controlling transport operation

Page 105

Page 106

If you've noticed an error in this article please click here to report it so we can fix it.

MORE THAN 400 vehicles, between them capable of carrying every type of load, are operated by Samuel Williams Transport Ltd, a subsidiary company of Samuel Williams and Sons Ltd. which is itself a member of the Williams Hudson Group of Companies. Operations are centred on Thames Terminal, a 330-acre site at Dagenham where handling and storage facilities for all types of dry and bulk commodities are available and where tankers of up to 42,000 tons can discharge over the company's wharf. The tank farm at the terminal can accommodate some 200,000 tons of bulk fuel and chemical products.

The transport operations are divided between general, international and bulk traffics with a common engineering establishment. It was the bulk traffic operation that I was interested in when I visited Thames Terminal.

Mr Charles Nash is manager of the bulk movements division and has more than 160 tankers under his control ranging from 85 four-wheel rigids of 2000 gal capacity, to 23 eight-wheelers of 3600/4000 gal capacity, and 55 articulated outfits many of which have 6000 gal tanks. Several vehicle manufacturers are represented in the fleet. Leyland, Dodge and Ford are among the four-wheelers, all the eight-wheelers are AECs and the artics are ERF, Atkinson and Swedish Scanias. The company, incidentally recently took delivery of its 100th Scania and this makes it the UK's largest operator of this make. These 100 vehicles, of course, are divided between the three fields of operation.

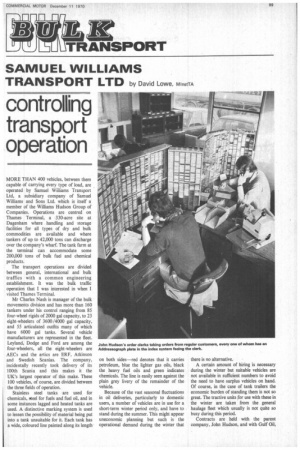

Stainless steel tanks are used for chemicals, steel for fuels and fuel oil, and in some instances lagged and heated tanks are used. A distinctive marking system is used to lessen the possibility of material being put into a tank unsuitable for it. Each tank has a wide, coloured line painted along its length on both sides—red denotes that it carries petroleum, blue the lighter gas oils, black the heavy fuel oils and green indicates chemicals. The line is easily seen against the plain grey livery of the remainder of the vehicle.

Because of the vast seasonal fluctuations in oil deliveries, particularly to domestic users, a number of vehicles are in use for a short-term winter period only, and have to stand during the summer. This might appear uneconomic planning but such is the operational demand during the winter that there is no alternative.

A certain amount of hiring is necessary during the winter but suitable vehicles are not available in sufficient numbers to avoid the need to have surplus vehicles on hand. Of course, in the case of tank trailers the economic burden of standing them is not so great. The tractive units for use with these in the winter are taken from the general haulage fleet which usually is not quite so busy during this period.

Contracts are held with the parent company, John Hudson, and with Gulf Oil,

Phillips Petroleum and Esso Petroleum, also with Tunnel Cement. These contracts vary from oneto three-year periods and the vehicles specified are based at the respective company's terminals along the Thames. Short-term contracts are generally of six months' duration and are held with such companies as Shell-Mex and BP, Amoco, Stevinson Hardy and others to assist them in the peak traffic season.

The vehicles on the long-term conracts are controlled on a day-to-day basis by the hirer and operate from his terminals at such places as Purfleet, Thameshaven, Northfleet, Ancliffe on the Isle of Grain and Thames Terminal (the Samuel Williams base), returning to the central engineering works for maintenance. The oil companies operate in zones centred on the terminals and the vehicles make deliveries to domestic and industrial customers and to retail outlets in the zone.

While vehicles are based at a particular terminal, the drivers are paid by Samuel Williams at the rates of pay and employed under the conditions in force at that terminal. All the terminals have their own pay and productivity agreements, and while the rates of pay at two terminals may be the same, some other factor such as the running times will be different. This, to a certain extent. reduces Samuel Williams' flexibility by inhibiting the change over of drivers between terminals when this sort of action might otherwise be considered to meet operational requirements.

The vehicles on contract to John Hudson are operated from Thames Terminal where the Hudson and Samuel Williams traffic offices adjoin. Orders received by the sales clerks are processed and passed to the traffic office where the details are entered on a weekly sheet. Details of mileages, time, expenses and the use of additional labour are recorded; at the end of a week a summary at the foot of the sheet is completed to show the total amount of the hire charges for the vehicles appearing on the sheet for that week. The summary consists of the totals of excess mileages and excess hours over the standard contract, subsistence and other expenses, the hours worked by mates and the agreed standing charges plus a profit figure. When the sheet is fully completed it is returned to John Hudson as an invoice.

Traffic clerks issue loading instructions and delivery notes plus a security gate pass to the tank farm and collect the signed receipts and log sheets from drivers at the end of the day. Therefore they can see what work the driver has done and this is the source of some of the information which appears on the weekly sheet.

Log sheets are dealt with by a clerk whose sole responsibility this is. He checks all the sheets and issues a daily list of drivers who have failed to hand in a sheet or who have submitted an incomplete or incorrect sheet. He has the authority and the backing of management to ensure that all drivers comply with the records regulations. The new form of drivers' records at first presented some difficulties but now drivers, having been indoctrinated, Hgv driving licences have presented the company with no problems. The firm has its own driving instructors—two drivers who completed a Motec course—two training vehicles and a training area; all drivers trained so far have passed the hgv test. Even company drivers who qualified for licences as of right have been given short refresher courses.

The reduction in drivers' hours resulted in new agreements to increase running times with resultant pay increases.

Although at the time of my visit the announcement of the ending of carriers' licensing as from December 1 (CM October 30) had not then been made, we discussed the effect of such a change on Samuel Williams. Mr Nash thought it would mean a big saving in administrative time and substantial improvement in service. This, he said, had been hampered through the lack of choice and availability of vehicles due to licensing restrictions. A special department within the company dealt solely with carriers' licensing and taxation for all vehicles in the Group.

Vehicle costing has recently been programmed into the computer and computerized monthly returns are being received. This is in the form of a cost per mile figure for every vehicle, enabling a monthly estimate of revenue against cost to be made by Mr Nash.

In a company of this size budgeting is a big job and an annual budget is broken down into monthly figures and a target is set. This is based on past records of capital employed and the profits expected, against which are set known operating costs. Mr Nash said that it gave him a figure to aim for but he pointed out that experience had shown a greater fluctuation in costs in the tanker than in the general haulage division owing to the seasonal nature of the traffic demand.

On the subject of drivers' conditions, Mr Nash described for me the bonus system. The amount increases according to the number of years' service and deductions are made in the event of an accident or loss of equipment such as a hose. The appropriate union is consulted before any stoppage is made. The system is run both on a weekly and an accrued half-yearly basis.

Besides the policy of providing drivers with good conditions of employment and adequate training, management training is not overlooked. Traffic and other clerks receive internal job training, in preparation for promotion to management positions, and departmental managers have all attended courses on the subject of management by objectives.

As a further aid to improved management performance, job specifications are being introduced for all grades of staff and a grading system for clerical positions is due to be implemented shortly subject to approval of the appropriate unions.

The tanker division of Samuel Williams Transport Ltd plays a considerable part in the wide-ranging sphere of activities of the Group which has transport interests as far afield as Vancouver in British Columbia. The services offered form a vital part of the integrated bulk liquid terminal handling, storage and distribution set-up which all started on a patch of the Dagenham marshes in 1887.