New Products

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

from an

Electric vehicle Factory

WITH the rapid advances which are taking place in the petrolvehicle section of the commercial-motor field the development of the electric vehicle is rather inclined to be overlooked. The usefulness of such marlines, however, for special work cannot be doubted, and for this reason we have made a special point of noting the developments of Electromobile, Ltd., the works of which are at Otley, in Yorkshire.

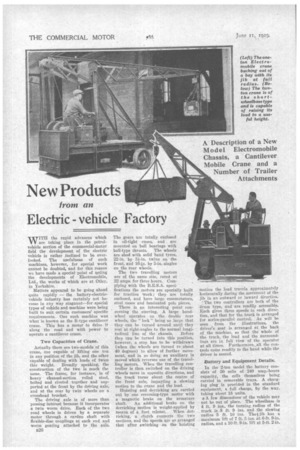

Matters appeared to be going ahead quite rapidly — the battery-electricvehicle industry has certainly not become in any way stagnant—for special types of vehicle and machine were being built to suit certain customers' specific requirements. One such machine was what is known as the It-type cantilever crane. This has a motor to drive it along the road and with power to operate a cantilever crane.

Two Capacities of Crane.

Actually there are two-models of this crane, one capable of lifting one ton in any position of the jib, and the other capable of dealing with loads of twice this weight. Broadly speaking, the construction of the two is much the same. The frame, for instance, is of heavy channel-section rolled steel, bolted and riveted together and supported at the front by the driving axle, and at the rear by twin wheels on a crosshead bracket.

The driving axle is of more than passing interest because it incorporates a twin worm drive. Each of the two road wheels is driven by a separate motor through a cardan shaft with flexible-disc couplings at each end and worm gearing attached to the axle.

B26

The gears are totally enclosed in oil-tight cases, and are mounted on ball bearings with ball-type thrusts. The wheels are shod with solid band tyres, 22-in. by 3i-in. twins on the front, and 16-in. by 5-in, singles on the Tear wheels.

The two travelling motors are of the same size, rated at 22 amps, for three hours. Complying with the B.E.S.A. specifications the motors are specially built for traction work ; they are totally enclosed, and have large commutators, steel cases and laminated pole pieces. There is an interesting point con(tuning the steering. A large handwheel operates on the double rear wheels, the " lock" being so large that they can be turned around until they rest at right-angles to the normal longi tudinal line of the chassis. Before they can be turned into this position, however, a stop has to be withdrawn (when the wheels are turned to about 40 degrees) to allow of further movement, and in so doing an auxiliary is moved which reverses one of the travelling motors. When the travelling controller is then switched on the driving wheels move in opposite directions, and the truck turns about the centre of the front axle, imparting a Mewing motion to the crane and the load.

Hoisting and derrieking are carried out by one reversing-type motor with a magnetic brake on the armature shaft. An additional brake on the derricking motion is weight-applied by means of a foot release. When derricking, a clutch connects the twn motions, and the speeds are .so arranged that after switching • on the hoisting motion the load travels approximately horizontally during the movement of the jib in an outward or inward direction. =.The two controllers are both of the drum type, and are readily accessible. Each gives three speeds in each direction, and that for the truck is arranged for series-parallel control. As will be seen from the illustrations, the driver's seat is arranged at the back of the machine, so that the whole of the truck, the load and the surroundings are in full view of the operator at all times. Furthermore, ,all the controls come readily to the hand while the driver is seated.

Battery and Equipment Details.

In the 2-ton model the battery consists of 50 cells of 240 amp.-hours capacity, the cells themselves being carried in removable trays. A charging plug is provided in the standard equipment, a full charge, by the way, taking about 18 units.

t A few dimensions' of the vehicle may not be out of place. The wheelbase is 4 ft. 9 ins., the turning radius of the truck is 8 ft. 9 ins, and the Mewing radius 5 ft. 10 ins. Thel jib has a maximum lift of 7 ft. 3 ins. at 6-ft. 9-in. radius, and a 10-ft. 9-in, lift at 5-ft. 2-in.

radius. These figures give some idea of the size of the veohiele and its capacity. The actnal speed of the lift is at the rate of 20 ft. per minute, whilst the overall speed for the machine on a level road is approximately df m.p.h. Altogether it is a very interesting type. particularly suited to the duties of loading and unloading bulky goods from railway wagons to lorries, etc.

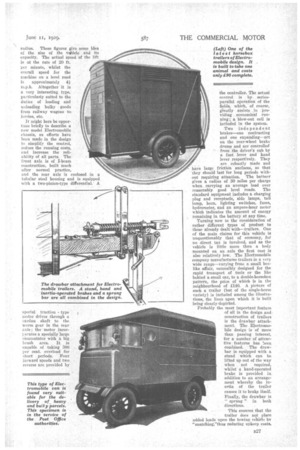

It might here be opportune briefly to describe a new model Electromobile chassis, as efforts have Leon made in the design to simplify the control, reduce the running costs, and increase the reliability of all parts. The frout axle is of I-beam construction, built much after normal practice, and the rear axle is enclosed in a tubular steel housing and is equipped with, a two-pinion-type differential.A

special traction type xliotor drives through a eardan shaft to the worm gear in the rear axle; the motor incorporates a specially large commutator with a big brush area. It is capable of taking 300 Per cent. overload for short periods. Four forward speeds and two reverse are provided by the controller. The actual control is by seriesparallel operation of the fields, which, of course, ghatly assists in Providing economical running; a blow-out coil is included in the system.

Two independent brakes—one contracting and one expanding--act on the rear-wheel brake• drums and are controlled from the driver'S cab by a foot lever and hand lever respectively. They are robustly made and have large friction surfaces, so that they should last for long periods without requiring attention. The battery gives a radius of 30 miles per charge when carrying an average load over reasonably good level roads. The standard equipment includes a charging plug and receptacle, side lamps, tail lamp, horn, lighting switches, fuses, hydrometer, and an ampere-hour metee which indicates the amount of energy remaining in the battery at any time.

Turning now to the consideration of rather different types of product to

• those already dealt with—trailers. One of the main claims for this vehicle is unquestionably that of economy, for no direct tax is involved, and as the vehicle is little more than a body mounted on an axle the first cost is also relatively low. The Electromobile company manufactures trailers in a very wide range—varying from a small boxlike affair, ostensibly designed for the rapid transport of tools or the like behind a small car, to a double-horsebox pattern, the prim of which is in the neighbourhood of 1140. A pictnre of such a trailer (but of the single-horse variety) is included among the illustrations, the lines upon which it is built being clearly 'depicted.

Probably the most important feature of all in the design and construction of trailers is the drawbar attachment. The Electromobile design is of more than passing interest, for a number of attractive features has been combined. The drawbar is equipped with a stand which can be lifted up out of the way when not required, whilst a hand-operated brake is provided in addition to an arrangement whereby the inertia of the trailer causes it to brake itself. Finally, the drawbar is " sprung " in both directions.

This ensures that the trailer does not place added loads upon the towing vehicle by "snatching,"thua reducing upkeep costs.