A FORWARD-CONTROL CHASSIS

Page 58

Page 59

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

for Double-saloon Bodies

TT has already been proved that an important market exists amongst municipal

and private operators for four-wheeled buses .seating approximately 50 passengers. Hitherto Guy Motors, Ltd., Fallings Park, Wolverhampton, has confined its activities in this direction to its well-known rigid-frame six-wheeler, and although this type of vehicle is giving great satisfaction in many parts of the country, not all users are convinced that it is necessary to employ six wheels on any but the largest buses.. We do not propose here to enter into a controversy with reference to this matter and as to how it will be regarded in the future. It is sufficient that there is business to be done at present with each type, and Guy Motors, Ltd„ has very wisely decided to cater for both markets. We say wisely, advisedly, after having carefully inspected and had a short test run on this latest product from the Wolverhampton works.

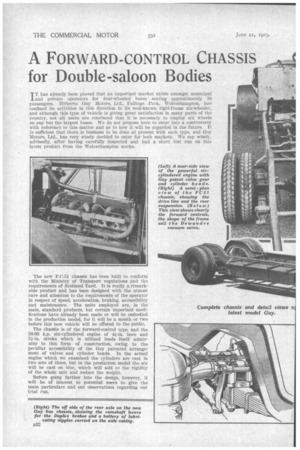

The new F.C.51 chassis has been built to conform with the Ministry of Transport regulations and the requirements of Scotland Yard. It is really a remarkable product and has been designed with the utmost 'care and attention to the requirements of the operator in respect of speed, acceleration, braking, accessibility and maintenance. The units employed are, in the main, standard products, but certain important modifications have already been made or will be embodied in the production model, for it will be a month or two before this new vehicle will be offered to the public.

The chassis is of the forward-control type, and the 58-96 h.p. six-cyliudered engine of 44-in. bore and 5i-in. stroke which is utilized lends itself admirably to this form of construction, owing to the peculiar accessibility of the Guy patented arrangement of valves and cylinder heads. In the actual engine which we examined the cylinders are cast irk two sets of three, but in the production model the six will be cast en bloc, which will add to the rigidity of the whole unit and reduce the weight.

Before going farther into the design, however, it will be of interest to potential users to give the main particulars and our observations regarding our trial run,

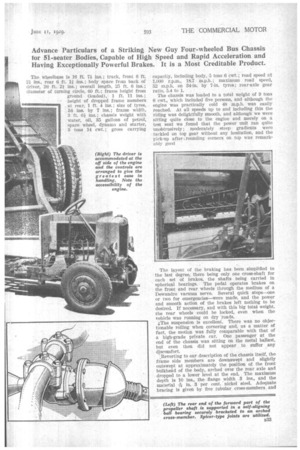

The wheelbase is 16 ft. 7i ins.; track, front 6 ft. 21 ins., rear 6 ft. 1g ins.; body space from back of driver, 20 ft.. 21 ins.; overall length, 25 ft. 6 ins.; diameter of turning circle, 60 ft.; frame height from ground (loaded), 1 ft. 11 ins.; height of dropped frame members at rear, 1 ft. 4 ins.; size of tyres, 34 ins. by 7 ins.; frame width, 3 ft. 61 ins.; chassis weight with water, oil, 35 gallons of petrol, spare wheel, dynamo and starter, 3 tons 14 cwt.; gross carrying capacity, including bo,dy,-5 tons 6 cwt.; road speed at 1,000 r.p.m., 18.7 M.p.h.; maximum road speed, 52 m.p.h. on 34-in. by 7-in. tyres; rear-axle gear ratio, 5.4 to 1. • The chassis was loaded to a total weight of 9 tons 6 cwt., which included five persons, and although the engine was practically cold 48 m.p.h. was easily reached. At all speeds up to and including this the riding was delightfully smooth, and although we were sitting quite close to the engine and merely on a. test seat we found that the power unit ran quite unobtrusively; moderately steep gradients were tackled on top gear without any hesitation, and the pick-up after rounding corners on top was remarkably good The layout of the braking has been simplified Lo the last degree, there being only one cross-shaft for each set of brakes, the shafts being carried in spherical bearings. The pedal operates brakes on the front and rear wheels through the medium of a Dewandre vacuum servo. Several quick stops—one or two for emergencies—were made, and the power and smooth action of the brakes left nothing to be desired. If necessary, and with this big total weight, the rear wheels could be locked, even when the vehicle was running on dry 'roads.

AThe suspension is excellent. There was no objectionable rolling when cornering and, as a matter of fact, the motion was fully comparable with that of a high-grade private car. One passenger at the end of the chassis was sitting on the metal ballast, but even then did not appear to suffer any discomfort.

Reverting to our description of the chassis itself, the frame side members are downswept and slightly outswept at approximately the position of the front bulkhead of the body, arched over the rear axle and dropped to a lower level at the end. The maximum depth is 10 ins., the flange width 3 ins., and the material -156 in. 3 per cent. nickel steel. Adequate bracing is given by five tubular cross-members. and

a drop-curved channel-section member at the front; two of the former connect the rear-spring brackets.

