For DRIVERS, MECHANICS & FOREMEN.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS is paid to the sender of any letter which we publish on this page, and an EXTRA FIVE SHILLINGS to the sender of the one which we select as being the best each week. All notes are edited before being published. Mentionyour employer's name, in confidence, as evidence of good faith. Address. D., M. and F„ "The Comnierciat Motor," 7-15, Bosebery Avenue, London, E.G. 1.

Lamps Alight.

On Saturday, May 15th, light your lamps at 9.13 in London, 9.47 in Edinburgh, 9.35 in Newcastle, 9.34 in Liverpool, 9.23 in Birmingham, 9.23 in Bristol, a)std 10.17 in Dublin.

Repairing Steering Arms.

The sender of the following commuvication Iy..as been awarded the extra payment of 5s. this week. [2085] " Mechanic " (Honey) writes : —" Steering arms and their ball pins are a frequent .cause of trouble on heavy wagons. After a time they are apt to work loose and it is generally discovered that the holes into which the steering arms or ball pins fit have also. worn and that renewal of the arms or pins, would mean, that the stub axles or steering arms respectively would also have to be replaced ; altogether a tedious job. ,

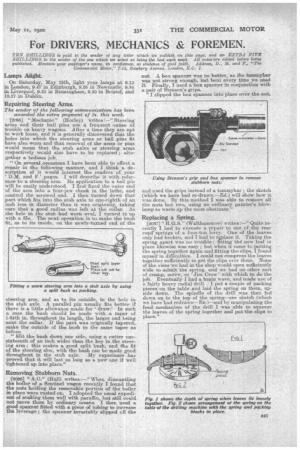

" On several occasions I have been able, to effect a repair in the following manner, and I think a. description of it would interest the readers of your D.M. and F.' pages. I will describe it with reference to a steering arm. Its application to a ball pin will be easily understood. I first fixed the outer end of the arm into a four-jaw chuck in the lathe, and centred the screwed end. I then turned down that part which fits into the stub axle to one-eighth of an inch less in diameter than it was originally, taking care that a good radius was left at the collar. As the hole in the stub-had worn oval, I turned itwith a file. The next operation is to make the bush. fit, as to its inside, on the newly-turned end of the Fitting a worn steering arm into a stub axle by using a s;olit bush as packing.

• steering arm, and as to its outside, in the hole in the stub axle. A parallel pin usually fits better if there is a little allowance made for draw.' In such a case the bush should be made with a taperof 1-64th in. throughout its length, the larger end being . next the collar. If the part was originally tapered, make the outside of the hush to the same taper as before.

"Slit the, bush down one side, using a cutter onesixteenth of an inch wider than the key in the steering arm; this makes a good split bush, and the fit of the steering am, with the bush can be made good throughout in the stub axle. My experience has proved that it will last. as long as a hew one if well tightened up into place."

Removing Stubborn Nuts.

p0t3ej " A.0." (Hull) writes:—" When dismantling the boiler of a Sentinel wagon recently I found that the nuts holding the removable portion of the boiler in place were rusted on. I adopted the usual expedient of soaking them well with paraffin, but still could not move them by ordinary means. I then used a. good spanner fitted with a Frieze of tubing to increase the leverage ; the spanner invariably slipped elf the nut. A box spanner was. no better, as the toramybar -was not strong enough, but bent every time we used it. Finally, I used a box spanner in conjunction with a pair of Stenson's grips.

I slipped the box spanner into place over the nut,

and used the grips instead of a tcainmybar ; the sketch (which we have had re-drawn.—Ed.) will show how it was done. by this method I was able to remove all tbe nuts but two, using an ordinary painter's blow-

lamp' to warm n up the most obstinate."

Replacing a Spring.

[2087] " H. G. S." (Walthamstow) w rites. —" Quite recently I had to execute a repair to one of the rear road springs or a four-ton lorry. One of the leaves only had broken, and I had to 1-2.jal.ace it. Taking the spring apart was no trouble ; fitting th4 new leaf in place likewise was easy ; but when it came to putting the spring together again and fitting the clips, I found myself in difficulties. I could not compress the leaves together sufficiently to get the clips over them. None of the vices we had in the shop would open sufficiently wide to admit the spring, and we had no other sort of cramp, screw, or 'Jim Crow' with which to do the job. Eventually I had a brain wave, and made use of a fairly heavy radial drill. I put a couple of packing pieces on the table and laid the spring on them., upside down. The spindle of the drill was then fed down on to the top of the spring—see sketoh (which we have had redrawn—ED.)—and by manipulating the feed mechanism of the drill I was able to squeeze • the leaves of the spring together and put the clips in place."