Superheated Steam : Article No. II.

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

By David J. Smith.

In considering the application of superheated steam to commercial motor vehicles, the first point to be settled is how the steam is to be superheated. There are two methods : (i) generation of the steam in an ordinary boiler, and its superheating in coils after it has left the boiler on its way to the engine ; and (2) the completion of both stages in a socalled " flash " boiler. The first method would, naturally, be the one adopted in any conversion of existing vehicles, unless the old boiler was worn out, and a new one had to be fitted, when a flash boiler could be substituted if desired. The second method would only be adopted in the construction of new vehicles.

In fitting a superheater to existing boilers, several points must be carefully noticed, in order that no damage may be clone to the engine. 'The ordinary double-acting steam engine, fitted with glands and slide or piston valves, will not stand a high degree of superheat without giving much trouble. If has been proved, however, by experience with this type of engine on steam cars, that a degree of superheat sufficient to give an economy of 33 per cent. may be safely applied, and this is more than sufficient to make the question of superheat on commercial vehicles an important one. Apart from the question of saving in fuel, the fact that the effective radius of a vehicle on its tank of water is nearly doubled makes steam vehicles possible on routes that could hardly be considered in view of the difficulties of obtaining water on the road.

The temperature of the steam should not exceed 6000 Fahr. in average running, if no trouble is to be given by glands, slide valves, and lubrication. This is fairly easily accomplished with ordinary boilers having superheater attachments, and can be done with a flash boiler, but it is preferable, when using flash boilers, to adopt a special type of engine, as the full advantage may then be taken of superheat without fear of damage. An increasing proportion of steam motors are now being built with the locomotive type of boiler, as there is no doubt that many of the vertical fire and water tube boilers fitted to steam wagons were simply fuel wasters, and that they drove the engines on hot water, so bad was the priming. To such boilers as these, the fitting

of a superheating coil proved to work wonders. The cost of fitting a superheater is very slight, and there is no question that the cost would be recovered almost on the first month's running that followed the addition.

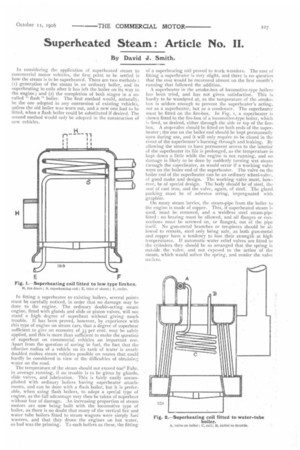

A superheater in the smoke-box of locomotive-type boilers has been tried, and has not given satisfaction. This is hardly to be wondered at, as the temperature of the smokebox is seldom enough to prevent the superheater's acting, not as a superheater, but as a condenser. The superheater must be fitted on the fire-box. In Fig. i, a superheater is !ihown fitted to the fire-box of a locomotive-type boiler, which is fired, as desired, either through the side or top of the firebox. A stop-valve should be fitted on both ends of the superheater ; the one on the boiler end should be kept permanently open during use, and it will only require to be closed in the event of the superheater's burning through and leaking. By allowing the steam to have permanent access to the interior of the superheater its life is prolonged, as the temperature is kept down a little while the engine is not running, and no damage is likely to be done by suddenly turning wet steam through the superheater, as would occur if a working valve were on the boiler end of the superheater. The valve on the boiler end of the superheater can be an ordinary wheel-valve, of good make and design. The working valve must, however, be of special design. The body should be.of.steel, the seat of cast iron, and the valve, again, of steel. The gland packing must be of asbestos string, impregnated with graphite.

