Weighbridging for the record

Page 83

Page 84

If you've noticed an error in this article please click here to report it so we can fix it.

Accurate weighing of incoming and outgoing vehicles on a 50ft weighbridge enables a Midlands canning company to eliminate costly discrepancies in estimating factory throughput and in evaluating individual loads by Paul Brockington

HAVE you ever seen a weighbridge smiling, not with the malicious intent of catching a wrongdoer with an overloaded vehicle and reporting him to the authorities but with the smug knowledge that it does a first-class job for an employer producing high-class foodstuffs and is on good terms with lorry drivers, at least with the vast majority of them?

Well, I did—on the factory premises of Stratford-uponAvon Canners Ltd, Stratfordupon-Avon, And I came away wondering what the all-round benefits might be of accurate weighing for the record if more universally applied, as distinct from a means of avoiding prosecution for overloading.

The weighbridge is an Avery 40.6-tonne (40-ton) machine with a platform length of 15.24m (50ft) and can accommodate the biggest artics. It is virtually a part of the production line and the recorded Information it provides on incoming and outgoing loads in the form of weight, date and time printouts is compared with the weighbills of suppliers' vehicles and with the estimated loads of delivery lorries, weighbridge checks being made of the tare weight of all vehicles. The value of 51kg (lcwt) of finished goods may be as much as £25, and the inaccuracy of double-weighing long vehicles on a short weighbridge would create serious uncertainties and upset record keeping.

If a print-out shows that an outgoing vehicle is carrying a heavier load than that indicated on the estimate by more than a small margin, an appropriate part of the load is removed and the cause of overweight is investigated before the lorry is allowed to leave, whether the vehicle is operated by a sub-contractor or by the Yeast and Food Division of the Distillers' company of which SonA Canners is a member unit. And a satisfactory explanation has also to be found for any case of underloading.

While these practices ensure that the gvw of the vehicle does not exceed the maximum allowed by the regulations this is rarely a problem, the essential value of programmed weighing being that it shows up discrepancies in good time, which would be impossible to rectify at a later date or would result in an irrecoverable loss.

Apart from sacked peas and haricot beans carried in containers, carrots and beetroot in belt-conveyor vehicles and bulk liquids in tankers, a major proportion of the incoming raw materials and all the out going loads are transported on lm square timber pallets, or in the case of some raw materials in special bins designed for fork-lifting. A typical pallet load is about 0.75 tons.

Of the 23 fork-lift trucks employed by SonA Canners four are normally engaged in unloading raw materials from suppliers' vehicles, seven in loading delivery vehicles and the remainder in servicing the food-processing lines of the factory. Built some four years ago the factory is the main production unit of a complex which includes an older works on the other side of a railway and three warehouses having a total area of 10,74Isqm (116,000sqft) a tunnel under the railway between the two sites providing for pallet movements on trucks hauled by a tug.

An intention to extend the application of fork-lift trucks in the factory and for vehicle

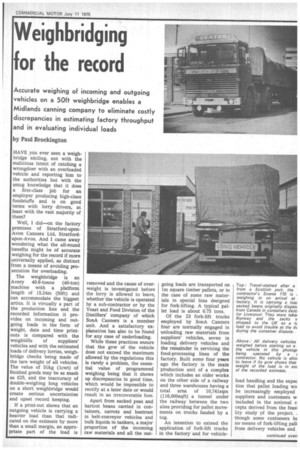

Top: Travel-stained after a from a Scottish port, the contractor's Scania 110 is weighing in on arrival at factory. It is carrying a boat sacked beans originally dispatc from Canada in containers dest) for Liverpool. They were take) Norway and the sacks v shipped to the UK as a It load to avoid trouble at the dc during the container dispute.

Above : All delivery vehicles weighed before starting on a the vehicle in this photogr being operated by a t contractor. No vehicle is altos to leave if its gvw shows that weight of the load is in exc of the recorded estimate.

load handling and the expec tion that pallet loading wo be increasingly employed suppliers and customers w included in the notional c, cepts derived from the feasi lity study of the project. . though some customers ht no means of fork-lifting pall, from delivery vehicles and h the need manually to d the contents of vehicleted containers on to palnay also be a permanent em, exploiting the potenierits of fork-lift trucks to ill is regarded as the only of reducing wasteful ling to a minimum. letisation enables loads riished goods to be prenbled in units, which elimiI manhandling of cases, this is a big advantage in 3 of labour utilization and .dination of the work Sugar and fruit pulp are transported to the factory ankers, which simplifies ling, and the delivery of in bulk for the water !fling plant is also a timelabour-saving facility. The ;fer of sacked or boxed Tials from a vehiclerited container is made by the provision of a ial ramp which enables the :c to move up to the load. le payload penalty of using As is about 10 per cent, while the overall cost of A investment, recovery repair is considerable it is mall proportion of the icial gain derived from palloading.

11 finished goods are carin vehicles operated by division or by sub-contors, and deliveries cover entire country from the th East and West to Scott, loads of raw materials coming from America, Canada and other overseas countries as well as the UK. Loads of empty cans are dispatched to the factory in curtain-sided vehicles.

While platform vehicles will, it is anticipated, continue to be the preferred type of subcontractors (carrying finished goods) rigid and articulated box vans with twin Joloda tracks are available from the division's fleet. Vans have the advantage that sheeting time is eliminated but pallets have to be loaded in strict routedelivery order and this may create difficulties on long-distance runs with multiple drops. Of pertinent general interest with regard to palletisation, a number of the company's customers would not, it is said, know how to handle goods loaded in any other way or be prepared to do it.