Transport tailored to suit

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

Specialising in clothing transport, where delivery periods are short and unit costs are tightly controlled, a haulage company has obtained the services of a former own-account transport man

THE PROVISION of special transport for one commodity or product has certain attractions but it also involves great risks.

Carrying one type of traffic can bring economies in the use of standard equipment, compatibility of loads, concentration of expertise into one method of transport and so on. However, lack of business flexibility, especially when special-purpose vehicles which cannot be used for other traffic must be provided, renders the speoialist operator vulnerable to fluctuations in trading within a particular manufacturing field. In other words, he could founder even though the rest of the transport community is enjoying a period of prosperity.

The risks inherent in specialist transport can be minimised by the use of vehicles which can be used for a variety of purposes and, perhaps the best insurance of an, by being first in the field.

In providing a transport service for unwrapped hanging garments, the haulage company of Tibbett and Britten has been fortunate on both counts. Until recently, there was no other organisation pro

Out of the c and d vehicles to wheeled rails for perami tion to the trunk vehicles is speedy transport system dev for reliable delivery at r outlet.

viding a similar service a outwardly art least, there no difference in the appeara of its vehicles from those c coventional general frei haulier.

Startling growth

The reward of initiative been a startling five-y growth from a small comp employing fewer than 60 s to an organisation associa with Dutch Railways and S Ltd with a national networli nine depots using some vehicles and employing nes 600 people.

Moving clothing the T I B way has a number of ach tages. There is a considers saving on packaging, the k ments arriving at their desti tion uncreased and ready be displayed at the point sale and, a vital factor in hi fashion marketing, handling minimised and expedited that delivery time is reduc The need of the clothing dustry for such a transp service is demonstrated by rapid growth of the compa which itself has brought pr lems. In addition, competit has appeared, notably Natio Carriers' Fashionflow, to courage Tibbett and Britten review its objectives and ;teps to maintain the high ard of reliable service not ifficult to set when small difficult to preserve gh rapid growth.

a first step towards ving its new objectives, )mpany has been success tempting Bob Beckham ike the change from owndirt operation with RHM ; Ltd to haulage with Tiband Britten. Mr Beckham over as chief executive e beginning of this year already plans are taking : to preserve the standard ervice previously estab1.

knowledging that to move one side of the industry e other is fairly unusual, Beckham stresses the arity between the transof food and high-value enable clothing.

; costs

both cases the accent Id be on reliability and I of delivery though this not cause the operator se sight of the importance tit transport costs, for both :ets are extremely cornive. Thus, though the pros are different, the transtechniques required to put on sale are similar. ould be surprising, thereif some of the innovations g considered to solve the ring pains encountered by id B did not include such isticated management and ating techniques as cornrisation and automated :house handling systems. ; far as staff is concerned, objective has been defined closer customer relationand an utterly profesal approach to the job. To .n this, an intensive staff ring scheme has been deed. These innovation's have to be related to the operation of a national network of depots and an interdepot transfer system involving about 35 regularly scheduled night trunks serviced by daily collection and delivery rounds.

For the trunk operation, 34 maximum capacity tractive units are used hauling about 60 40ft box trailers. The tractive units have a high power/ weight ratio so that a reliable high-speed service can be maintained.

This policy has also resulted in an improved fuel consumption and reduced maintenance costs, both factors which help to control total operating costs and, therefore, unit costs in a fleet which is expected to achieve 640,000km (400,000 miles) this year.

The shorter hauls involve the classic articulated operation in which a loaded trailer is dropped at one destination while the tractive unit returns to base with a different loaded trailer. The longer hauls, however, are accomplished by using the " staging " principle in which drivers exchange vehicles at predetermined points en route. It is expected that the advent of EEC drivers' hours regulations will encourage the further use of this method.

In association with other haulage companies on the Continent including Scandinavia, the company is able to maintain a fast, reliable delivery service for imported clothing.

Typical of this service is the transport of clothing from Finland for a well-known chain store network in the UK.

The traffic is collected by an associate company in Finland on Wednesday and shipped to this country arriving by the following Saturday. During the weekend, Tibbett and Britten receive a computer compiled delivery schedule which is executed and clothing loaded ready for distribution beginning on Monday. By the following Wednesday, delivery has been completed nationwide. In all, a one-week delivery service from the origination of the traffic to final retail outlet.

Control office

Ultimate delivery is by means of the c and d fleet of some 240 rigid boxvans of varying sizes. The drivers of these vehicles have been imbued with the importance of keeping regularly in touch with the control office and, at present, telephone in at frequent intervals. Under investigation is the installation of radio control so that the c and d function can be further speeded up.

Improved and redesigned interior body layouts and equipment are also being examined in a further attempt to improve efficiency and the possible use of swop bodies is under consideration.

The nine depots which make, up the Tibbett and Britten network are also high-security clothing warehouses — for fashion garments are an extremely vulnerable traffic.

At these depots, collection and delivery activities continue throughout the day with vehicles which have delivered traffic on the outward leg collecting traffic for the night trunk on the return journey.

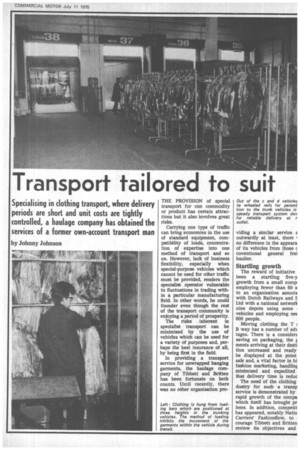

For transport in the c and d vehicles, clothing is suspended on " sets " which comprise a short length of rail about 25cm long with a handle at each end. Each set is capable of holding eight to 10 suits or about 24 summer dresses and the sets themselves are hung from the loading bars in the vehicle.

The customer is charged on the number of sets carried. At the depot, the sets are taken from the vehicle and hung on wheeled rails which are then perambulated to the appropriate trunk vehicle.

The trunk vehicle has loading bars at three heights across the body. The order of loading is interesting because unless the sequence is top rail first, then the bottom rail and lastly the middle rail, difficulty is experienced in filling the rails properly to ensure that the movement of the traffic is restricted within the vehicle during transit.

While the present manual method of handling is common to all the company's depots and though a previous experiment with mechanisation was disappointing, it is intended that a degree of mechanical handling will be introduced during this year.