The Shepherd " Easily-tired " Wheel.

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

There is some little difficulty in finding an adequately-descriptive title for the special form of wheel

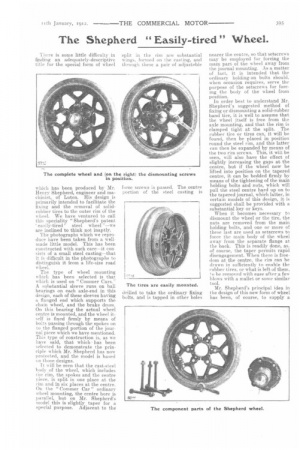

which has been produced by Mr. Henry Shepherd, engineer and machinist, of Luton. His design is primarily intended to facilitate the fixing and the removal of solidrubber tires to the outer rim of the w heel. We have ventured to call this speciality "Shepherd's patent ' ea sily-tired ' steel wheel "—we are inclined to think not inaptly.

The photographs which we reproduce have been taken from a wellmade little model. This has been constructed with such care—it consists of a small steel casting—that it is difficult in the photographs to distinguish it from a life-size road wheel.

The type of wheel mounting which has been selected is that which is used on " Commer Cars.' A substantial sleeve runs on ball bearings on ea-ch axle-end in this design, each of these sleeves having a flanged end which supports the chain wheel, and the brake drum. On this bearing the actual wheel centre is mounted, and the wheel itself is fixed firmly by means of bolts passing through the spokes on to the flanged portion of the journal piece which we have mentioned. This type of construction is, as we have said, that which has been selected to demonstrate the principle which Mr. Shepherd has nou protected, and the model is based en those designs.

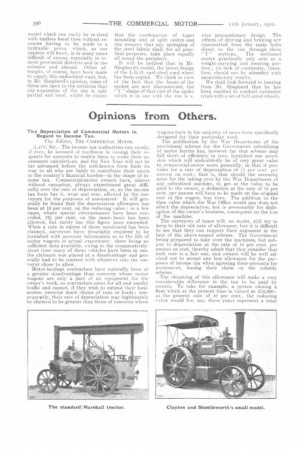

it will be seen that the cast-steel body of the wheel, which includes he rim, the spokes and the centre piece, is split in one place at the rim and in six places at the centre. On the "Commer Oar" ordinary wheel mounting, the centre bore is parallel, but on Mr. Shepherd's model this is slightly taper for a special purpose. Adjacent to the split in the rim are substantial wings, formed on the casting, and through these a pair of adjusteble force screws is passed. The centre portion of the steel casting is drilled to take the ordinary fixing bolts, and is tapped in other holes

nearer the centre, so that setscrews may be employed for forcing the main part of the wheel away from the journal mounting. As a matter of fact, it is intended that the ordinary holding-on bolts should, when occasion requires, serve the purpose of the setscrews for forcing the body of the wheel from position. in order best to understand Mr. Shepherd's suggested method of fixing or dismounting a solid-rubber band tire, it is well to assume that the wheel itself is free from the axle mounting, and that the rim is clamped tight at the split. The rubber tire or tires can, it will be found, then be placed in position round the steel rim, and this latter can then be expanded by means of the two rim screws. This, it will be seen, will also have the effect of slightly increasing the gaps at the centre, but if the wheel now be lifted into position on the tapered centre, it can be bedded firmly by means of the tightening of the main holding bolts and nuts, which will pull the steel centre hard up on to the tapered journal, which latter, in certain models of this design, it is suggested shall be provided with a substantial key or keys.

When it becomes necessary to dismount the wheel or the tire, the nuts are removed from the main holding bolts, and one or more of these lastare used as setscrews to force the main body of the wheel away from the separate flange at the back. This is readily done, as, of course, the taper permits rapid disengagement. When there is freedom at the centre, the rim can he drawn in sufficiently to enable the rubber tires, or what is left of them., o be removed with ease after a few blows with a mallet or some similar tool.

Mr. Shepherd's principal idea in the design of this new form of wheel has been, of course, to supply a

model which can easily be re-tired with endless band tires without recourse having to be made to a hydraulic press, which, as our readers will know, is in many cases difficult of access, especially in remote provincial districts and in the colonies and abroad. Other attempts, of course, have been made to supply this undoubted want, but, in Mr. Shepherd's opinion, some of these are open to the criticism that any expansion of the rim is only partial and local, whilst he claims that the combination of taper mounting and of split centre and rim ensures that any springing of the steel fabric shall, for all practical purposes, take place equally all round the periphery.

It will be noticed that in Mr. Shepherd's model, the latest design of the L.G.O. cast-steel road wheel has been copied. We think in view of the fact that the bases of the spokes are now disconnected, the " Y " shape of that end of the spoke which is in one with the rim is a

wise precautionary design.. The effects of driving and braking are transmitted from the main bolts direct to the rim through these "

Y" sections. The sectioned centre practically only stets as a weight-carrying and locating portion; its lack of continuity, therefore, should not be attended with unsatisfactory results.

We shall look forward to hearing from Mr. Shepherd that he has been enabled to conduct extensive trials with a set of full-sized wheels.