle, which adjusts automatically the flow of gas to the engine, ensuring complete immunity from any trouble that is likely to arise from blowing back or from a faulty mixture.

Coal-gas Items.

Lewisham Guardians have arranged to run their motor ambulance on coal-gas.

Owing to the petrol scarcity the Bournemouth Corporation has arranged to run the Sea Road omnibus on coal-gas.

Kendal Town Council has decided to supply gas for motor vehicles at 5d. per 100 cubic ft. instead of 3s, per vehicle.

Halifax Corporation has authorised the tramway manager to purchase four gas holders required for the motoromnibuses.

Straker-Squire, Ltd., is fitting gas holders to the motor vehicles run by the Southwark B.C. The Council estimates that. the consumption of petrol, which works out at about 40 gallons per week, will be reduced by half if coal-gas be adopted. The cost of coal-gas works out equal to petrol at 9d. per gallon at the present price.