STANDARD TEST• PROCEDURE Reduces Manufacturing Costs

Page 44

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

ROAD tests of commercial vehicles are frequently reported in "The Commercial Motor," and they . are of great interest and value, not only to operators and intending purchasers, but to manufacturers, as a means for getting some idea of "what the other fellow is doing."

Whilst it is known that Press representatives always make these tests • with a high degree of care and strict accuracy,. local and geographical conditions differ so much that the comparative value of the results cannot always be assessed. For example, some fuel-consumption tests are taken on a relatively level main road, whilst others are logged over an undulating, or even hilly, route. Again, hill-climbs are described and recorded, but because of local conditions, gradients differ, depending on the hills available in the neighbourhood of the manufacturer's works.

The manufacturer can, however, eliminate these differences in setting up a routine for testing chassis, selecting suitable routes and conditions to obtain comparativeresults for proving the performance of any vehicle. It will be realized that testing can represent a high proportion of the cost in the development of any new chassis, or even in proving any major alteration in design. The testing of the chassis or parts is, of course, necessary before production can be planned, or commitments undertaken in the provision of manufacturing equipment. Tests must be extensive to prove reliability, 434 and accurate to obtain data for reference and comparison purposes.

Every precaution has to be taken to try all the parts in the assembly before releasing for production, to avoid modifications after manufacture has begun, and, still more important, to prevent the development of any weakness or defect in service after delivery.

Road tests are conducted during the development of new types or major alterations to existing models, and during production to see that a standard is maintained, and that the chassis is run-in arid mechanically sound. A commercial vehicle, unlike a private car, is an investment and must, therefore, be capable of earning a profit for its owner without the restrictions of, the running-in period at much reduced speeds, which is almost always associated with the private .ear. It is obvious, therefore, that the tests in the " development " category will have to be planned to ensure a satisfactory road performance.

Tests during normal production can be based on the type test, reduced to a safe economical limit to ensure that the performance is maintained and that the parts have beets correctly made and assembled.

The performance of the power unit can be determined by bench tests, where apparatus and instruments are available to enable output and fuel consumptions to be calibrated, giving comparative and reliable -data. Duration tests over long periods at full power can be carried out to prove the engine mechanically, analysis made for heat balance, and, in the case of petrol engines, carburation and part-load consumptions studiedand adjusted. Under equally favourable conditions, cooling tests can be made to forecast radiator and fan assemblies.

In the case of road tests, one has to measure the overall value of the chassis performance and, to collect accurate and comparative data, tests must be arranged to eliminate as much as possible the variables, such as road conditions and the human element.. For that purpose, therefore, Thornycroft tests have been arranged over defined routes under set conditions, the results being recorded by the use of charts for reference and quick analysis.

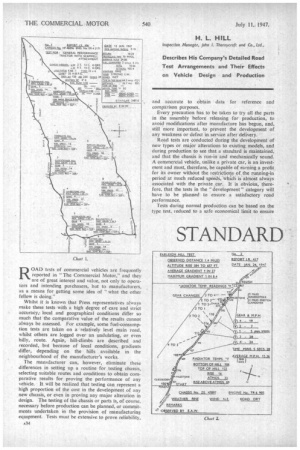

With regard to tests of new-type chassis and major modifications, it can be assumed that tests of the power unit have been completed to arrive at what is considered a satisfactory standard, and the engine set up to forecast the road performance. After installing the unit in the chassis, road tests proceed. The first opera-' lions are to adjust and run-in the complete-chassis fully laden, to ensure that it is safe and roadworthy. All trials are, of course, carried out with test loads to make the laden weights correct, and, in some cases, overloads are arranged, In connection with fuel consumption and general performance, a triangular route is used on roads of mixed character, on which are several hills of various gradients, the total distance being 28 miles. This is shown on chart 1, on which 10 hills are used for recording definite readings. Each hill is approached at 30 m.p.h. and the climb is completed at full power, the gear used and the minimum speed being recorded from the speedometer, already checked for accuracy.

The running time taken to complete the course is recorded and the average speed determined, and by means of a suitable tank the fuel used can be accurately measured and the consumption computed. The gross ton-mpg. (G.T.M.G.) and gross ton-m.p.g. per hour (G.T.M.G.-hr.) can also be compiled, both being useful for comparative purposes. The gross ton-m.p.g. takes into account the average speed and, therefore, gives a more complete assessment of the performance. The time, and distance in top gear are both recorded, and these figures have been found of considerable valuein analysing the overall performance.

The chart showp has been completed to represent a typical test. It should be realized that the conditions of this test are more severe than in normal service, and fuel-consumption figures on this course are at least 10 per cent, lower in value than those obtained in normal operation. For example, the fuel consumption shown of 11.2 m.p g. could be improved to approximately 12.5 m.p.g. under more favourable road conditions.

