Sachs-Boge fights rock 'n' roll

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

I/ Two new suspension developments from Sachs-Boge spotlight the kind of ride and handling that drivers of tomorrow's trucks could soon be enjoying.

Automatic Damping Control (ADC) is designed to reduce damage to truck cargoes and road surfaces, as well as reducing tyre wear and body roll. It automatically selects soft, medium or hard damper settings according to information received from on-board sensors.

Controllable damper

In place of the normal telescopic shock absorbers a controllable damper is fitted which is similar to a conventional damper but has either externally mounted control valves or internal valves and electric pumping equipment. Damping fluid is pumped in or out of the damper to provide the required setting.

The system is said to react to sensor inputs in around 20-30 milliseconds. Sensors detect steering angle, road speed, body and vertical axle acceleration, brake applications and pressure, and vehicle acceleration. Roll movements can be monitored through pressure sensors in the air suspension bellows.

Body roll

Active Roll Stabilisation (ARS) reduces body roll, particularly with high centre of gravity loads. The system is based on a conventional anti-roll bar, split in the middle, with the two halves linked by a hydraulic motor which can apply torque to the bar to counteract body roll. Sensors measure steering angle and road speed and feed the information to a control unit. During cornering the control unit opens two proportional flow valves which control the torque produced by the anti-roll bar motors. Hydraulic pressure to operate the motors is provided by an engine-driven pump which takes about 4kW of engine power; roughly the same as a power steering system.

Safety margin

Such comparatively low power limits the active anti-roll characteristics, but Sachs-Boge claims that this provides ARS with a safety margin, warning the driver when cornering limits are reached (see graph below).

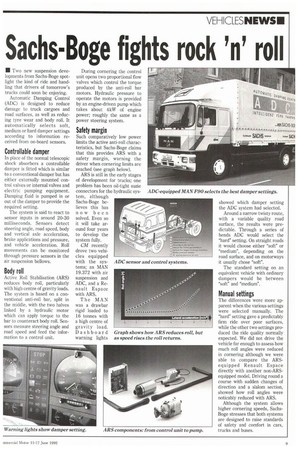

CM recently drove two vehicles equipped with the systems; an MAN 19.372 with air suspension and ADC, and a Renault Espace with ARS.

The MAN was a drawbar rigid loaded to 16 tonnes with a high centre of gravity load. Dashboard warning ights showed which damper setting the ADC system had selected.

Around a narrow twisty route, with a variable quality road surface, the results were predictable. Through a series of bends ADC would select the hard" setting. On straight roads it would choose either "soft" or "medium", depending on the road surface, and on motorways it usually chose "soft".

The standard setting on an equivalent vehicle with ordinary dampers would be between "soft" and "medium".

Manual settings

The differences were more apparent when the various settings were selected manually. The "hard" setting gave a predictably firm ride over poor surfaces, while the other two settings produced the ride quality normally expected. We did not drive the vehicle far enough to assess how much roll angles were reduced in cornering although we were able to compare the ARSequipped Renault Espace directly with another non-ARSequipped model. Driving round a course with sudden changes of direction and a slalom section, showed how roll angles were noticably reduced with ARS.

Although the system allows higher cornering speeds, SachsBoge stresses that both systems are designed to raise standards of safety and comfort in cars, trucks and buses.