FAST, SMOOTH, AUTOMATIC

Page 72

Page 73

Page 74

If you've noticed an error in this article please click here to report it so we can fix it.

By

John F. Moon,

A.M.I.R.T.E.

AMPLE power for rapid acceleration and a high maximum speed are essential for a fire appliance. If these can be obtained with the least effort by the driver, so much the better. In this type of vehicle a fully automatic gearbox really comes into its own.

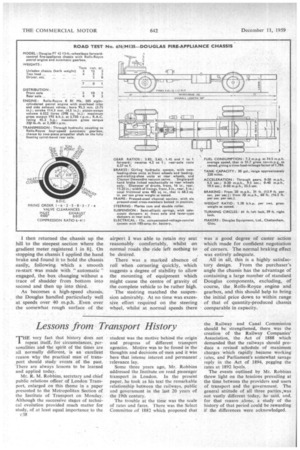

The latest fire-appliance chassis to adopt such trarAmission is the Douglas FT 42, a description of which was published in The Commercial Motor dated August 28. It has a Rolls-Royce eight-cylindered petrol engine producing 195 b.h.p. without excessively high fuel consumption. This makes for a smooth, fast lightweight chassis which is particularly easy to drive, and, because of its straightforward layout, is simple to adapt for the peculiar needs of various fire services throughout the world.

Top Speed Over 60 m.p.h.

An exclusive road test of this first Douglas 4 x 2 fire-appliance chassis showed its ability to reach 50 m.p.h. from a standstill in 33.5 sec., a top speed in excess of 60 m.p.h., and an average fuel-consumption rate of 7.3 m.p.g. when driven over a difficult winding route at an average speed of 34.5 m.p.h.

Braking was found to be well up to the standard of performance. Although the figures quoted in the data panel from 30 m.p.h. are not spectacular for a vehicle running at the weight of the test chassis, the brakes proved to be highly effective from 60 m.p.h. This is a characteristic often found among high-performance sports cars. Their brakes are not necessarily good at low speeds but are first class higher up the speed range.

The chassis layout follows conventional lines, but overall simplicity is commendable. This is typical of (16 Douglas. Their designers invariably aim to make use of a standard channel-section side-member pressing,' which has a constant depth of 9 in. for most of the lighter chassis. This not only facilitates the production of chassis built to special order, but also allows the use of standard cross-members on different types of vehicle.

The drive layout is somewhat unconventional but, nevertheless, in no way complex. The engine and gearbox are unit-mounted, and behind the gearbox there is a double Layrub rubber coupling assembly which incorporates a spacing plate. This feeds the drive into a Douglas power take-off drive box on which is mounted the power drive for the water pump.

This box does not incorporate any transmission gearing and is merely intended to lift the power take-off driving flange above the level of the chassis f ram e. From the back of this drive box a conventional two-piece propeller shaft drives into the Douglas spiral-bevel rear axle.

As offered to me for test, the FT 42 chassis had an unladen kerb weight of 2 tons 121 cwt., and a box of test weights totalling 4 tons 5+ cwt. had been added so that, with myself aboard, the tests were carried out at the gross weight of 7 tons 0-1cwt. This is some 1+ tons less than the maximum recommended gross vehicle weight for this chassis, but it is always difficult to tell exactly at what weight a fire-appliance chassis will be operated until it is placed in actual service.

Braking and acceleration tests were carried out on one of the main runways of Gloucester and Cheltenham airport, allowing me to take acceleration figures up to 50 m.p.h. without causing annoyance on public roads. I would like to have taken figures up to 60 m.p.h., but it was possible to reach this speed in only one direction, and any acceleration figures quoted are always the average of results achieved when running each way.

Study of the acceleration figures quoted reveals particularly good characteristics between 30-50 m.p.h., and this is the speed range over which a fire appliance needs to be nippy in order to cleave a path through congested town traffic.

The chassis had covered only a few miles before I started to test it and, therefore, the brake linings were not bedded in. The stopping distances recorded from 20 m.p.h. and 30 m.p.h. are quite fair in view of the conditions, and when braking from 30 m.p.h. both the rear wheels and the near-side front wheel locked for much of the distance. This would partly be because of the uneven surface of the runway. The hand brake was good, giving 33 per cent. from 20 m.p.h.

