New Sections in

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

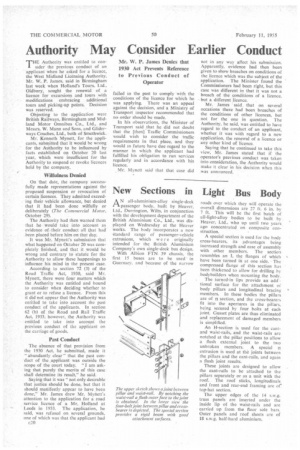

AN all-aluminium-alloy single-deck 1-3. passenger body, built by Heaver, Ltd., Durrington, Wilts, in conjunction with the development department of the British Aluminium Co., Ltd., was displayed on Wednesday at the Heaver works. The body incorporates a new standard range of passenger-vehicle extrusions, which w e re originally intended for the British Aluminium Company's own single-deck bus design.

With Albion FTN 39 chassis, the first 15 buses are to be used in Guernsey, and because of the narrow

Light Bus Body

roads over which they will operate the overall dimensions are 27 ft. 6 in. by 7 ft. This will be the first batch of all-light-alloy bodies to be built by Heaver, Ltd.. who up until two years ago concentrated on composite construction.

A special section is used for the body cross-bearers, its advantages being increased strength and ease of assembly with other members. The section resembles an I, the flanges of which have been turned in at one side, The compressed flange of this section has been thickened to allow for drilling by bodybuilders when mounting the body.

The turned-in lips provide an add.tional surface for the attachment of body pillars and longitudinal bracing members. In these bodies the pillars are of n section, and the cross-bearers fit into the apertures in the pillars, being secured by four bolts at each joint. Gusset plates are thus eliminated and replacement of damaged members is simplified.

An H-section is used for the cantand waist-rails, and the waist-rails are notched at the pillar positions to allow a flush external joint to the two unbroken members. A special rt extrusion is used at the joints between the pillars and the cant-rails, and again a flush joint results.

These joints are designed to allow the cant-rails to be attached to the pillars separately or as a unit with the roof. The roof sticks, longitudinals and front and rear-end framing are or top-hat section.

The upper edges of the 14 s.w.g. truss panels are inserted under the inside lip of the waist-rails and are carried up from the floor sole bars. Outer panels and roof sheets are of 18 s.w.g. half-hard aluminium.