Tuning in for petrol economy

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

The key to running an economical petrol fleet lies in effective engine maintenance, says Stephen Gray. Photographs by Steve Back

DESIGNERS can, and often do, build all the innovations they like into a petrol engine, but unless there is proper engine maintenance carried out, such innovations will be to little avail.

Developments such as cross-flow cylinder heads and hemispherical combustion chambers have helped the relatively inefficient petrol engine. Water heated manifolds improve warm-up time, as do viscous fan units.

But it's no good having a vehicle equipped with a viscous fan, for example, if the fan drive is constantly engaged. If this happens, warm-up time will be increased and the engine will probably be over-cooled during normal running, as it will have been designed to operate with reduced fan effort.

Similarly, when the thermostat gets stuck in the open position, the engine will never reach its normal operating temperature.

Thermostats are very cheap to buy, and can save an operator a lot in terms of fuel wastage, as well as increasing oil life by preventing condensation forming and emulsifying the lubricant.

The thermostat itself can easily be checked by immersing it in boiling water. At the preset temperature (usually stamped on the base of the thermostat) the unit should open.

If, when it is removed from a cold engine, the thermostat is stuck in the open position, it should be discarded immediately and a new one inserted.

The difference in fuel consumption between an engine running at its correct temperature and one that is not is dramatic, often up to 20 per cent.

A simple check should be kept on the vehicle's temperature gauge to ensure that the needle stays in the normal' position.

For those petrol engined vehicles engaged on stop/start delivery work which are not equipped with a fuel saving viscous fan, there are proprietary makes of electric fan availaole.

These replace the existing fan and are thermostatically controlled so that they cut in only if the temperature rises above a pre-determined point.

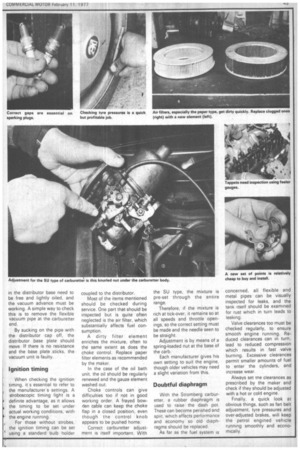

Of course, cool running is not the only factor to influence petrol consumption, though it is a major one. A careful check should be made on the vehicle's spark plugs and points.

For example a worn out set of plugs can actually waste fuel, while a new set only costs a few pounds to install. Its important too to fit the right plugs for the vehicle in question.

Always consult the manu facturer's handbook for the type recommended, and ensure that the correct gap setting is used. This is essential to maintain peak efficiency and therefore economy.

If the engine is using slightly too much oil, the plugs can become fouled. In this case, a harder, or hotter plug can be used to burn off the oil. These, though, have a shorter lifespan than conventional plugs.

False economy

Contact breaker points are equally important, and again, the correct gap should be set. If the points themselves are pitted, throw them out and fit new ones. It is false economy to clean the contacts if they are worn out.

Still on the subject of ignition, a periodic inspection of the plug leads and distributor cap is vveii worth Corrosion can build up where the leads join the cap. Where brass ends are fitted, they should be cleaned to make a more positive contact, while the cap itself should be examined for any minute cracks in the plastic.

These may not immediately affect the running of the engine, but damp conditions can conduct the spark along the crack, thus reducing its effectiveness.

Another tip is to make sOre that the carbon brush is making contact with the top of the rotor arm, as often, the brush sticks into the cap, despite being spring loaded.

ignition timing is another important aspect of petrol economy, but it s no good setting the timing if the distributor IS not functioning properly.

The mechanical bob-weights in the distributor base need to be free and lightly oiled, and the vacuum advance must be working. A simple way to check this is to remove the flexible vacuum pipe at the carburetter end.

By sucking on the pipe with the distributor cap off, the distributor base plate should move. If there is no resistance and the base plate sticks, the vacuum unit is faulty.

Ignition timing

When checking the ignition timing, it's essential to refer to the manufacturer s settings. A stroboscopic timing light is a definite advantage, as it allows the timing to be set under actual working conditions, with the engine running.

For those without strobes, the ignition timing can be set using a standard bulb holder coupled to the distributor.

Most of the items mentioned should be checked during service. One part that should be inspected but is quite often neglected is the air filter, which substantially affects fuel consumption.

A dirty filter element enriches the mixture, often to the same extent as does the choke control. Replace paper filter elements as recommended by the maker.

In the case of the oil bath unit, the oil should be regularly renewed and the gauze element washed out Choke controls can give difficulties too if not in good working order. A frayed bowden cable can keep the choke flap in a closed position, even though the control knob appears to be pushed home.

Correct carburetter adjustment is itself important. With the SU type, the mixture is pre-set through the entire range.

Therefore, if the mixture is rich at tick-over, it remains so at all speeds and throttle openings, so the correct setting must be made and the needle seen to be straight.

Adjustment is by means of a spring-loaded nut at the base of the carb.

Each manufacturer gives his own setting to suit the engine, though older vehicles may need a slight variation from this.

Doubtful diaphragm

With the Stromberg carburetter, a rubber diaphragm is used to raise the dash pot. These can become perished and split, which affects performance and economy so old diaphragms shouid be replaced.

As far as the fuel system is concerned, all flexible and metal pipes can be visually inspected for leaks, and the tank itself should be examined for rust which in turn leads to leaking.

Valve clearances too must be checked regularly, to ensure smooth engine running. Reduced clearances can in turn, lead to reduced compression which results in fast valve burning. Excessive clearances permit smaller amounts of fuel to enter the cylinders, and increase wear.

Always set me clearances as prescribed by the maker and check if they should be adjusted with a hot or cold engine.

Finally, a quick look at obvious things, such as fan belt adjustment, tyre pressures and over-adjusted brakes, will keep the petrol engined vehicle running smoothly and economically.