To make an accurate check on the maximum speed, permission was

obtained to make a run down another runway which was longer than the one I had used for the braking and acceleration tests, but which was in occasional use by aircraft. To check the speed, the Douglas was paced by my own car, the speedometer of which has been calibrated.

Unfortunately, the brakes on the Douglas proved to be better than those on my car, with the result that I was able to continue accelerating the Douglas to a point much nearer the end of the runway than the driver of my car was able. However, the speedometer of my car registered 60 m.p.h. when the driver had to brake, so it was obvious that by the time I braked my speed was higher.

For a fuel-consumption check I elected to take in a certain amount of town: running and then a stretch of fairly open road. The outward. Mr! was started in the centre of Cheltenham, whence the A435 was taken in the Evesham direction. A distance of nine miles was covered along this road at an average 'speed of 34.7 m.p.h., and the test tank showed that 9-,F pt. of fuel had been used, indicating a consumption rate of 7.39 m.p.g.

. The chassis was then turned towards Cheltenham., this leg being coveted at an average speed of 34.3 M.p.h. and a consumption rate of 7.2 M.p.g. Wherever possible on the open road I was driving at about 40 m.p.h., but at times I had to take the speed up to 50 m.p.h. when overtaking other traffic, a hazardous business at any time on this narrow undulating highway.

.1. consider the average fuel-consumption figure obtained on the two runs. to be quite satisfactory for a v.ehicler_ of this type, particularly as fuel costs are not a big item for the majority of fire brigades and arc secondary to speed and efficiency. For a gradient-performance trial I took the chassis up Leckhampton Hill, where the toad rises some 330 ft. over a distance of a mile, giving an average gradient of approximately 1 in 16. The climb was made in an ambient temperature of 3° L. and the 4-min. ascent produced an engine-coolant

temperature rise of only 8° F., the final temperature being 190° F,.

Unfortunately, the settings .in the gearbox, which govern the speed at which changes are made, seemed to be somewhat awry, with the result. that the third ratio was being held down to 5 m.p.11 before a change Was made into second ratio. -- This was far too low a road speed for third gear, but there was little I could do about it as, although there is a manual over-riding control for this gearbox, it was not connected on the test chassis, as the control quadrant was to be installed by the bodybuilders. Had the box been working correctly, the time of ascent would have been reduced by at least a minute.

To check Lotfade resistance I managed to juggle the temporary manual

control lever into neutral and coasted the chassis down the hill, using the foot brake to keep the speed down to about 20 m.p.h. At the bottom of the hill an emergency stop from 20 m.p.h. produced a Tapley meter figure of 50 -per cent., indicating a reduction in the efficiency through fade of about 20 per cent., which is a reasonable enough drop in view of the unbedded condition of the linings.

1 then returned the chassis up the hill to the steepest section where the gradient meter registered I in 81. On stopping the chassis I applied the hand brake and found it to hold the chassis easily, following which a smooth re-start was made with " automatic " engaged, the box changing without a trace of shudder from bottom into second and then up into third.

As becomes a high-speed chassis, the Douglas handled particularly well at speeds over 40 m.p.h. Even over the somewhat rough surface of the

airport I was able to retain my seat reasonably comfortably, whilst on normal roads the ride left nothing to be desired.

There was a marked absence of roIl when cornering 'quickly, which suggests a degree of stability to allow the mounting of equipment which might cause the centre of gravity of the complete vehicle to be rather high.

The steering matched the suspension admirably. At no time was excessive effort required on the steering wheel, whilst at normal speeds there was a good degree of caster action which made for confident negotiation of corners. The normal braking effect was entirely adequate.

All in all, this is a highly satisfactory design. From the purchaser's angle the chassis has the advantage of containing a large number of standard Douglas components, excluding, of course, the Rolls-Royce engine and gearbox, and this should help to bring the initial price down to within range of that of quantity-produced chassis comparable in capacity.