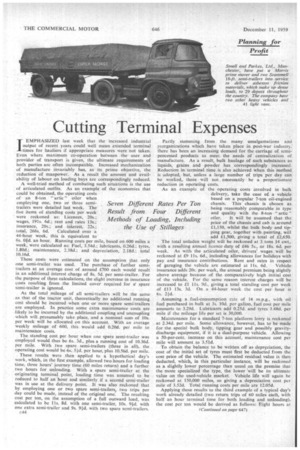

Cutting Terminal Expenses

Page 80

Page 83

If you've noticed an error in this article please click here to report it so we can fix it.

/ EMPHASIZED last week that the increased industrial output of recent years could well mean extended terminal times for hauliers if appropriate measures were not taken. Even where maximum co-operation between the user and provider of transport is given, the ultimate requirements of both parties arc often incompatible. Increased mechanization of manufacture invariably has, as its prime objective, the • reduction of manpower. As a result the amount and availability of labour on loading bays are correspondingly reduced.

A well-tried method of combating such situations is the use of articulated outfits. As an example of the economies that could be obtained, the operating costs of an 8-ton " artic " oiler when employing one, two or three semitrailers were detailed last week. The five items of standing costs per week were reckoned as: Licences, 20s.; wages, 191s. 6d.; rent and rates 13s.; insurance, 20s.; and interest, 22s.; total, 266s. 6d. Calculated over a 44-hour week, this is equivalent to 6s. Old. an hour. Running costs per mile, based on 600 miles a week, were calculated as Fuel, 3.54d.; lubricants, 0.26d.; tyres, 1.80d.; maintenance, 2.38d.; and depreciation, 2.18d.; total 10.16d.

These costs were estimated on the assumption that only one semi-trailer was used. The purchase of further semitrailers at an average cost of around £700 each would result in an additional interest charge of 8s. 5d. per semi-trailer. For the purpose of these calculations, the slight increase in insurance costs resulting from the limited cover required for a' spare semi-trailer is ignored.

As the total mileage of all semi-trailers will be the same as that of the tractor unit, theoretically no additional running cost should be incurred when one or more spare semi-trailers are employed. In practice some extra maintenance costs are likely to be incurred by the additional coupling and uncoupling which will .presumably take place, and a nominal sum of 10s. per week will be allocated on this account. With an average weekly mileage of 600, this would: add 0.20d. per mile to maintenance costs.

The standing cost per hour when one spare semi-trailer was employed would thus be 6s. 3d., plus a running cost of 10.36d. per mile. With two spare semi-trailers (three in all), the operating cost would be 6s, Sid, per hour, plus 10.56d, per mile.

These results were then applied to a hypothetical day's work, which, in the first example, allowed two hours for loading time, three hours' journey time (60 miles return) and a further two hours for unloading. With a spare semi-trailer at the originating terminal point, loading time was assumed to be reduced to half an hour and similarly if a second semi-trailer was in use at the delivery point. It was also reckoned that by employing one or two spare semi-trailers, two trips per day could be made, instead of the original one. The resulting cost per ton, on the assumption of a full outward load, was calculated to be us. 8d. with one semi-trailer, 10s. 9+d. with one extra semi-trailer and 9s. 91d. with two spare semi-trailers. Partly stemming from the many amalgamations and reorganizations which have taken place in post-war industry; there has been an increasing demand for the carriage of semiprocessed products to meet the needs of centralization of manufacture. As a result, bulk haulage of such substances as liquids, grains and powder has correspondingly increased. Reduction in terminal time is also achieved when this method is adopted, but, unless a large number of trips per day can be worked, there will not necessarily be a proportionate reduction in operating costs.

