HINTS ON MAINTENANCE.

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

495.—An Improvement to the Drive for the Dennis Oil Pump.

Owing to the difficulty of removing the oil-pump shaft from the aluminium casting on the engine of a subsidy A-type Dennis chassis, the following method was adopted when renewing the brass bush in this casting.

The casting was rebored to clear the top collar, and the bush. turned•to suit the rebored hole. The advantage claimed is that the skew gear or dog sleeve need not be moved on the shaft to effect hush replacement once the alteration has been carried out., as the shaft complete can then be pressed from the casting.

496.—Preventing Choking of the Petrol Pipe on the Hallford.

• There is a small sump or well at the bottom of the petrol tank on the Hanford vehicle. This is provided In order to allow use being made of the full amount of petrol in the tank. Unfortunately, it sometimes has the effect of collecting any water or dirt which may be in the petrol, and this often chokes the petrol pipe and even the filter.

In order to avoid having frequently to clean these parts, in one instance the pipe was removed from the tank and a piece of copper tube about LI ins. long and in. diameter was soldered to the upper portion of the connection, so that when it was replaced in the tank this copper pipe projected about :1. in. above the level of the sump. This allows the dirt and water to collect, and it can be removed occasionally at convenient times instead of causing stoppages on the road.

497.—Making an Efficient Breather for a Peerless Engine.

It not infrequently occurs that when Overhauling a Peerless vehicle it is discovered that the breather is missing from the crankcase, its place often being taken by a solid cap.

It should be well known that a breather is a .D413

necessity. If not provided, there is a risk of pressure in the crankcase causing oil leaks by forcing oil through the joints. Also, oil may be forced up the sides of the cylinders and past the rings, causinga smoky exhaust and large consumption of oil.

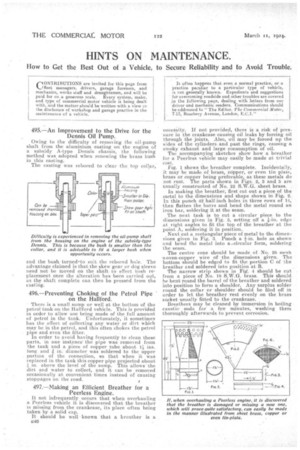

The accompanying sketches show how a breather for a Peerless vehicle may easily be made at trivial cost.

Fig. 1 shows the breather complete. Incidentally, it may he made of brass, ccipper, or even tin plate, brass or copper being preferable, as these metals do not rust. The parts shown in Figs. 2, 3 and 5 aro usually constructed of No. 22 S.W.G. sheet brass. .

In making the breather, first cut out a piece of the metal to the dimensions and shape shown in Fig, 2.. In this punch 42 half-inch holes in three rows of 14, then flatten the burrs and bend the metal round an iron bar, soldering it at the seam.

The next task is to cut a circular piece to the dimensions given in Fig. 5, setting off a If-in. edge at right angles to fit the top of the breather at the point A, soldering it. in position.. .

Next cut a rectangular piece of metal to the dimensions given in Fig. 3. Punch a 1-in. hole as. shown • and Lend the metal into a.eircular form, soldering the seam.

The centre cone should be made of No. 28mesh woven-copper wire of the dimensions given. The bottom should be edged to fit the portion C of the breather and soldered into position at B. The narrow strip shown in Fig. 4 should be cut from a piece of No. 18 S.W.G. brass. This should he bent round the barrel of the breather and soldered into position to form a shoulder. Any surplus solder round the collar or shoulder should be filed off in order to let the breather rest evenly on the brass sacket usually fitted to the crankcase. Breathers may be cleaned by immersion in boiling caustic' soda for a few miinutes, washing them thoroughly afterwards to prevent corrosion.