On many steam lorries, the steam-pipe from the boiler to the engine is made of copper. This, if superheated steam is used, must be removed, and a weldless steel steam-pipe fitted : no brazing must be allowed, and all flanges or connections must be screwed on, or flanged, out of the pipe itself. No gun-metal branches or tee-pieces should be allowed to remain, steel only being safe, as both gun-metal and copper have a tendency to lose their strength at high temperatures. If automatic water relief valves are fitted to the cylinders they should be so arranged that the spring is outside the valve, and not exposed to the action of the steam, which would soften the spring, and render the valve useless. Once steam is generated, it requires a very small amount of heat to superheat it, and the superheat can, therefore, he as easily lost. The steam pipe from the superheater to the engine should be specially wed covered with non-con

ducting material. The size of the steam-pipe can, with superheated steam, be greatly reduced, as the velocity of superheated steam is much greater than that of saturated steam of the same pressure. The friction on ports and valves is, also, greatly reduced, which accounts for the extra speed and power that can be obtained by supplying .superheated steam to any given engine. The quantity or number of square feet of heating surface that is required varies with the type of boiler. It would be less in the locomotive-type boiler (Fig. 1), than in the water-tube boiler (Fig. 2) which gives very wet steam indeed. Where the superheater is placed in the fire-box, it can be taken as an average rule that there should be 2 square feet of superheating surface for every tocilb. of water evaporated per hour. At starting, when the full power of steam is taken through the superheater, the temperature may fall below what is desired, say, to 3sodef.e„. or 400deg. Fehr., but, when the engine is on its normal work, and only a small flow of steam is passing through the superheater, the temperature rises, and, if a control or driving valves were fitted at the boiler aide of superheater' this elevation may reach to dangerous limits, As steam from the boiler has full access to the superheater, a circulation is set up, and the steam in the superheater never gets to the high temperature that it would attain if a small stream only, though sufficient to supply the engine, were allowed to pass through it. The life of a superheating coil, made from .gths-inch by i-inch steel tube, is about 14 to r8 months.

In many lorries, the steam demands of the engine are often too much for the boiler, and the feed-puinps on others are not large enough to keep the boiler supplied with water unless recourse is had to either an injector or a separate donkey-pump. In both these cases, the superheater is valuable. In a test recently made, a wagon was able to run 22 miles on its supply of water.

THE ADDITION OF A SUPERHEATER increased this to 38 miles, or nearly double. This improvement, of course, halved the work of the feed-pump, put much less work on the boiler, and greatly reduced the fuel consumption. In Fig, 2 is shown a superheater fitted to a vertical water-tube boiler. This would, besides superheating, add to the efficiency of this boiler by breaking up the lire gases and distributing them more evenly among the tubes. This type of boiler is, of course, very inefficient, as nearly all the heating surface is vertical, or only of one half the value of any horizontal surfaces over the fire.

With wet steam, the lubrication of the cylinders of the engine presents no difficulties. In fact, in several cases, the drivers have not known how to work the complicated, sight, drip-feed lubricator fitted, and engines have, therefore, as far as cylinders were concerned, gone without, the driver giving the big-ends or cross-heads an extra allowance of oil instead ! In using superheated. steam, however, lubrication must be of the first importance --not the last, as on so many vehicles. Oil of a very high flash point must be used. There are several oils made especially for this work, and only these should be employed. The sight-feed, displacement lubricator must be abandoned, as this, with superheated steam, is not reliable. ln fact, when the steam is at its maximum temperature, the flow of oil, which should then heat its greatest, decreases, as the steam does not condense so readily. A positive, pump-feed lubricator must be used, and this must deliver the oil into the main steampipe, just before it enters the valve chest. It must not be inserted into the valve chest, as, then, the oil simply runs down the walls of the chest, and very little ever enters the cylinders. The necessary form of lubricator is driven by a shaft, or rocking lever, off the engine itself, and should be fixed in front of the driver, in order that he may both note its working and give it a few strokes, by hand, before starting the engine for the day, or after every long stop. The automatic oil-pump delivers

A FIXED QUANTITY OF OIL, at regular intervals, and the supply can be renewed instantly, with the engine running. Engines working on highly superheated steam, with this method of lubrication, have shown no signs of wear after four years of regular service.

With the moderate temperature of steam advocated, the slide valves or piston-valves will give no trouble, if the above method of lubrication is adopted. The whole trouble with slide-valves, and moderately superheated steam, is caused by defective lubrication. The glands must be packed with special packing, to resist the superheat, and both glands and bushes must be a good fit. If glands are worn, and are detachable from the covers, the new glands can, with advantage, be made longer, if space allows. Some forms of metallic packing melt out of the glands at the first suspicion of superheat. Packing suitable for superheated steam is, however, readily obtainable.