As an example of the operating costs involved in bulk delivery, take the case of a vehicle based on a popular 7-ton oil-engined chassis. This chassis is chosen as being reasonably gomparable in type and quality with the 8-ton " artic " oiler. It will be assumed that the price of the chassis and cab is around £1,150, whilst the bulk body and tipping gear, together with painting, will add £1,500, giving a total of £2,650. The total unladen weight will be reckoned at 3. tons 14 cwt., with a resulting annual licence duty of £46 5s., or 18s. 6d. per week. As with the articulated oiler, drivers' wages will be reckoned at 5.9 1 ls. 6d., including allowances for holidays with pay and insurance contributions. Rent and rates in respect of garaging the vehicle are estimated at 1 ls. 6d. Vehicle insurance adds 20s. per week, the annual premium being slightly above average because of the comparatively high initial cost of the vehicle. For the same reason interest charges will be increased to £1 lls. 9d., giving a total standing cost per week of £13 13s. 3d. On a 44-hour week the cost per hour is 6s. 21d.

Assuming a fuel-consumption rate of 14 m.p.g.. with oil fuel purchased in hulk at 3s. 10d. per gallon, fuel cost per mile amounts to 3.29d. Lubricants add 0.25d. and tyres 1.48d. per mile if the mileage life per set is 30,000.

Maintenance for a standard 7-ton platform lorry is reckoned at 2.34d. per mile. Some allowance, however, has to be made for the special bulk body. tipping gear and possibly gravitydischarge equipment, if it is a dual-purpose vehicle. Allowing a 50-per-cent. increase on this account, maintenance cost per mile will amount to 3,51d.

To obtain the balance to be written off as deprgciation, the cost of the initial set of tyres must first be deducted from the cost price of the vehicle. The estimated residual value is then deducted, which, in this particular instance, will be reckoned as a slightly lower percentage than usual on the premise that the more specialized the type, the lower will be its ultimate value on the used-vehicle market. Vehicle life will again be reckoned at 150,000 miles, so giving a depreciation cost per mile of 3.52d. Total running costs per mile are 12.05d.

Applying these results to the third example of a typical day's work already detailed (two return trips of 60 miles each, with half an hour terminal time for both loading and unloading), the cost per ton would be derived as follows! Eight hours at 6s. 21d. (12 9s: 8d.); 120 miles at 12.05d. (i6 Os. 6d.); total (for 14 tons), £8 10s. 2d., or 12s. 11d. per ton.

• Another way of dealing with terminal delays is by the..use of stillages. • This method provides a similar advantage in traffic scheduling to that given by articulation-availability of one or more spare platforms or bodies. The fundamental difference is that a stillage is carried rather than hauled, and so does not require to be mobile. As a result a stillage body with 17-ft. 3-in. by 7-ft. 6-in platform would be substantially cheaper than a platform semi-trailer of similar dimensions. The comparative •eosts Would be around £175 and £700 respectively. , The lack of mobility of the stillage, when the parent vehicle was not available, would be Only .a slight disadvantage compared with articulation. Whilst semi-trailers can be manhandled to some extent in the 'absence of the tractor unit, the practice is limited in application.

In addition to the stillages, lifting and lowering equipment has to be fitted to the vehicle. I will assume that a 7-ton oil-engined chassis is again used and costs £1,150. Allowing £350 for the addition of mechanical handling equipment and a further £50 for painting would give a total of £1,550. With the stillage itself costing 1175, the total is £1,725 for the combined outfit.

With an unladen weight of 34tons, the annual licence duty will be £42 10s., or 17s. per week. Drivers' wages are again assessed at £9 I Is. 6d., in accordance with R.H. (66) for Grade I areas. Rent and rates are reckoned at 1 Is, 6d., as with the bulk vehicle, but insurance is reduced to 17s. 7d. because of the lower initial cost. Similarly, interest charges are now £1 Os. 8d., giving a total standing cost per week of £12 18s. 3d., or 5s. 104d, per hour.

Running Cost

Because the unladen weight is lower than that of. the bulk vehicle, fuel costs per mile will be reckoned slightly less at 3.18d. Lubricants are again assessed at 0.25d., and tyres at 1.48d. per mile. Maintenance coats can be expected to be a little higher than for a standard platform vehicle, and are placed at 2.57d. Depreciation is reckoned to be 2.18d. per mile, giving a total running cost of 9.66d. per mile.

