BEDDING DOWN WITH BOXES

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

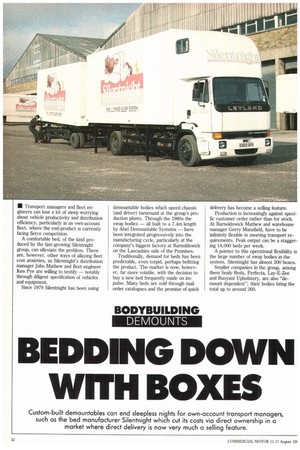

Custom-built demountables can end sleepless nights for own-account transport managers, such as the bed manufacturer Silentnight which cut its costs via direct ownership in a market where direct delivery is now very much a selling feature.

• Transport managers and fleet engineers can lose a lot of sleep worrying about vehicle productivity and distribution efficiency, particularly in an own-account fleet, where the end-product is currently facing fierce competition.

A comfortable bed, of the kind produced by the fast-growing Silentnight group, can alleviate the problem. There are, however, other ways of allaying fleet cost anxieties, as Silentnight's distribution manager John Mathew and fleet engineer Ken Pye are willing to testify — notably through diligent specification of vehicles and equipment.

Since 1979 Silentnight has been using demountable bodies which speed chassis (and driver) ttumround at the group's production plants. Through the 1980s the swap bodies — all built to a 7.4m length by Abel Demountable Systems — have been integrated progressively into the manufacturing cycle, particularly at the company's biggest factory at Barnoldswick on the Lancashire side of the Pennines.

Traditionally, demand for beds has been predictable, even torpid, perhaps befitting the product. The market is now, however, far more volatile, with the decision to buy a new bed frequently made on impulse. Many beds are sold through mail order catalogues and the promise of quick delivery has become a selling feature.

Production is increasingly against specific customer order rather than for stock. At Barnoldswick Mathew and warehouse manager Gerry Mansfield, have to be infinitely flexible in meeting transport requirements. Peak output can be a staggering 14,000 beds per week.

A pointer to this operational flexibility is the large number of swap bodies in the system. Silentnight has almost 200 boxes.

Smaller companies in the group, among them Sealy Beds, Perfecta, Lay-E-Zee and Buoyant Upholstery, are also "demount dependent"; their bodies bring the total up to around 260. At the main Barnoldswick factory, the oading banks are located at the end of the roduction lines. Finished beds are moved straight into waiting boxes. Some are ready for despatch the same day. Others are put into short-term storage prior to assembly of vehicle loads.

OWNER-DRIVERS

Flexibility is also apparent in the group's use of owner-drivers for a percentage of the fleet. At Barnoldswick, of 62 drivers, 24 are self-employed, each with his own rigid (mainly 16.25-tonne) chassis. All the drawbar skeletal trailers and, of course the Abel swap bodies, are companyowned. At other locations, owner-drivers are much thinner on the ground.

No restrictions are placed on the owner-driver's choice of chassis, provided it meets the dimensional criteria of the demountable operation, in terms of length, frame height and twistlock positions.

One of the recent additions to the mixed bag of owner-driyen chassis — in Silentnight livery but with the owner's name and address on the cab doors — is a MAN 16.192 run by John Wrigglesworth of Keighley. It was specified with air suspension on the drive axle, doing away with the need for a second (rear) Abel air bellows lift-pack. The air springs give sufficient lift travel for demounting.

On the negative side the air-suspended MAN 16-tormer has been found to roll more than expected, when carrying a full 2.75m-high body. Wrigglesworth plans to fit a stiffer front anti-roll bar.

Because a bed is relatively light in relation to its bulk, actual gross weights are way below design platings. Most of the rigids are downplated for a GVW of 12 tonnes, which means an annual VED of just 2290 and no extra tax payable in respect of the drawbar trailer. The small 381min (15in) tyres on the trailers bring a 4 tonnes per axle plating limit. In practice, a gross trailer weight of eight tonnes is more than sufficient to cope with a full 7.4m box of even the heaviest Silentnight group beds.

Most of Silentnight's own chassis on the drawbar trunking operation from Barnoldswick are Dodge G13s, downplated from 13 to 12 tonnes GVW. Pye says while they have proved reliable and suited to the demount operation, the Perkins T6.354 engine lacks performance for longhaul motorway work, where the wind-drag of a two-box drawbar combination with a tall cab-top Marsden Vanplan sleeper pod can be formidable.

Some of the owner-drivers, with more powerful chassis like the MAN and a batch of slightly older Gardner 6LXCTengined ERFs, have shown that long distances can be covered much more comfortably, and usually more rapidly, with higher power-weight ratios.

BIGGER ENGINE

Trials with a less expensive, but nevertheless British-built, chassis in the shape of a 172kW (230hp) TL11A-engined Leyland Cruiser have confimied the performance and fuel economy advantages of a bigger engine working well within its capabilities. The Cruiser is road-speed governed for a maximum speed of 901m/h, and is returning consumption figures as good as 23.5 litres/1001cm (12mpg) — better than the harder-working Dodges.

Deliveries of Silentnight beds are made to high street and out-of-town furniture stores, and to private homes, the latter being mail order deliveries through catalogue or advertisement sales.

An 18m drawbar combination can obviously become unmanageable in shopping streets and in residential areas. Silentnight's usual strategy, therefore, is to uncouple the trailer on the outskirts of the built-up area, leaving it in a secure lorry park or on the premises of an accommodating haulier. After making its first delivery, the chassis returns and swaps boxes, enabling delivery of the load in the second box to proceed.

Pye points out that the absence of hydraulics in the Abel lift equipment makes trailer coupling and uncoupling a rapid and hassle-free operation. The drawbar trailers in the fleet are a mixture of orthodox turntable and fixed A-frame centre-bogie units. The latter are preferred by drivers because of ease of reversing, although the more elaborate (and expensive) turntable trailers "follow" better, with less cut-in on corners.

No new trailers have been acquired recently, but it is likely, says Pye, that the centre-bogie type (no longer legally constrained on length) will be favoured when new orders are placed.

Silentnight retains the traditional view of own-account transport, despite exhortations from many contract-hire and leasing concerns to let them relieve the company of its distribution headaches. While contract hire might result in predictable costs, detailed studies by Silentnight have convinced management that direct ownership, making efficient use of transport resources within a controlled budget, results in lower costs. o by Alan Bunting