Carrying Pulverized Coal in Tankers

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

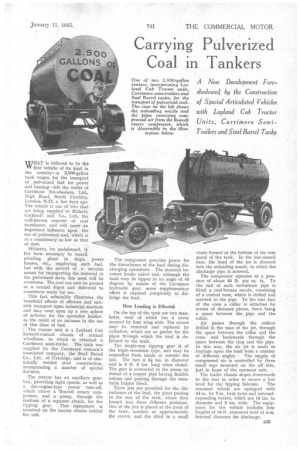

WHAT is believed to be the VV first vehicle of its kind in the country—a 2,500-gallon tank wagon for the transport of pulverized fuel for power and heatingleft the works of Carrimore Six-wheelers, Ltd., High Road, North Finchley, London, N.12, a few days ago. The vehicle is one of two that . are being supplied to Rickett, Cockerell and Co., Ltd., the • well-known concern of coal merchants, and will exert an important influence upon the use of 'pulverized coal, which is of a consistency as low as that of dust.

Hitherto, we understand, if has been necessary to install grinding plant in ships, power houses, • etc., employing such fuel, but with the adverit of a suitable means for transporting the material in the pulverized state, this need will be overcome. The coal can now be ground at a central depot and delivered to consumers ready for use.

This fact admirably illustrates the beneficial effects of 'efficient and suitable transport upon industrial, methods and may even open up a new sphere of activity for the specialist haulier, as the result of an increase in the use of this class of fuel.

' .The tractor unit, is a Leyland Cub forward-control chassis of normal wheelbase, to which is attached a Carrimore semi-trailer. The tank was supplied by the Carrimore concern's associated company, the Steel. Barrel Co., Ltd., of Uxbridge, and is of electrically . welded steel construction, incorporating a number of special features.

The tractor has an auxiliary gearbox, providing eight speeds, as well as afire-engine-type power take-off; which drives a Reavell rotary compressor, and a pump, through the medium of :a separate . clutch, for the tipping gear. This equipment is mounted on the tractor chassis behind the cab.

The compressor provides power for the disturbance of the load during discharging operations. The material becomes firmly caked and, although the tank may be tipped to an angle of 43 degrees by means of the Carrimore hydraulic gear, some' supplementary effort is required completely to dislodge the load.

How Loading is Effected.

On the top of the tank are two manholes, each of which has a cover secured by four wing nuts. The covers may be removed and replaced by cylinders, which act as guides for the pipes through which the load is delivered to the tank.

The single-ram tipping gear is of the triple-extension type, and may be controlled from inside or outside the cab. The ram is 5 ins, in diameter and is 6 ft. 5 ins, long when closed. The gear is connected to the pump by means of a copper pipe having flexible unions and passing through the turntable bolster block.

. Three jets are provided for the disturbance of the load, the pipes passing to the rear of the tank, where they branch into three different positions. One of the jet's is placed at the front of the tank, another at approximately the centre, and the third in a small chute formed at the bottom of the rear panel of the tank. In the last-named case, the head of the jet is directed into the unloading nozzle, to which the discharge pipe is screwed.

The compressor operates at a pressure of about 30 lb. per sq. in. To the end of each turbulence pipe is fitted a cast-bronze nozzle, consisting of a conical nose, which is drilled and screwed to the pipe. To the rear face of the cone a collar is attached by means of distance pieces, there being a space between the _ pipe and the collar.

Air passes through the orifices drilled in the nose of the jet, through the space between the collar and the cone, and backwards through the space between the ring and the pipe. In this way, the air jet is made to impinge upon the load from a number of different angles: The supply of compressed air is controlled by three small taps mounted on the off side, just in front of the rearmost axle. • The trailer chassis slopes downwards to the rear in order to secure a low level for the tipping fulcrum. The rearmost wheels are equipped with 34-in. by 7-in, twin tyres and internalexpanding brakes, which are 16 ins, in diameter and 3 ins. wide. The equipment for the vehicle includes four lengths of 16-ft. armoured hose of 4-in. internal diameter for discharge.