TI

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

made

ANTIQUES?

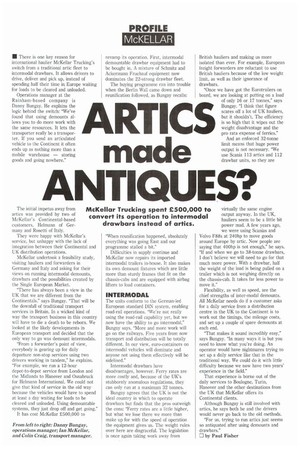

McKellar Trucking spent E500,000 to convert its operation to intermodal drawbars instead of artics.

The initial impetus away from artics was provided by two of McKellar's Continental-based customers, Heimann of Germany and Rosetti of Italy.

They were happy with McKellar's service, but unhappy with the lack of integration between their Continental and UK distribution operations.

McKellar undertook a feasibility study, visiting hauliers and forwarders in Germany and Italy and asking for their views on running intermodal demounts, drawbars and the possibilities created by the Single European Market.

"There has always been a view in the UK that we are different from the Continentals," says Bungay. "That will be the downfall of traditional transport services in Britain. In a wicked kind of way the transport business in this country will have to die a death to be reborn. We looked at the likely developments in European transport and decided that the only way to go was demount intermodals.

"From a forwarder's point of view, everybody is gearing up for daily departure non-stop services using two drivers working in tandem," he explains. "For example, we run a 12-hour depot-to-depot service from London and the Midlands to Hanover and Osnabruck for Heimann International. We could not give that kind of service in the old way because the vehicles would have to spend at least a day waiting for loads to be cleared and unloaded. Using demountable systems, they just drop off and get going.

It has cost McKellar £500,000 to "When reunification happened, absolutely everything was going East and our programme stalled a bit."

Difficulties in supply continue and McKellar now repairs its imported intermodal trailers in-house. It also makes its own demount fixtures which are little more than sturdy frames that fit on the chassis-cabs and are equipped with airbag lifters to load containers.

INTERMODAL

The units conform to the German-led European standard DIN system, enabling road-rail operations. "We're not really using the road-rail capability yet, but we now have the ability to go intermodal," Bungay says. "More and more work will go on the railways. Five years from now transport and distribution will be totally different In our view, euro-containers on intermodal vehicles will dominate and anyone not using them effectively will be sidelined."

Intermodal drawbars have disadvantages, however. Ferry rates are more costly and, because of the UK's stubbornly anomalous regulations, they can only run at a maximum 32 tonnes. Bungay agrees that the UK is not the ideal country in which to operate drawbars but finds that the pros outweigh the cons: "Ferry rates are a little higher, but what we lose there we more than make up for with the speed of operation the equipment gives us. The weight rules over here are disgraceful. The legislation is once again taking work away from virtually the same engine output anyway. In the UK, hauliers seem to be a little bit power mad. A few years ago, we were using Scanias and Volvo F88s at 240hp to move goods around Europe by artic. Now people are saying that 400hp is not enough," he says. "If and when we go to 38-tonne drawbars, I don't believe we will need to go for that much more power. With a drawbar, half the weight of the load is being pulled on a trailer which is not weighing directly on the chassis-cab. It takes far less power to move it."

Flexibility, as well as speed, are the chief strengths of inter-modal demounts. All McKellar needs do if a customer asks for a daily service from a distribution centre in the UK to the Continent is to work out the timings, the mileage costs, and set up a couple of spare demounts at each end.

"That makes it sound incredibly easy," says Bungay. "In many ways it is but you need to know what you're doing. An operator would have nightmares trying to set up a daily service like that in the traditional way. We could do it with little difficulty because we now have two years' experience in the field."

That experience is borne out of the daily services to Boulogne, Turin, Hanover and the other destinations from the UK that McKellar offers its Continental clients.

Although Bungay is still involved with artics, he says both he and the drivers would never go back to the old methods.

"For us, trying to run artics just seems so antiquated after using demounts and drawbars."

El by Paul Fisher