FUEL'S ON THE BILL

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

Controlling fuel costs is an essential aspect of efficient operation, but before you can reduce fuel consumption you have to measure it accurately.

• The dramatic fuel price increases of the 1970s had at least one benefit: they encouraged engine manufacturers to channel research towards improvements in specific fuel consumption.

More recently, environmental concerns — backed up by a stream of emission regulations — have diverted designers' efforts towards reducing pollution levels. Obviously, the less fuel you burn, the less exhaust gases you have to worry about. But with the likelihood of in-service exhaust tests in the near future, emission controls will remain paramount in the minds of the manufacturers.

Truck operators, no matter how Green their views, have to put running costs at the top of the agenda if they intend to survive in an ever more competitive market. They will have to keep a close eye on controlling emission levels as the rules tighten up, but controlling running costs will remain the name of the game, and that means drivers' pay and fuel.

To the surprise of some companies, the two are often related, A proficient driver can command a high rate of pay, but can also save fuel through his skill at the wheel. Several manufacturers organise HGV driving tuition with fuel economy as the prime objective.

Some major operators use fuelconsumption-based driver bonus schemes to reward and encourage fuel-efficient driving techniques.

INCENTIVE SCHEME

For this sort of incentive scheme to succeed, fuel usage needs to be measured more accurately than is possible by merely recording tank top-up odometer readings. It is also useful to be able to measure consumption over selected parts of a regular route.

Ideally, the driver should be able to see, from a glance at a convenientlyplaced dial or digital display, how much fuel is being used at any given moment. There is nothing like an instantaneous fuel read-out to draw attention to the heavy right-foot syndrome. For the owner-driver paying his own fuel bills, a running display of consumption is invaluable.

Several add-on fuel meters are now available in the UK. They were developed initially for the use of manufacturers' development and test engineers and are frequently encountered on Commercial Motor's roadtest vehicles.

Diesel fuel meters have to be more complex than their petrol engine counter

parts because they need to take account of the return flow from the injectors (more fuel passes through the injection pump and injectors than is consumed). In the case of orthodox European (Bosch or CAV) jerk-pump systems, up to 8% of the fuel entering the injectors is returned to the tank.

From Switzerland comes the AIC fuel-measuring system, marketed in Britain by a subsidiary of CPH Transport of Leamington Spa. The base model 500H, costing £415, registers only litres used (in hundredths) on a digital counter. It incorporates an electrically-heated spin-on filter, so the installation doubles as a winter protection device.

A remote liquid crystal display counter for mounting in the cab, typically on top of the fascia, is listed as an extra. It can be zeroed for trip fuel measurement, but only with a removable key.

MORE VERSATILE

AIC's more versatile 200211 fuel monitor, priced at £790, comes complete with an illuminated dashboard display box, on which can be selected: fuel used (in litres or gallons); consumption to date (on a journey); instantaneous consumption (in lit/100km or mpg); distance travelled; time elapsed, and speed. The 200211 meter requires a transmission signal input (picked up by a pulse generator supplied with the unit) from the tachograph drive. An accuracy of ±1% of fuel used is claimed for the AIC range.

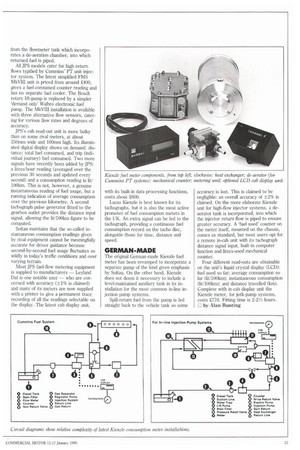

JPS Engineering is a small company based in Solihull which began by developing custom-made fuel flowmeters for use by vehicle manufacturers and on engine test-beds. John Saltau, who designed the system, insists that with a diesel engine the only way to achieve accuracy (quote by JPS at±1.5%) without impeding the engine's fuel supply is for an auxiliary pump to draw fuel from the tank and deliver it, via a generously overspecified fiowmeter, to a small subsidiary tank which uses float valves to maintain a fixed level. The engine draws its fuel direct from the Idowmeter tank which incorporates a de-aeration chamber, into which returned fuel is piped.

All JPS models cater for high return flows typified by Cummins' PT unit injector system. The latest simplified FMS MkVIII unit is priced from around 2400, gives a fuel-consumed counter reading and has no separate fuel cooler. The Bosch rotary lift-pump is replaced by a simpler 'demand only' Vilalbro electronic fuel pump, The MkVIII installation is available with three alternative flow sensors, catering for various flow rates and degrees of accuracy.

JPS's cab read-out unit is more bulky than on some rival meters, at about 250mm wide and 100mm high. Its illuminated digital display shows on demand: distance; total fuel consumed, and trip (individual journey) fuel consumed. Two more signals have recently been added by JPS: a litres/hour reading (averaged over the previous 30 seconds and updated every second) and a consumption reading in lit/ 100km. This is not, however, a genuine instantaneous reading of fuel usage, but a running indication of average consumption over the previous kilometre. A second tachograph pulse generator fitted to the gearbox outlet provides the distance input signal, allowing the lit/100km figure to be computed.

So'tau maintains that the so-called instantaneous consumption readings given by rival equipment cannot be meaningfully accurate for driver guidance because second-by-second fuel usage fluctuates so wildly in today's traffic conditions and over varying terrain.

Most JPS fuel-flow metering equipment is supplied to manufacturers — Leyland Daf is one notable user — who are concerned with accuracy (±1% is claimed) and many of its meters are now supplied with a printer to give a permanent trace recording of all the readings selectable on the display. The latest cab display unit, with its built-in data processing functions, costs about 2600.

Lucas Kienzle is best known for its tachographs, but it is also the most active promoter of fuel consumption meters in the UK. An extra signal can be fed to the tachograph, providing a continuous fuel consumption record on the tacho disc, alongside those for time, distance and speed.

GERMAN-MADE

The original German-made Kienzle fuel meter has been revamped to incorporate a separate pump of the kind given emphasis by Soltau. On the other hand, Kienzie does not deem it necessary to include a level-maintained auxiliary tank in its installation for the most common in-line injection pump systems.

Spill-return fuel from the pump is fed straight back to the vehicle tank so some

accuracy is lost. This is claimed to be negligible: an overall accuracy of -±2% is claimed. On the more elaborate Kienzle unit for high-flow injector systems, a deaerator tank is incorporated, into which the injector return flow is piped to ensure greater accuracy. A 'fuel used' counter on the meter itself, mounted on the chassis, comes as standard, but most users opt for a remote in-cab unit with its tachograph distance signal input, built-in computer function and litres-used mechanical counter.

Four different read-outs are obtainable on the unit's liquid crystal display (LCD): fuel used so far; average consumption so far (lit/100km); instantaneous consumption (lit/1001(m); and distance travelled (km). Complete with in-cab display unit the Kienzle meter, for jerk-pump systems, costs £778. Fitting time is 2-21/2 hours.

by Alan Bunting