Trailer abuse: a too-common vice

Page 121

Page 122

If you've noticed an error in this article please click here to report it so we can fix it.

The trailer is often neglected and mere are some areas which even ne Minis-Ty test does not touch. Bill Brock advises you to do more an e minimum. BOX REEFER, skeletal or flat — no matter which — the trailer is likely to be the most undermaintained piece of equipment of any in the fleet. I have purposely not included tankers or low-loaders, because more often they remain: if not attached, at least in close proximity to the prime mover for most of the time, thus benefiting from the same servicing schedules.

With an average of 2.5 semitrailers to each tractive unit, at any one time there are a vast number standing unattached awaiting loading or unloading. Some are even being serviced. Generally they do fewer miles than the tractive unit; consequently preparation for the Ministry's annual test may be its own claim to regular servicing.

Even for the simplest design of trailer, there are parts which are prone to wear or damage. The king-pin in various forms is less likely to wear than the jaws of the fifth wheel. Continuous coupling and uncoupling or shunting back and forth when used with worn jaws eNientually takes its toll.

Easily replaceable is the bolt-in type with eightor sixhole fixings in the base plate. There is also a stud type which can be bolted. Often a worn kingpin will need a bit of heat applied before it can be removed. Similarly one type of welded pin has a base plate, the other a stud and collar.

Moving along the chassis, the park brake works better with a little lubrication. There are three moving parts here prone to wear, the pawl. the ratchet and the cable. Staying with the system and going to the front of the vehicle the air-brake couplings, when worn, can lead to a leak in the system.

Two types of connector are in common use. The palm type is more frequently found on European vehicles, while the male and female 'C' type is fit ted to UK vehicles. The two are incompatible. Where selfsealing valves are used, it has been known for the insert to be removed.

For vehicles working with both British and Continental trailers, it must be worthwhile, if not essential, to carry a set of ready make-up adaptors. Air tanks, if not fitted with an automatic drain valve, need to does nothing for braki efficiency.

If easily accessible, manually-operated lever-ty tap will suffice. For tanks

Below: Brake connectors are otten inaccessible places, an altel abused and can lead to leaks in the air ative spring-loaded type, co brake system. plete with cable, will do the j

equally well.

Whether triple, double single diaphragm, the bra chambers are a likely source trouble at some time in ti vehicle's life, if only through worn fulcrum pin in the yoke.

Load-sensing valves, in r experience, are constantly i correctly fitted both on tracti units, trailers and rigid vehicIE even if installed at the facto' Many service schedules do n include them as a matter course, and they don't even g checked during the Ministry i spection.

The suspension often corn in for a hammering. Leaf sprini are still used more than al continued overle

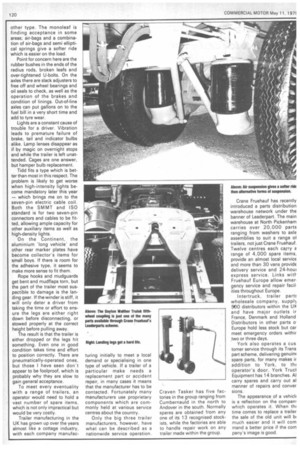

other type. The monoleaf is finding acceptance in some areas; air-bags and a combination of air-bags and semi elliptical springs give a softer ride which is easier on the load.

Point for concern here are the rubber bushes in the ends of the radius rods, broken leafs and over-tightened U-bolts. On the axles there are slack adjusters to free off and wheel bearings and oil seals to check, as well as the operation of the brakes and condition of linings. Out-of-line axles can put gallons on to the fuel bill in a very short time and add to tyre wear.

Lights are a constant cause of trouble for a driver. Vibration leads to premature failure of brake, tail and indicator bulbs alike. Lamp lenses disappear as if by magic on overnight stops and while the trailer is left unattended. Cages are one answer, but hamper bulb replacement.

Tidd fits a type which is better than most in this respect. The problem is likely to get worse when high-intensity lights become mandatory later this year — which brings me on to the seven-pin electric cable coil. Both the SMMT and ISO standard is for two seven-pin connectors and cables to be fitted, allowing ample capacity for other auxiliary items as well as high-density lights.

On the Continent, the aluminium 'long vehicle' and other rear marker plates have become collector's items for small boys. If there is room for the adhesive type, it seems to make more sense to fit them.

Rope hooks and mudguards get bent and mudflaps torn, but the part of the trailer most suspectible to damage is the landing gear. If the winder is stiff, it will only deter a driver from taking the time or effort to ensure the legs are either right down before disconnecting, or stowed properly at the correct height before pulling away.

The result is that the trailer is either dropped or the legs hit something. Even one in good condition takes time and effort to position correctly. There are pneumatically-operated ones, but those I have seen don't appear to be foolproof, which is probably why they are slow to gain general acceptance.

To meet every eventuality with a range of trailers, an operator would need to hold a vast number of spare items, which is not only impractical but would be very costly.

Trailer manufacturing in the UK has grown up over the years almost like a cottage industry, with each company manufac turing initially to meet a local demand or specialising in one type of vehicle. If a trailer of a particular make needs a replacement part or accident repair, in many cases it means that the manufacturer has to be contacted. Fortunately many manufacturers use proprietary components which are commonly held at various service centres about the country.

Only the big three trailer manufacturers, however, have what can be described as a nationwide service operation. Craven Tasker has five factories in the group ranging from Cumbernauld in the north to Andover in the south. Normally spares are obtained from any one of its 13 recognised stockists, while the factories are able to handle repair work on any trailer made within the group. Crane Fruehauf has recently introduced a parts distribution warehouse network under the banner of Leaderpart. The main warehouse at North Pickenham carries over 20,000 parts ranging from washers to axle assemblies to suit a range ol trailers, not just Crane Fruehauf. Twelve centres each carry a range of 4,000 spare items, provide an almost local servicE and more than 30 vans providE delivery service and 24-houi express service. Links with Fruehauf Europe allow emer. gency service and repair facil. ities throughout Europe.

I ntertruck, trailer parts wholesale company, suppl) %0 distributors within the UK and have major outlets ir France, Denmark and Holland Distributors in other parts a Europe hold less stock but car meet emergency orders withir two or three days.

York also operates a cus tomer service through its Trans part scheme, delivering genuin( spare parts, for many makes ir addition to York, to th( operator's door. York Trucl Equipment has 14 branches. Al carry spares and carry out al manner of repairs and conver sions.

The appearance of a vehicli is a reflection on the compan, which operates it. When thi time comes to replace a trailer the sale of the old unit will bi much easier and it will corn mand a better price if the com pany's image is good.