For DRIVERS, MECHANICS & FOREMEN.

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS is paid to The wader of any letter which we publish on. This page, and an EXTRA FIVE SHILLINGS to the sender of the omywhich we select as being The best each week. All notes are edited before being I ublished, Mention your employer's name, in confidence, as evidence of goo:a faith. Addries, .Q., M. and "The conimereal. Motor," 7-15, Rosebery Avenue, London, /. •

Lamps Alight,

On. Saturday, January 15th, light yokir lainps at 4,47 in London, 4.35 in Edinburgh, 4.35 in Newcastle, 4.50 hi Liverpool, 4.50 in Birmingham, 4.57 in Bristol, and 5.33 in Dublin.

A Dual Ignition Gadget.

The sender of the following communication has bffn, awarded the extra paynient of Sc. this. week.

[2176] " C.F." (Walsall) writes I have a lorry

in my charge fitted with a four-cylinder engine of 127 mm. bore. It is practically impcssible to crank this engine speedily enough to enable it to start off

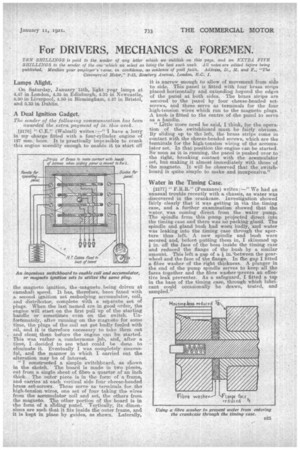

the magneto ignition, the -magneto. being driven at camshaft speed. It has, therefore, been fitted with a second ignition set embodying accumulator, coil, and distributor, complete With a separate set of plugs. When the laSfnamed are in good Or.cler, the engine will. star. t on the first pull up of the starting handle or sometimes even on the switch. Unfortunately, after running on the magneto for some time, the plugs of the coil set get badly fouled with oil, and it is therefore necessary to take them out and clean them before the engine can be started. This was rather a cumbersome jelo, and, after a time, I decided to see what could be done to eliminate it.. Eventually I was completely successful, and the manner in which I cairried out the alteration may be of interest. " I constructed a simple switchboard, as shown in the sketch. The board is made in two pieces, cut from a single sheet of fibre a quarter of an inch thick. The outer piece is in the form of a frame, and carries at each vertical side four cheese-headed brass set-screws. These serve as tenninals for thet high-tension wires, one set of -four taking the wires from the accumulator coil and .set, the others from the magneto.other portion of the board is in

the form of a a 'h

n panel. Vertioally; its dimen

sions are such that it fits inside the outer frame, and. it is kept in place by guides, as shown. Laterally, it is narrow enough to allow of movement from side to side.. This panel is fitted with four brass strips placed horizontally and extending beyond the edges of the panel at both sides. The brass strips are secured to the panel by four cheese-headed setscrews, and these serve as terminals for tho four high-tension wires which run to the magneto plugs. A knob is fitted to the centre of the panel to serve as a handle.

"Little more need be said, I think, for the operation of tlio switchboard must be fairly obvious. By sliding up to the left, the brass strips come in contact with the cheese-headed screws, which are the terminals for the high-tension wiring of the accumulator set. In that position the engine can be started. So soon as it is running, the panel is pushed over to the right, -breaking contact with the accumulator set, but making it almost iininediately with those of the magneto. It will be observed that the switchboard is quite simple to make and inmpensive."

Water in the Timing Case.

' [2177] " F.R.R." (Penzance) writes:--" We had an unusual trouble recently with -achassis, as water was discovered in the crankcase. Investigation showed fairly clearly that it was getting in via the timing case, and a further examination showed that the water\ was coming direct from the water pump. The spindle from this pump projected direct into the timing case and there was no packing gland. The spindle and gland bush had worn badly, and. water was leaking into the timing case through the aperture thus left. A new spindle and bush were secured and, before putting them in' I skimmed up it in. off the face of the boss inside the timing case and reduced the flange of the bush by a similar amount. This left a gap of a in.lbetween the gearwheel and the face of the flange. In the gap I fitted. a fibre washer of the right thickness. A plunger in the end of the pump spindle serves to keep all the faces together and the fibre washer Troves an effective leak preventer. As a safeguard, I fitted a tap in the base of the timing case, through which lubricant could occasionally be drawn, tested, and sampled."