MAKING BEST USE OF• THE FORD.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, Which Will Appeal to the Owner, Driver and Repairer.

IN THIS series of hints concerningthe Ford light chassis and ton truck wherever they are employed for commercial purposes, we endeavour to deal with the subject from every view-point, so that the advice given will appeal to the owner, driver; marntenance engineer, or mechanic. Valuable sources of.information are being tapped for this purpose, and it should be understood that the advice given will be derived from those with an intimate knowledge of ' the subject.

We shall welcome for inclusion among the hints those which have proved of value to individual users, and will make suitable remuneration for any published. What we desire are the results of practice. Readers are recommended to obtain the original " Book of the Ford," which constitutes a complete manual dealing with the Ford car, the van and the truck. 2s. 9d. post free from the offices of this journal.

177.—Preventing Tyre Trouble on Vehicles with Detachable Rims.

During long spells of wet weather considerable tyre trouble often occurs on Ford vans or trucks fitted with detachable rims. Upon removing a tyre or its rim, wet patches may be noticed on the canvas. The moisture which penetrates causes rot to be set up, and the canvas breaking away sometimes pinches the tube as the wheel revolves.

Much of this creeping of water into the rim can be averted. The slot in the wheel is sometimes too large for the valve stem ; the slot in the rim may ° also be oversize. This is where the water penetrates. It is not of much advantage to screw a locknut on to the valve stem, as the water merely gets between the rim and the wheel. It is the-slot in the detachable rim which requires to be made watertight, and this can be done by screwing a stern nut tightly on to the rim before replacing this in the wheel, thus preventing the water from obtaining access.

Should the nut not cover the hole sufficiently a leather washer may be inserted beneath it. Such a washer can easily be made from the piece of leather found inside the cap of a petrol can.

178.—An Experience with the Side Brakes of the Ton Truck.

A little time ago a Ford ton truck was brought into the workshops for the side brakes to be relined. On dismantling the rear road wheels, it was found that the axles and roller hearings were badly worn B42 It was also noted that the bottom brake shoes were worn almost away, whilst the top shoes were hardly touched.

What happened was that, owing to the wear on the axles and bearings, the axle casing dropped and, consequently, the lower shoes had all the wear.

In the particular instance under consideration the vehicle could not be spared very long, and the repairers were obliged to reline the lower bands and to replace the worn bearings, but in an endeavour to help matters the adjustments on the side brakes were let right out. In two days the lorry was again in the shops with all the Ferodo worn off the bottom shoes, which shows that it is practically useless to do anything with the brakes until all wear in the axles and bearings is eliminated. Any other procedure is merely false economy.

179.—An Emergency Support in Case of a Broken Crankcase Arm.

In the untoward event of the arm of the crankcase breaking, the power unit may temporarily be held in place on the chassis by simple means. Take a length of wire rope in. diameter, and procure from somewhere a bar of steel or a baulk of wood sufficiently long to reach from side to side of the frame of the chassis. Lay the bar, or baulk, in the frame and loop the wire over the bar and under the crankcase close to the universal ball joint ; then take the wire, round the bar again, making three or four turns round each. If this be done with the engine jacked up into a position a little higher than normal it will be found, when the jack is removed, that it will settle down into its correct position and that, with this temporary support, it can be run many miles without any danger.

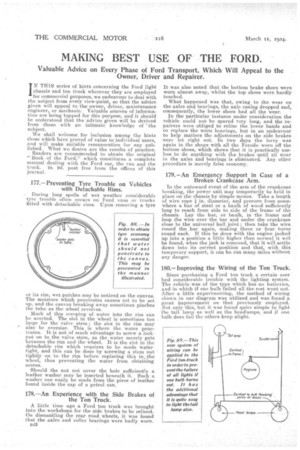

180.—Improving the Wiring of the Ton Truck.

Since purchasing a Ford ton truck a certain user had considerable trouble with the lighting system. The vehicle was of the type which has no batteries, and in which if one bulb failed all the rest went out. After a little experimenting, the method of wiring shown in our diagram was utilized and was found a great improvement on that previously employed. Not only this, but it was found quite simple to light the tail lamp as well as the headlamps, and if one bulb does fail the others keep alight.