PROFILE

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

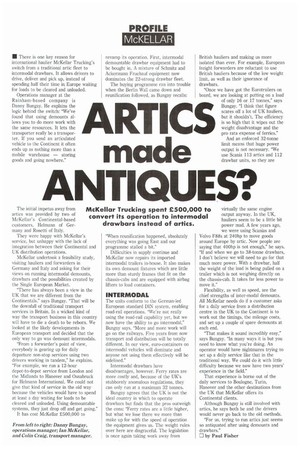

McKELLAR

iii There is one key reason for international haulier McKellar Trucking's switch from a traditional artic fleet to intermodal drawbars. It allows drivers to drive, deliver and pick up, instead of spending half their time in Europe wailing for loads to be cleared and unloaded.

Operations manager at the Rainham-based company is Danny Bungay. He explains the logic behind the switch: "We've found that using demounts allows you to do more work with the same resources. It lets the transporter really be a transporter. If you send an articulated vehicle to the Continent it often ends up as nothing more than a mobile warehouse — storing goods and going nowhere." revamp its operation. First, intermodal demountable drawbar equipment had to be bought in. A mixture of Schmitz and Ackermann Fruehauf equipment now dominates the 22-strong drawbar fleet.

The buying programme ran into trouble when the Berlin Wall came down and reunification followed, as Bungay recalls: British hauliers and making us more isolated than ever. For example, European freight forwarders are reluctant to use British hauliers because of the low weight limit, as well as their ignorance of drawbars.

"Once we have got the Eurotrailers on board, we are looking at putting on a load of only 16 or 17 tonnes," says Bungay. "I think that figure scares off a lot of UK hauliers, but it shouldn't. The efficiency is so high that it wipes out the weight disadvantage and the pro rata expense of ferries."

And an enforced 32-tonne limit means that huge power output is not necessary. "We use Scania 113 artics and 112 drawbar units, so they are