New British Rubber-bonded Suspension System

Page 106

Page 109

If you've noticed an error in this article please click here to report it so we can fix it.

BASED on the S9 underfloorengined chassis, a " Midland Red" single-deck bus with Metalastik toggle-link rubber susPension fitted to the rear Ale was demonstrated in Birmingham on Wednesday. The success of the experiment may`establish the new system as a revolutionary development. By : co-ordinating design, enterprise With exhaustive operational testing, The Birmingham and Midland Motor _ Omnibus Co., Ltd., has remained in the forefront as a pioneer of vehicle progress since the early days of road-passenger transport, .and the official appearance of the toggle-link on a " Midland Red" vehicle is :in .itself a

stuarantee of performance. . .

In any vehicle. with' a high loadcarrying capacity relative to -its tare weight, constant-stiffness . suspension cannot provide satisfactory springing at all load variations, as light-load, comfort must be sacrificed to full-load safety. With a constant,periodicity spring, the stiffness increasesin proportion to load increments, and a substantially .uniform performance is achieved in terms of vertical deflection: Simple Construction

In many attempts to introduce such a system, the designs have been complex and costly, and have possessed a . limited resistance to rolling. ' The. Metalastik spring is simple in construction and the deflection-load curve approximates to the constant periodicity curve over the positive displacement range, with the added advantage that its resistance increases more rapidly from " laden" to "overload." Particular attention has been paid to roll stiffness and lateral stability. • Rubber as a spring material can store more energy for a given weight than

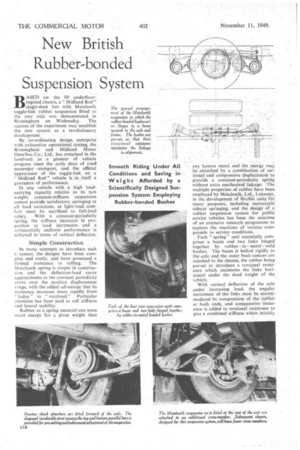

any known metal. and. the energy may he .abSOthed, by a' combination of tor: soiiarand compressive displacemetit to Provide a constant-periodicity' Spring without extra mechanical linkage. The multiple properties of tubber have been employed by Metalastik, Ltd.,. Leicester, in the development of flexible "units for many purposes,including motorcycle sidecar springing, and the design' of a' rubber suspension systemfor publid service vehicles has. been the outcome of an extensive research:vrogramme 'to explore the reactions of various compounds to service ,conditions. , Each "spring" unit essentially comprises -a beam and two links hinged together by rubber to metal weld bushes. The heath is bolted rigidly to the axle and the outer: bush centres are attached to the chassis, the rubber being pre-set to introduce a torsional resistance which maintains the links horizontal under the dead weight of the vehicle.

With vertical deflection of the axle under increasing load, the angular movement of the links must be aecommodated by compression of the rubber • both ends, and -compressive'resistance is added to torsional resistance to give a combined stiffness which initially

increases in proportion to the loading and subsequently increases at a higher rate, On rebound, the stiffness similarly increases with deflection, which assists damping and counteracts excessive roil when cornering.

AS the toggle-link suspension was fitted to an existing type of chassis, full advantage could not be taken of the reduced weight of the rubber elements as compared with the leaf springs. To anchor the outer bushes, additional cross-members are employed which duplicate existing members, but when a chassis has been designed specifically to. incorporate the necessary modifications, a large saving in weight will obviously be achieved.

The two bushes in a link are rigidly joined by top and bottom parallel bars and a diagonal turnbuckle strut. The bars are jointed to the hushes at theends, which allows relative angular movement for pre-setting or adjustment by varying the strut length. The maximum compressive displacement is 51 ins.

An important feature of the system is the method used to increase lateral

stability. The beams are parallel to the horizontal axis of the vehicle, but beams and cross-members are cranked at their ends to position the links at an angle to the axis, This " splaying " of the links ensures that a part of any side thrust acts as a compressive force between centres and reduces the shear stress on the rubber.

Box-section Beams

The beams are of box section and attached to the axle by the standard leaf-spring bolts. Brake arcing is controlled by torque arms, each of which is jointed to the beam above the axle and to a lug on the outside of the main chassis member approximately 3 ft. 6 ins. in front of the beam centre. All the torque arm bushes are fed with oil from the chassis automatic lubrica:citt system, The hand-brake linkage comprises a cross-shaft and tension rods connected to the upper ends of the Lockheed hydraulic-servo brake levers. The crossshaft is located slightly to the rear of the front torque-arm pivot point to obviate any variance of brake application with load resulting from the brake lever being behind the axle: NeWton shock absorbers are employed, the extra brackets for which being the only non-standard axle fittings.