A Built-up Connecting Rod

Page 206

If you've noticed an error in this article please click here to report it so we can fix it.

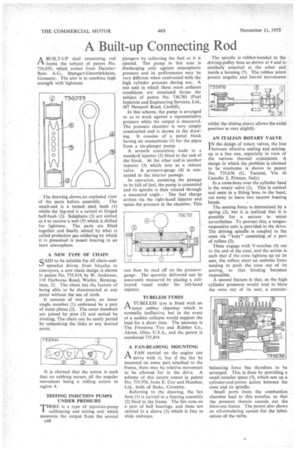

A BUILT-UP steel connecting rod 1"-1 forms the subject of patent No. 736,033, which comes from DaimlerBenz A.G:, Stuttgart-Untertiirkheim, Germany. The aim is to combine high strength with lightness.

The drawing shows an exploded view of the parts before assembly. The small-end is a turned steel bush (1) whilst the big-end is a turned or forged half-bush (2): Sideplates (3) are slotted at 4 to receive a web (5) which is drilled for lightness.. The parts are fitted together and finally united by what is called protective• gas soldering by which it is presumed is meant brazing in an inert atmosphere.

A NEW TYPE OF CHAIN

SAID to be suitable for all chain-andsprocket drives, from bicycles to conveyors, a new chain design is shown in patent No. 735,919, by W. Anderson, 118 Harborne Road, Warley, Birmingham, 32. The chain has the feature of being able to be disconnected at any point without the use of tools.

It consists of two parts, an inner single member (I) embraced by a pair of outer plates (2). The outer members are joined by pins (3) and united by riveting. The chain can be easily parted by unhooking the links at any desired point. • It is claimed that the action is such that no rubbing occurs, all the angular movement being a rolling action in region 4.

TESTING INJECTION PUMPS UNDER PRESSURE THERE is a type of injection-pump calibrating and testing unit which measures the output from the several c48

plungers by collecting the fuel as it is ejected. The pump in this case is discharging only against atmospheric pressure and its performance may be very different when confronted with the high cylinder pressure during use. A test unit in which these more arduous conditions are simulated forms the subject of patent No. 736,781 (Fuel Injection and Engineering Services, Ltd., 387 Newport Road, Cardiff).

In this scheme, the pump is arranged so as to work against a representative pressure while the output is measured. The pressure chamber is very simply constructed and is shown in the drawing. It consists of a metal block having six connections (1) for the pipes from a six-plunger pump.

A seventh connection leads to a standard injector (2) fitted to the end of the block. At the other end is another injector (3) which acts as a release valve. A pressure-gauge (4) is connected to the interior passage.

In operation, assuming the passage to be full of fuel, the pump is connected and its spindle is then rotated through a measured angle.. The fuel charge arrives via the right-band injector and raises the pressure in the chamber. This can then be read off on the pressure' gauge. The quantity delivered can be accurately measured by placing a calibrated vessel under the left-hand injector.

TuBEIRSS TYRES

A TUBELESS tyre is fitted with an r% inner rubber chamber which is normally ineffective, but in the event of a sudden collapse would support the load for a short time. The patentee is The Firestone Tire and Rubber Co., Akron, Ohio, U.S.A., and the patent is numbered 735,854.

A FAN-BEARING MOUNTING A FAN carried on the engine can move with it, but if the fan be mounted on some part attached to the frame, there may be relative movement to be allowed for in the drive. A scheme of this nature comes in patent No. 735,976, from E. Coy and Humber, Ltd., both of Stoke, Coventry.

Referring to the drawing, the fan boss (I) is carried in a bearing assembly (2) fixed to the frame. The fan runs on a pair of ball bearings, and these are carried in a sleeve (3) which is free to slide endways. The spindle is rubber-bonded to the driving-pulley boss as shown at 4 and is similarly attached at the other end inside a housing (5). The rubber joints permit angular and lateral movements whilst the sliding sleeve allows the axial position to vary slightly.

AN ITALIAN ROTARY VALVE TN the design of rotary valves; the line I between effective sealing and seizingup is a fine one, especially in view of the various thermal expansions. A design in which the problem is claimed to be overcome is shown in patent No. 735,636 (G. Tacconi, Via di Castello 2, Firenze, Italy), In a cross-bore over the cylinder head is the rotary valve (1). This is conical and seats in a fitting bore in the head, cut away to leave two narrow bearing bands.

The seating force is determined by a spring (2), but it is realized that it is possible for a seizure to occur nevertheless. To prevent this, a torqueresponsive unit is provided in the drive. The driving spindle is coupled to the cone via " keys" consisting of a pair of rollers (3).

These engage with V-notches (4) cut in the end of the cone, and the action is such that if the cone tightens up on its seat, the rollers exert an endwise force tending to push the cone out of its seating, so that binding becomes impossible.

A second feature is that, as the high cylinder pressures would tend to blow the cone out of its seat, a counter balancing force has therefore to be arranged. This is done by providing a small annular space (5), which sets up a cylinder-and-piston action between the cone and its spindle.

Small ports from the combustion chamber lead to this annulus, so that the pressure therein cancels out the blow-out forces. The patent also shows an oil-circulating system for the lubrication of the valve,