Travelling Workshops for Iraq

Page 90

If you've noticed an error in this article please click here to report it so we can fix it.

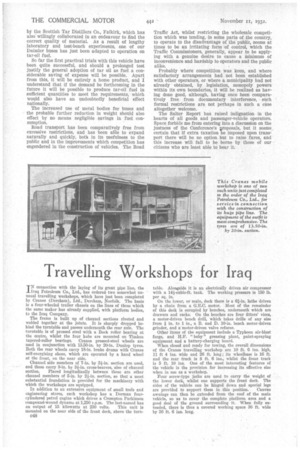

IN connection with the laying of its great pipe line, the Iraq Petroleum Co., Ltd., has ordered two somewhat unusual travelling workshops, which have just been completed by Cranes (Dereham), Ltd., Dereham, Norfolk. The basis is a four-wheeled trailer chassis on the lines of those which the same maker has already supplied, with platform bodies, to the Iraq Company.

The frame is built up of channel sections riveted and welded together at the joints. It is sharply dropped behind the turntable and passes underneath the rear axle. The turntable is of pressed steel with a Bock roller bearing at the centre, whilst the four hubs are mounted on Timken tapered-roller bearings. Cranes premed-steel wheels arc used in conjunction with 13.50-in. by 20-in. Dunlop tyres. Both the rear wheels carry 18-in. brake drums with Cranes self-energizing shoes, which are operated by a hand wheel at the front, on the near side.

Channel side members of 7-in. by 3i-in. section are used, and these carry 9-in. by 3i-in. cross-bearers, also of channel section. Placed longitudinally between these are other channel members of 5-in. by 2i-in. section, so that a most substantial foundation is provided for the machinery with which the workshops are equipped.

In addition to an extensive equipment of small tools and engineering stores, each workshop has a Dorman fourcylinderecl petrol engine which drives a Crompton Parkinson compound-wound dynamo at 1,250 r.p.m. The last-named has an output of 15 kilowatts at 230 volts. This unit is mounted on the near side of the front deck, above the turn. o48 table. Alongside it is an electrically driven air compressor with a 14i-cubic-ft. tank. The working pressure is 150 lb. per sq. in.

On the lower, or main, deck there is a 6/-in. lathe driven by a chain from a G.E.C. motor. Most of the remainder of this deck is occupied by benches, underneath which are drawers and racks. On the benches are four fitters' vices, a motor-driven bench drill, which takes drills of any size from in. to 1 in., a B. and D. 10-in, bench motor-driven grinder, and a motor-driven valve refacer.

Other items of the equipment include a Typhoon air-blast forge, and H.F. " baby" greasing plant, paint-spraying equipment and a battery-charging board.

When closed and ready for towing, the overall dimensions of the Cranes travelling workshop are 10 ft. 6 ins. high, 11 ft 4 ins. wide and 26 ft. long; its wheelbase is 16 ft. and the rear track is 8 ft. 6 ins., whilst the front track is 5 ft. 10 ins. One of the most interesting features of the vehicle is the provision for increasing its effective size when in use as a workshop.

Four screw-type jacks are used to carry the weight of the lower deck, whilst one supports the front deck. The sides of the vehicle can be hinged down and special legs

are provided to support them in this position. Canvas awnings can then be extended from the roof of the main vehicle, so as to cover the complete platform area and a good deal of the ground surrounding it. When fully extended, there is thus a covered working space 30 ft. wide by 36 ft. 6 ins. long.