An important point in the design is that the Tecalemit grease-gun lubricators are arranged in conveniently situated batteries, two sets of four on the rear axle, a set of seven on a cross-member, six on a plate at the near side of the sub-frame between the clutch and gearbox, and seven on a bracket mounted on the front off-side frame member, all being connected to the various points by small-gauge brass tubes. The only additions to these are the main supplies for the engine, gearbox and rear axle, a lubricator on the clutch withdrawal and another on the rear universal joint. It must be remembered that, as with other Guy chassis, oil is utilized throughout.

Engine and gearbox are carried upon a sub-frame mounted at three points in the manner with which all users of Guy vehicles are familiar. It absolutely insulates these important units from all stresses which might otherwise be inflicted by twisting of the mein frame, whilst another advantage of the construction is that in the event of the main frame becoming damaged the sub-franvi with its units can be supported by jacks and the main frame lifted clear.

The clutch is a single-plate pattern, the ball-thrust withdrawal gear acting through ball-ended levers, a spring-loaded clutch stop being brought into opera-1 tion if the pedal be depressed beyond a certain distance. There is a three-layer fabric joint on the clutch shaft, and the protecting cover of this forms one member of the clutch brake.

An important feature of the gearbox is that a centre bearing is provided, both for the main shaft and the layshaft, thus preventing whip and, consequently, reducing noise. The ratios are as follow :— Top, 5.4 to 1; third, 9.35 to 1; second, 19.5 to 1; first, 27 to 1; reverse, 25 to 1. The selector mechanism is included within the box, but adjustments to it can be made without opening the box or removing the oil. Inspection is easily afforded by a cover Constituting practically the whole top. Provision is made for driving a speedometer, governor or B34 tyre primp, the take-off being covered by a plate.

Behind the gearbox is a large universal joint of the fork-and-pin type, protected 1?yr an aluminium cover, The propeller shaft is divided, the centre support consisting of a self-aligning ball bearing carried in a stout bracket bolted to a cross-member. The rear portion of the propeller shaft has a plunger joint at the forward end and two Spicer-type joints. At this point it may be mentioned that sheetaluminium undershields arc provided under the flywheel and gearbox and the front end of the engine.

An underneath worm is utilized in the horizontal banjo axle, which has a light pressed-steel cover. The centres of the worm gearing are 8 ins., so that little trouble should occur at this point.

We have already referred to the braking, but may mention, however, that the shoes are 16i ins., in diameter and 4 ins, wide; they are of the Duplex pattern and are faced with t-in. friction material. High-carbon steel is used for the single drums and malleable iron for the shoes, which are protected by dust covers. All the camshaft bushes are lubricated from the batteries of nipples. To avoid oil reaching. the brake drums, special retainers are utilized in the

axle; these have leathers pressing on the differential shafts.

A Dewandre vacuum servo is mounted outside the off-side frame member, and care has been taken to keep absolutely in line the operating rods passing to and from it. The spherical bearings for the camshafts of the front-wheel brakes are carried on the top pads of the springs. Grover-type spring washers are utilized on the joints of the brake connections to prevent rattle, and the brake levers are carried on serrations. Adjustment of the rear rods is effected by right and lefthand-threaded turnbuekles, and to prevent whip the rods slide in spring-steel supports.

Excellent braking results have been obtained, the stopping distances being as follow :—From 20 m.p.h., 20 ft. • from 25 m.p.h., 33 ft.; from 30 m.p.h, 36 ft; from :40 m.p.h., 84 ft. This repreSents a deceleration figure averaging something over.20 ft. per sec. per see.

As regards the suspension, the rear springs have 5-ft. centres, are underslung and are 4 ins. wide.

Steering is effected by a gear of the cam and roller type bracketed to the off-side dumbiron.

The petrol tank is mounted outside and alongside the -off-side frame member, although, if desired, it can be fitted at the near side and thus be more readily

accessible for filling from a petrol station at the left of the road. A tap for main and reserve supplies is included. The petrol feed is by Autovac.

High-tensile alloy steel is used for the 11-section front axle, on which the swivel pins are mounted by taper-roller bearings; these are lubricated from oil reservoirs above the swivels.

All the wheels run on adjustable taper-roller bearings.

It is unnecessary for us to give a comprehensive description of the engine, as this so closely resembles the type used on the six-wheeled bus chassis. It will be sufficient to say that it has a seven-bearing crankshaft and an eight-bearing camshaft, whilst the intermediate timing gears are carried on adjustable centres so that silent running can be ensured. The crankcase is stiffly ribbed, and the whole of the drive for camshaft, dynamo, water pump and magneto is obtained by skew gearing, the magneto being mounted at one end of the cross-drive at the front with the water pump at the other. The usual Guy system of pressure feed to the main bearings and low-pressure supply to troughs for the big-ends is employed. Provision is made for preventing an excessive amount of lubricant being supplied to the troughs.

Certain modifications have been made in the exhaust manifold. This is now made in two parts, one of which slides into the other and is provided with a spring piston ring to make a good joint. A blind extension piece on the forward portion is bolted to the inlet manifold to constitute a hot spot. Finally, we may mention that aluminium pistons and aluminium cylinder heads are employed, each of the former having three pressure rings and one acting as an oil scraper.

The equipment and auxiliaries include a Visco air filter, Solex carburetter, Lucas magneto and C.A.V. dynamo. Where a starter is employed, this is also of C.4.17 make, and a good point is that the end of the Bendix-pinion housing is supported by a bracket.