1011 THE FUEL DRAG

Page 27

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

One of the latest fields of fuel-saving devices is that of wind resistance. CM investigates some of the more recent innovations...

AIR DRAG costs an operator money -in some cases, a lot more money than most people realise.

_Take the case of me 32-ton artic needing nearly 150 horsepower to enable it to cruise at 80km /50moh). At 96km/h (60 mph) merely the effect of air drag will boost the minimum requirement to over 200bhp. A sobering thought, especially in terms of fuel.

The last few years have seen an increasing use of 'bolt-on devices for trucks aimed at reducing air drag, and probably the best known is the Airshield.

Developed in America, by the Rudkin-Wiley Corporation, the Airshield is marketed in the UK by CT (London) Ltd of 3 Hobart Place, London.

In fact the Airshield is net lust one device, it is several. Which particular fitting or combination of fittings to be used depends on the type of vehicle. The most obvious part of the'Airshield is the deflector which is mounted on the roof of the cab. A simple bracket system is used for mounting, which requires drilling through the cab roof to bolt the structure in place.

CT (London) estimates that the whole fitting job should take about two hours. Some reinforcement inside the roof of the cab shell is normally necessary, as well as a three or four bolt attachment.

Two basic types of deflector are available for the truck market, one for rigids and the other for tractor/trailer combinations.

One point which is stressed very strongly by Airshield is that the deflector must be the correct height, in relation to the height of the trailer or box above the cab roof, in order to achieve the maximum efficiency of the device.

Because of this point, the Airshield units are manufactured in a range of heights from 530 to 1150mm (21 to 45in) in increments of 50mm (2m).

FOr rigids, the Airshield can be specified with or without the back fin, which is designed to fill in the gap' behind the deflector and help prevent the build up in vortices created in this area.

The deflectors themselves are moulded in 9.5mm (3/ain) thick phrenolic fibreboard with an extruded aluminium surround.

With boxvan trailers, the principle is the same, only this back fin or vortex stabiliser is mounted on the front bulkhead. The fin is made from grp in a wedge section.

One side effect of the combination, according to Airshield, is that stability in cross-winds is improved.

CT (London) has found that few operators are using the van-mounted vortex stabilisers. This is because, in most fleets there are far more trailers than tractive units, and these are quite often of varying size and shape, so the operator is opting for, the cab-mounted deflector on its own, for the sake of convenience.

The cost of the deflector with a back fin for rigids, including all the associated bracketry, is E193 excluding .VAT. For artics the deflector on its own costs £182 excluding VAT.

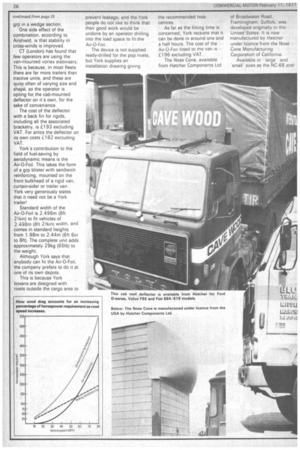

York's contribution to the field of fuel-saving by aerodynamic means is the Air-O-Foii. This takes the form of a grp blister with sandwich reinforcing, mounted on the front bulkhead of a rigid van, curtain-sider or trailer van. York very generously states that it need not be a York trailer!

Standard width of the Air-O-Foil is 2.496m (Bft 21/41n) to fit vehicles of 2.498m t8ft 23/8in) width, and comes in standard heights from 1.98m to 2.44m (6ft 6in to 8ft). The complete unit adds approximately 29kg (661b) to the weight.

Although York says that anybody can fit the Air-O-Foil, the company prefers to do it at one of its own depots.

This is because York boxans are designed with rivets outside the cargo area to prevent leakage, and the -York people do not like to'think that their good work would be undone by an operator drilling into the load space to fit the The device is not supplied ready-drilled for the pop rivets, but York supplies an installation drawing giving the recommended hole centres.

As far as the fitting time is concerned, York reckons that it can be done in around one and a half hours. The cost of the Air-O-Foil fitted to the van is £196 excluding VAT.

The Nose Cone, available from Hatcher Components Ltd of Broadwater Road, Framlingham, Suffolk, was developed originally in the UnitedStates. It is now manufactured by Hatcner under licence from the Nose Cone Manufacturing Corporation of California.

Available in ' large and 'small' sizes as the NC-68 and the NC-48, the Nose Cone costs £130 and £100 respectively, excluding VAT.

Intended for the front of boxvan bodies, be they for rigids or trailers, the Hatcher devices go to a maximum width of 2.5m (8ft 21/2in).

Constructed of white glass fibre, the Nose Cones add an extra 55kg (1 20Ib) and 40kg (901b) for the large and small . sizes respectively to the overall weight. The difference in size between the NC-68 and NC-48 is in height, 1.65 and 1.2m (65 and 451/2in) regpectively.

Hatcher estimates that the fitting time for a Nose Cone is in the region of five hours, and claims that this is a genuine figure for the total time the vehicle will be out of action, not just the time taken in putting in the pop rivets.

For selected makes of truck (Ford D series, Volvo F86 and Fiat 684/619), Hatcher markets a cab roof deflector, wnicn costs i_100 vvith a plain headboard and an extra £10 for built-in illumination.

Estirn\ated fitting time for the cab roof device is about two hours.

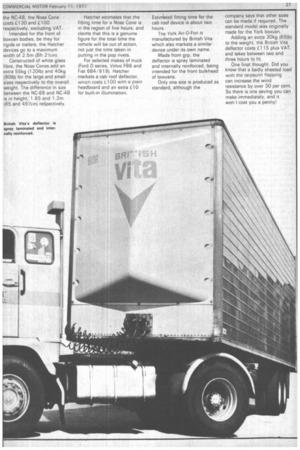

Tne York Air-O-Foli is manufactured by British Vita which also markets a similar device under its own name.

Made from grp, the deflector is spray laminated and internally reinforced, being intended for the front bulkhead of boxvans.

Only one size is produced as standard, although the company says that other sizes can be made if required. The standard model was originally made for the York boxvan.

Adding an extra 30kg (651b) to the weight, the British Vita deflector costs £115 plus VAT, and takes between two and .three hours to fit.

One final thought. Did you know that a badly sheeted load with me tarpaulin flapping can increase the wind resistance by over 30 per cent. So there is one saving you can make immediately, and it won't cost you a penny!