IT'S BIG ON THE STREETS

Page 31

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

The Mercedes-Benz 811D is a 7.5-tonne oad carrier with the • racticalit of a van. Does the result make sense on cit streets?

MI Mercedes-Benz builds two ranges of 7.5-tonners: the LN features the conventional forward control chassis with a 'heavy truck' design, while the lighter T2 family, available both as a chassis cab and with an integral body, aligns itself more with the style of the panel van.

Common components are used in certain areas, such as the rear of the cab and in the roof, while the windscreen is the same in both ranges as are some of the door parts.

The integral T2 7.5-tonner is aimed at multi-drop urban distribution operations.

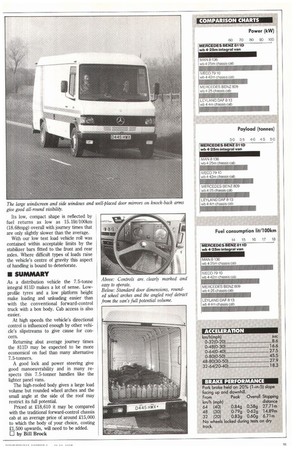

The turbocharged 0M364A diesel engine, rated at 85kW (114hp) at 2,600rpm is used in naturally-aspirated guise to power the lighter 709D and 609D series. Turbocharging not only adds 29% in power output but also raises peak torque from 266Nm (196Ibft) at 1,400rpm to a more healthy 380Nm (280Ibft) at 1,500rpm.

The turbocharged four-cylinder engine was introduced with the 7.5-tonne integral van last July (the Dusseldorf integral van was previously only available up to 6.5 tonnes). The turbocharged 0M364A unit extends no further back into the cab's floor space than the naturally-aspirated engine.

Limited space means that MercedesBenz's even more powerful but longer naturally-aspirated 0M366 six-cylinder engine would not fit.

• BODYWORK

With the longer 4.25m-wheelbase option and a high roof as standard, the van body has a huge 17.4m3 capacity.

Its low 0.82m floor height means that the floor area is reduced by the rounded rear wheelarches which give ample clear ance for the 205/75R low-profile tyres but provide an unsuitable base on which to stack boxes. A standard protruding rear step eases entry at the rear.

Mercedes-Benz has dropped the conventional spot-weld method of construction, which has been blamed as a starting point for body corrosion. Instead the van's outer skin is bonded to the frame using epoxy resin.

The rear doors are not extended to complement the extra height afforded by the high roof, but as an option they open through 270* to fasten alongside the bodywork if needed.

Vertical flat side panels make the most of the interior volume and sliding doors can be fitted on either side to give access to the front of the load platform.

A full-height steel bulkhead behind the driving compartment provides the necessary degree of load restraint, but tapered sides to the roof may restrict full use of the internal height.

• CAB COMFORT

The cab's step well, situated behind the front axle and inside the door, stays clean and dry, but with the door closed it becomes a natural trap for anything that falls on the floor.

Rubber floor covering is easy to keep clean and cross-cab access is good once past the steering wheel, thanks to the low engine cover which does restrict leg room with the optional twin passenger seat.

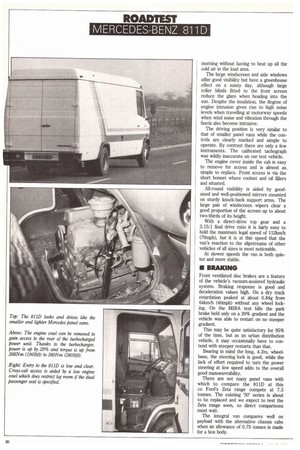

Some 35kg of insulating material deadens noise and also contains heat. Some of the insulation is fitted to the cab's rear panel and as a result the heater warms the cab area quickly on the coldest morning without having to heat up all the cold air in the load area.

The large windscreen and side windows offer good visibility but have a greenhouse effect on a sunny day, although large roller blinds fitted to the front screen reduce the glare when heading into the sun. Despite the insulation, the degree of engine intrusion gives rise to high noise levels when travelling at motorway speeds when wind noise and vibration through the fascia also become intrusive.

The driving position is very similar to that of smaller panel vans while the controls are clearly marked and simple to operate. By contrast there are only a few instruments. The calibrated tachograph was wildly inaccurate on our test vehicle.

The engine cover inside the cab is easy to remove for access and is almost as. simple to replace. Front access is via the short bonnet where coolant and oil fillers and situated.

All-round visibility is aided by goodsized and well-positioned mirrors mounted on sturdy knock-back support arms. The large pair of windscreen wipers clear a good proportion of the screen up to about two-thirds of its height.

With a direct-drive top gear and a 3.15:1 final drive ratio it is fairly easy to hold the maximum legal speed of 1121undi (70mph), but it is at this speed that the van's reaction to the slipstreams of other vehicles of all sizes is most noticeable.

At slower speeds the van is both quieter and more stable.

• BRAKING

Front ventilated disc brakes are a feature of the vehicle's vacuum-assisted hydraulic system. Braking response is good and deceleration values high. On a dry track retardation peaked at about 0.84g from 64Imi/h (40mph) without any wheel locking. On the MIRA test hills the park brake held only on a 20% gradient and the vehicle was able to restart on no steeper gradient.

This may be quite satisfactory for 95% of the time, but as an urban distribution vehicle, it may occasionally have to contend with steeper restarts than that.

Bearing in mind the long, 4.2m, wheelbase, the steering lock is good, while the lack of effort required to turn the power steering at low speed adds to the overall good manoeuvrability.

There are not many panel vans with which to compare the 811D at this co Ford's Zeta range compete at 7.5 tonnes. The existing '50' series is about to be replaced and we expect to test the Zeta range soon, so direct comparisons must wait.

The integral van compares well on payload with the alternative chassis cabs when an allowance of 0.75 tonnes is made for a box body. Its low, compact shape is reflected by fuel returns as low as 15.11it/100km (18.68mpg) overall with journey times that are only slightly slower than the average.

With our low test load vehicle roll was contained within acceptable limits by the stabilizer bars fitted to the front and rear axles. Where difficult types of loads raise the vehicle's centre of gravity this aspect of handling is bound to deteriorate.

II SUMMARY

As a distribution vehicle the 7.5-tonne integral 811D makes a lot of sense. Lowprofile tyres and a low platform height make loading and unloading easier than with the conventional forward-control truck with a box body. Cab access is also easier.

At high speeds the vehicle's directional control is influenced enough by other vehicle's slipstreams to give cause for concern.

Returning abut average journey times the 811D may be expected to be more economical on fuel than many alternative 7. 5-tonners.

A good lock and power steering give good manoeuvrability and in many respects this 7.5-tanner handles like the lighter panel vans.

The high-roofed body gives a large load volume but rounded wheel arches and the small angle at the side of the roof may restrict its full potential.

Priced at £18,610 it may be compared with the traditional forward-control chassis cab at an average price of around £15,000. to which the body of your choice, costing £1,500 upwards, will need to be added.