SOME RECENT THORNYCROFT IMPROVEMENTS.

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

Details of Small Additions and Modifications Designed to Improve the Efficiency of the Products of this Well-known Company.

JJOWEVER well a chassis may have been designed in the first instance, small modifications often show themselves to be desirable only after the chassis has been in actual employment for a considerable period, and as a result of the, oft-times, rough handling which it receives at the hands of its users. Even in the best-known chassis on the market slight improvements can constantly be made as the result of experience, and this is all to the good as promoting the efficiency of the ultimate design. We are sure that all makers we: come criticism on the part of the purchasers of their vehicles as, in. the vast majority of cases, it is only by the information imparted by such critics that they can obtain the necessary knowledge regarding the wearing qualities of their productions. During a recent visit to the works of John T. Thornycroft and CO., Ltd., at Basingstoke, we observed two or three new points in design which may prove of interest to our readers. For instance, in the frames, particularly those of pas

senger vehicle chassis, it is important that twisting should, so far as possible,

be prevented. Bodies are now being constructed of far lighter types than was formerly the case, and they depend more upon the chassis for their streneth, so far as twisting stresses are concerned, than upon the Wavy timbers which were previously employed as longitudinal bearers.

Now, in the Thornycroft B.T. and J. type chassis; stout cross-braces are employed, their ends being turned over and riveted to the frame side members in such a way that the webs are not re duced in strength. These braces are situated approximately in the middle of the frame, and have proved very valuable in preventing twist.' In future they will be fitted as standard on all models, whether for passenger work or otherwise.

Another improvement, not quite so int • portant, but nevertheless of interest, is the new magneto control used upon the E.T.-type chassis In the old type the control mechanism was anchored on the magneto rocker, and the weight thus im

posed caused the rocker and bearing upon which it moved to wear mBre rapidly. In the new control a forked rocking lever is fulcrumed on a stud fitted into

the crankcase, and held in position by a 'simple split-pin. To one arm of the fork on this lever is connected the rod coming from the magneto control, whilst a short link connects the other arm through the medium of a short doutriecranked link to the magneto, thus removing all weight from the rocker When a vehicle is employed in cold weather, particularly if cola winds are prevalent, a radiator efficient enough to give ample cooling in hot weather sometimes causes the temperature of the water in the jackets of the engine to he so low that the engine is not working at a high enough temperature to enable it to produce its proper power, as it is well known that within certain limits the greater the heat at which an engine works the greater the efficiency both as regards fuel consumption and power produced. Therefore, various expedients are employed either to restrict the-flow of

water through the radiator or to blank

off a portion of the cooling area. In some cases thermostats which bypass some of the cooling water are employed, but these are sometimes awkward to fit in an existing vehicle, and have not always proved reliable in long periods of service.

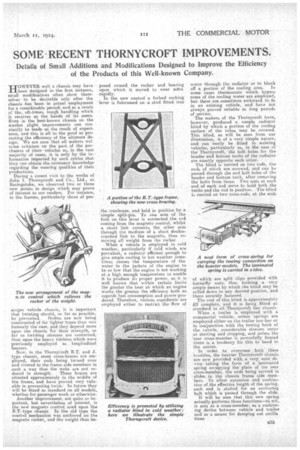

The makers of the Thornycroft have, however, produced a simple radiator blind by which a portion of the cooling surface of the tubes may be covered. This blind, as will be seen from our illustration, is of a very simple nature, and can easily be fitted in existing vehicles, particularly as, in the case of the Thornycroft, the bolt holes for the header and bottom tanks of the radiator are exactly opposite each other.

The blind is carried on two rods, the ends of which are screwed, and can be passed through the end bolt holes of the header and bottom tank, after removing the bolts from these. Two nuts at each end of each rod serve to hold both the tanks and the rod in position. The blind is carried on two cross-rods, at the ends of which are split clips provided with butterfly nuts, thus forming a very simple means by which the blind may be rolled down to any desired position, and there securely fastened, . The cost of this blind is approximately £2 cpmplete, and it is being fitted as standard to all Thornycroft bus chassis.

When a trailer is employed with a commercial vehicle; unless springs are employed either on the trailer tow-bar or in conjunction with the towing hook of the vehicle, considerable stresses occur at starting and stopping, and unless the rear cross-member is powerfully braced there is a tendency for this to bend in the centre.

In order to overcome both these troubles, the heavier Thornycroft chassis are now provided with a very neat device taking the form of a laminated spring _occupying the place of the rear cross-member, the ends being carried in slides in the chassis frame side members. To allow extension and contraction of the effective length of the spring, each end is slotted for an anchoring bolt which is passed through the slide. It will be seen that this new spring actually performs three functions—to wit, it acts as a cross-member, as a cushioning device between vehicle and trailer and as a means for damping out oscilla tions