PROGRH,SS IN

Page 112

Page 113

If you've noticed an error in this article please click here to report it so we can fix it.

CHASSIS

D ET A I L

DESIGN

Features of Modern Passenger-vehicle Construction Which Give Improved Performance at Reduced Cost

0 rapid has been the rate of ad vancement in design in major items of passenger-chassis specifications during recent years that one is apt to overlook the importance of details. Features such as six-cylindered engines, servo braking, offset transmission and improved suspension systems have tended to monopolize the stage to the exclusion of important but less obvious factors, such as more efficient oil filters, quieter valve gear, non-binding brake cross-shafts and oil cooling.

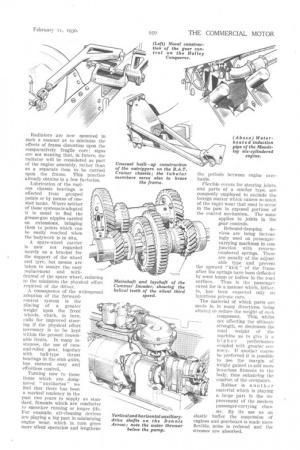

Let us first consider details found in the engine and its auxiliaries. The modern power unit is commonly mounted on rubber blocks and often incorporates a vibration damper, whilst the timing gears are often located at the rear end of the crankshaft in order to reduce the effect of torsional oscillation. Oil purifiers are, to-day, built into the engine as integral parts, giving longer life and reduced operating costs. Distribution drives are quieter by reason of the employment of duplex or triplex roller chains with automatic tension

ing devices, whilst the life of electrical accessories is prolonged by the inclusion of flexible couplings in the drive. Piston slap is minimized by improved design of piston skirts, whilst up-to-date cylinder-head construction permits the use of higher compression ratios. Carburetters

have been improved recently by the addition of devices calculated to increase the rate of acceleration.

The need for the quieter operation of indirect gears has received a large amount of attention and the introduction of the silent third speed marks an epoch in progress in passenger-vehicle construction. Singleshaft control for gearboxes in driverbeside-engine chassis is becoming an accepted practice and the possibility of frame distortion affecting the control is nowadays obviated.

Two-piece propeller shafts are universal on vehicles of anything but short wheelbase. These obviate whip and lighten the loads on the universal joints.

Brake-operating mechanisms have been cleaned up in a very satisfactory manner during the past year or two. Non-compensated systems are almost the rule and provision is made, in the case of servo-operated brakes, for ordinary mechanical operation should a failure of the servo motor take place. Radiators are now mounted in such a manner as to minimize the effects of frame distortion upon the comparatively fragile core; signs are not wanting that, in future, the radiator will be considered as part of the engine assembly, rather than as a separate, item to be carried upon the frame. This practice already obtains in a few factories.

Lubrication of the various chassis bearings is effected from grouped points or by means of oneshot tanks. Where neither of these systems is adopted it is usual to find the grease-gun nipples carried on extensions, bringing them to points which can be easily reached when the bodywork is in situ.

A spare-wheel carrier is now not regarded merely as a bracket for the support of the wheel and tyre, but means are taken to ensure the easy replacement and withdrawal of the spare wheel, reducing to the minimum the physical effort required of the driver.

A consequence of the widespread adoption of the forwardcontrol system is the placing of. a greater weight upon the front wheels, which, in turn, calls for improved steering if the physical effort necessary is to be kept within the present reasonable limits. In many instances, the use of camand-roller gear, together with ball-type thrust bearings in the stub axles, has ensured easy and effortless control.

Turning now to those items which are designated " auxiliaries " we find that there has been a marked tendency in the past two years to supply as standard, fitments which are conducive to smoother running or longer life. For example, air-cleaning devices are playing a big part in minimizing engine wear, which in turn gives more silent operation and lengthens

the periods between engine overhauls.

Flexible covers for steering joints, and parts of a similar type, are commonly employed to exclude the foreign matter which causes to much of the rapid wear that used to occur in the past in exposed portions of the control mechanism. The same applies to joints in the gear controls.

Rebound-damping de vices are being increas ingly used on passenger carrying machines in con junction with reverse cambered springs. These are usually of the adjustable type and prevent the upward " kick " of the frame after the springs have been deflected by some hump or hollow in the road surface. Thus is the passenger cared for in a manner which, hitherto, has been expected only on luxurious private cars.

The material of which • parts are made is, in many directions, being altered to reduce the weight of each component. This, whilst not affecting the ultimate strength, so decreases the total weight of the machine as to give it a

h I g Ii e r performance coupled with greater economy. If another course be preferred it is possible to use the margin of weight gained to add more luxurious fitments to the body, thus enhancing the comfort of the occupants.

Rubber is another material which is playing a large part in the improvement of the modern passenger-carrying chassis. By its use as an elastic buffer the suspension of engines and gearboxes is made more flexible, noise is reduced and the stresses are absorbed.