PROFILE DORRANS

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

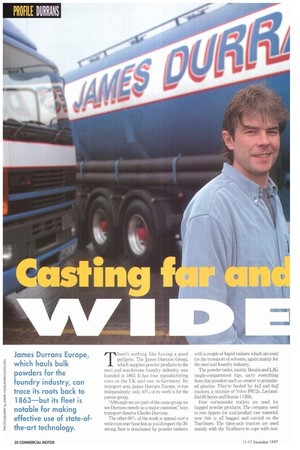

James Durrans Europe, which hauls bulk powders for the foundry industry, can trace its roots back to 1863—but its fleet is notable for making effective use of state-ofthe-art technology. FACT FILE: James Durrans Europe

BASED: Barnsley, South Yorks. CONTACT: Charles Durrans, transport director. FLEET: One 7.5-tonne Leyland Daf, two 17-tonne Scanias; seven Leyland-Daf 85, nine Volvo FH12 and 11 Scania 113M tractors, hauling Tautliner, liquid or powder tanker trailers at 38 tonnes GCW. SPECIALITY CONTRACTS: Transporting powder products onto the Continent.

There's nothing like having a good pedigree. The James Durrans Group, which supplies powder products to the steel and non-ferrous foundry industry, was founded in 1863. It has four manufacturing sites in the UK and one in Germany. Its transport arm, James Durrans Europe, is run independently: only 40% of its work is for the parent group.

"Although we are part of the same group we see Durrans merely as a major customer." says transport director Charles Durrans.

The other 60% of the work is spread over a wide customer base but as you'd expect the 30strong fleet is dominated by powder tankers,

with a couple of liquid tankers which are u:3cd for the transport of solvents, again mainly for the steel and foundry industry.

The powder tanks, mainly Benalu and LAG single-compartment rigs, carry everything from fine powders such as cement to granulated plastics. They're hauled by 4x2 and 6x2 tractors; a mixture of Volvo FH12s, LeylandDaf 85 Series and Scania 113Ms.

Four curtainsider trailers are used for bagged powder products. The company used to run tippers for coal-product raw material; now this is all bagged and carried on the Tautliners. The three-axle tractors are used mainly with the Tautliners to cope with non uniform loading on multi-drop operations.

Backing up the artics are two I7-tonne Scanias and a 7.5-tonne Leyland-Daf 1,7A45, "We're reviewing the use of the 17-tonners on cost-effectiveness," says Durrans, "Most of the work is suitable for artics, which is why we have nothing between 17 and 38 tonnes."

The company employs 32 drivers and three mechanics. "We carry out all the servicing and most repairs on the vehicles and trailers in house," says Durrans. "But if we have a severe problem on a newer truck, perhaps a major engine repair, we find the agent can be a better option, particularly with the latest diagnostic equipment."

Washing and drying

No loading or unloading is carried out at the Barnsley, South Yorks site. The workshop offers tank washing and drying facilities but tanks are usually cleaned at stations throughout the country to suit the pickup and delivery schedules. Although James Durrans is so dependent on the steel industry, the transport arm has been almost unscathed by the contraction and evolution of the UK industry. "We have maintained a good level of business here, although our European operation is a large part of the business," says Durrans. "We average around 35 to 40 Channel crossings per week crossings per week

and use the tunnel "I wouldn't li and ferries in equal amounts. I wouldn't ferry operato like to see the ferry operators squeezed out by the out by the tunnel—

while there's competi tion it's good for pricing and it offers operators like us more flexibility."

No bagged product is taken abroad but bulk powder tanker deliveries range as far as eastern Germany and southern Spain. The company also handles a lot of local work and some deliveries involve extended waiting time. "We average around 80,000 miles per year," says Durrans. "Some of the trucks are on doubleshift work and most drivers keep the same vehicle through its life, which averages six years," explains Durrans.

When it comes to the performance of his vehicles, Durrans has few complaints: "We see 8-8.5mpg, which is not bad considering the time spent blowing the tanks. The Scanias are 360hp and the Volvos 380hp. We believe in giving the driver the right truck to do the job, but I've not been tempted to go to 400hp yet."

With so much of its work overseas the company relies on the vehicle manufacturers' recovery and repair system, and Durrans is full of praise: "We had a Scania in northern Germany which needed a new radiator and the truck was mobile again within one-and-ahalf hours. I called and thanked them for that. I think it only fair; after all, I'd be quick to let them know if I wasn't happy with the service."

Customer base

With its established European customer base is James Durrans Europe planning to expand the fleet? "Not in the near future," says Durrans. "I've seen too many operators go under trying to expand too quickly I feel that the fleet is at a good size now for the operation; you have to keep everything tight and cost-effective, and with the current fleet and staff levels we can do this. To go to the next step, of 40 or maybe 50 vehicles, would be another thing. We would need to increase in all areas, and I'm not sure if that would be cost-effective at the moment."

Durrans' cautious approach to fleet expansion does not mean he's reluctant to invest money in his fleet: "I like technology on trucks which makes the vehicle safer and easier to drive," he says. Every vehicle has some form of retarder; the Volvos have engine brakes and the Scanias have hydraulic retarders. The latest acquisition, a three-axle Leyland-Dal 85 Series tractor, has a ZF Intarder.

Technology also provides Durrans with a link to his trucks.

"We fitted Tracker around five years ago for security purposes, but have found it to be a useful fleet management tool," he reports. A computer screen shows the position of each truck on a map of the UK. "The I 980s seemed to be the peak for mobile phones in cabs, but this system does not require us to speak to the driver we can see the truck on the map," he explains. "This gives better route and time planning and the driver need contact base only if there is a severe problem." problem."

ke to see the The system also allows measurement rs squeezed of response times

from tyre companies

Tunnel." or breakdown opera

tors, and logs data on each vehicle for months at a time. If the vehicle has an accident, this technology could enable the company to prove it was not due to driver or vehicle fatigue, with much more data than a tacho disc. "Its assistance in planning is the most valuable asset to us," Durrans concludes.

_I by Ian Shaw