Applying the same principles to the cost of providing additional stillages as to the cost of spare semi-trailers, the additional interest charge on the outlay of £175 for each extra stillage would amount to 2s. per week, or approximately 0.55d. per hour on a 44-hour week.

Estimation of probable maintenance costs of spare stillages must be largely arbitrary until practical experience in individual circumstances has been obtained. Much would depend on the proficiency of drivers, but, in any event, the overall cost should be slight and will be reckoned here at half that assumed for the semi-trailer. On an average weekly mileage of 600 for the parent vehicle, the additional maintenance cost per mile per spare stillage will be reckoned at 0.10(1.

As it is unlikely that only one stillage would be used, the operating costs with which we are concerned here would be 5s. 11d. per hour, plus 9.76d. per mile • when one spare stillage was • emploYed, and 5s. 114d. per hour, plus 9.864. per mile when two spare stillages were available, that is, three in all.'

Applying these results to the same day's work, the Operating cost per day when one spare stillage was used would be 11 hours at 5s. lid. 5s. Id.) and 120 miles at 9.76d. (14 17s. id.), a total of £8 2s. 8d. for 14 tons, or 11S. 71d. per ton.

With a spare stillage at each end, in addition to the one on the vehicle; the day's costwould work out at eight hours at 5s. 114d. (£2 7s. 8d,), plus 120 miles at 1.86d. (£4 .18s. 7d.), a total of £7 6s.. 3d., giving a rate per ton of ids. 51d. •

To complete the comparison, it will be convenient to detail briefly the corresponding operating costs of a 7-ton standard platform oiler. • With an unladen Weight of 3 tons 4 cwt., licence duty will amount to £38 15s. a year, or 15s: 64. per week.: Wages will again be £9 Its. 6d. per week, whilst rent

and rates are reckoned at Ils. • 64. Vehicle: insurance is calculated at 1.7s. 24. per week and interest charges at 18s. 3d. on the basis of an initial outlay of £1,525. The total for these five items of weekly standing costs is £12 13s, Ild., or 5s. 91-d. per hour for a 44-hour week.

Calculating Depreciation

Fuel costs per mile are estimated at 3.07d. and lubricants at 6.25d. . Tyres are reckoned at 1.484. ancr maintenance at 2.34d. Adopting the same procedure as before, depreciation is calculated to cost 1.84(1. per mile, giving a total running cost per mile of 8.98d.

Applying these results to the first example of a day's work .(one return trip involving 60 miles and .two hours' terminal time at each end), the cost per day would represent seven hours at 5s. 9-}cl. (£2 Gs. 41.d.), plus 60 mites at 8.984. (E2 4s. 10d.), giving a total of £4 5s. 2-.1d, With a full load of 7 tons carried on the outward journey only, the rate per ton would be 12s. 2d.

Summariziing the whole of these results, the respective costs per ton are as follows: 8-ton " artie " with one semi-trailer, its. 8d., with two semi-trailers, 10s. 9.0., with three semitrailers, 9s. 9id.; 7-ton chassis and hydraulic equipment, with two stillages, lls. 74d., with three stillages, 10s. 514.; 7-ton bulk-feed vehicle, 12s. 11d..; 7-ton standard platform vehicle, 12s. 2d.

As in "'The Commercial Motor' Tables of Operating Costs," the manufacturer's recommended carrying capacity has been accepted in all the examples quoted here. The additional ton carried by the articulated vehicle must, therefore, inevitably give more favourable tonnage rates for this type. It should be emphasized that the figures given relate only to the operating cost of individual vehicles, without any addition for overhead or establishment costs and profit.

Throughout this comparison of the use of stillages or articulated outfits, calculation on the basis of cost per ton has been emphasized. Acceptable though any cutting of operating costs may be, it should not be overlooked that in addition to reduced terminal .times, both these methods can provide advantages in other directions. On trunk work, substantial transhipment and corresponding double handling can be avoided. This, in turn, can reduce loss through claims for either damage or pilfering. If spare stillages or semi-trailers are available, their use as temporary storage can-provide some

easement of warehousing and distribution problems. S.B.