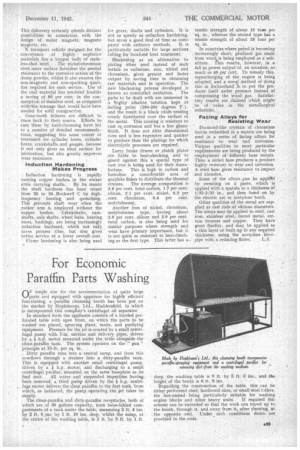

For Economic Paraffin Parts Washing

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

OF ample size for the accommodation of quite large parts and equipped with apparaus for highly efficient functioning, a paraffin cleansing booth has been put on the market by Hopkinsons, Ltd., Huddersfield, in which is incorporated this compIny's centrifugal oil separator. In standard form the appliance consists of a hooded perforated table with open front, on which the parts to be washed .are placed, spraying plant, tanks, and purifying equipment. Pressure for the jet is created by a small centrifugal pump with 1-in. suction and delivery pipes, driven by a 14. motor mounted under the table alongside the clean-paralEn tank. The system operates on the " gun " principle at 15-lb. per sq. in.

Dirty paraffin runs into a central sump, and from this overflows through a strainer into a dirty-paraffin tank. This is equipped with another small centrifugal pump.

driven by a h.p. motor, and discharging to a small centrifugal purifier, mounted on the same baseplate as its feed unit. All water and suspended impurities having been removed, a third pump driven by the h.p. centrifuge motor delivers the clean paraffin to the first tank, from which, as indicated, the pump operating the jet takes its supply.

. The dean-paraffin and dirty-paraffin receptacles, both of which are of 30 gallons capacity, form loose-lidded compartments of a tank under the table, measuring 2 ft. 4 ins. by 2 ft. S‘ins. by 1 ft. 10 ins, deep. whilst the sump, at the, centre of the washing table, is 3 ft. by 3 ft. by 1 ft.

deep, the washing table is 9 ft. by 3 ft. 3 ins., and the height of the booth is 6 ft. 6 ins, Regarding the construction of the table, this can be either perforated steel, hardwood slats, or small steel rallers, the last-named being particularly suitable for washing

engine blocks and other heavy units. If required this scheme can be extended so that the work can travel up tothe booth, through it, and away from it, after cleaning, at _ the opposite end. Under. such conditions doors are provided in the ends.