Timed 11111-climbs

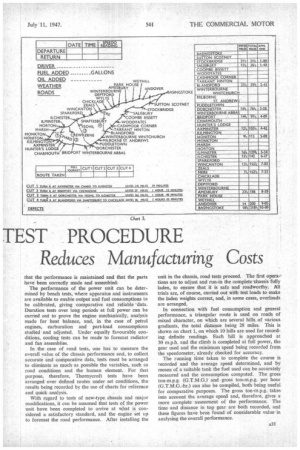

The hill-climbing and cooling tests are made on a conveniently situated hill, and although not particularly steep, the ascent covers a distance of 1.4 miles. The hill has been accurately surveyed and conforms with the details given in chart 2. The timed climb is made from a standing start over a distance of 1.4 miles, from which the average speed can be calculated. The gears used and road speeds attained are recorded at definite observed points on the climb, and on the left-hand side of the chart the positions at which the gear changes are made are indicated by arrows.

Dwing this test radiator temperatures are taken by distance-reading thermometers, the figures being recorded to determine the rise up the hill, and can, if necessary, be plotted to see whether terminal temperatures are reached. Chart 2 shows readings of a typical test.

Brakes are tested under normal service conditions, a suitable level road being used, and measured distances and meter readings recorded. To check the braking system for extended applications, such as when descending long, steep gradients, a test has been devised by using the hill shown on chart 2. The test is severe, but has proved extremely valuable and reliable. The hill is descended in top gear with the engine at full power and the speed controlled to 20 m.p.h. by the application of the brake. At the finish of the. descent, a set amount of travel must remain in the system, and a satisfactory retardation obtained. Drum temperatures are checked to see that these are not excessive, and that correct balance of braking effort is being obtained. •

Acceleration tests are made by the usual methods, records being taken passing through the gears, and from 10 m.p.h. in top gear. The test for hill-climbing, previously described, is a measure of acceleration, as the vehicle is timed from a standing start.

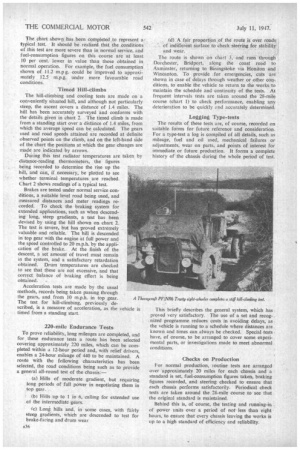

220-mile Endurance Tests To prove reliability, long mileages are completed, and for . these endurance tests a route has been selected covering approximately 220 miles, which can be completed within a 12-hour period and, with relief drivers, enables a 24-hour mileage of 440 to be maintained. A route with the following characteristics has been selected, the road conditions being such as to provide a general all-round test of the chassis:—

(a) Hills of moderate gradient, but requiring long periods of full power in negotiating them in ,top gem.

!. .(b) Hills up to 1 in 6, calling for extended use • of the intermediate ,gears.

(c) Long hills and, in some cases, with fairly steep gradients, which are descended totest for brake-facing and drum wear

(d) A fair proportion of the route is over roads, of indifferent surface to check steering for stability' . and wear.

The route is shown on chart 3, and runs through Dorchester, Bridport, along the coast road to Axminster, returning to Basingstoke via Honiton and Wincanton. To provide for emergencies, cuts are shown in case of delays through weather or other conditions, to enable the vehicle to return to the works to maintain the schedule and continuity of the tests. At frequent intervals tests are taken around the 28-mile

• course (chart 1) to check performance, enabling any deterioration to be quickly nd accurately deterniined.

Logging Type-tests

The results of these tests are, of course, recorded on suitable forms for future reference and consideration. For a type-test a log is compiled of all details, such as mileage, fuel and oil used, mechanical failures or adjustments, wear on parts, and points of interest for immediate or future production. It forms a complete history of the chassis during the whole period of test.

This briefly describes the general system, which has proved very satisfactory. The use of a set and recognized programme reduces costs in avoiding delays, as the vehicle is running to a schedule where distances are known and times can always be checked. Special tests have, of course, to be arranged to cover some experimental parts, or investigations made to meet abnormal conditions.

• Checks on Production

For normal production, toutine tests are arranged over 'approximately 20 miles for each chassis and a standard is set, fuel-consumption figures taken, braking figures recorded, and steering checked to ensure that each chassis performs satisfactorily. Periodical check tests are taken around the 28-mile course to see that the original standard is maintained.

Behind this is, of course, the testing and running-in of power units over a period of not less than eight hours, to ensure that every chassis leaving the works is up to a high standard of efficiency and reliability.