191.—The Care of Lighting Dynamos.

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

If there is a considerable loss of efficiency in the lighting dynamo, this will often be found attributable to discoloration of the commutator by corrosion or by deposition of a film of carbon from the brushes.

This discoloration or film must be removed as soon as it makes its presence apparent, but it should not be attacked by the, usual method of employing emery cloth or glasspaper. The commutator end cover plate should be removed, the engine started and a piece of clean linen rag pressed to the rotating surface of the commutator by means of a finger. From time to time a small amount of brass cleaning polish should be applied to the rag. The powder in the polishing fluid is sufficiently coarse to serve the purpose of cleaning, and after three or four applications the commutator should be in perfect condition.

192.—Detecting Trouble by Sound.

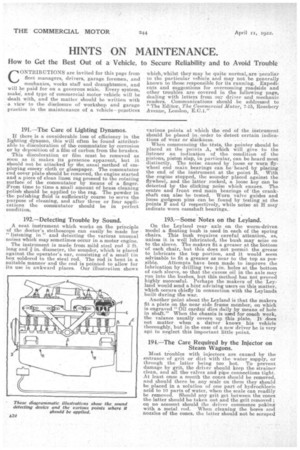

A neat instrument which works on the principle of the doctor's stethoscope can easily be made for "listening in " and detecting the various unusual noises which may sometimes occur in a motor engine.

The instrument is made from mild steel rod 3 ft. long and in. diameter, the sounder, which is placed against the operator's ear, consisting of' a small tin box soldered to the steel rod. The rod is bent in a suitable manner and the end is pointed to allow for its use in awkward places. Our illustration shows

various points at which the end of the instrument should be placed in, order to detect certain indica tions of wear or slackness. • •

When commencing the tests_, the pointer should be placed at the points A, which will give to the listener an indication of the condition of the pistons, piston 'slap, in particular, can be heard most distinctly. The noise caused by loose or worn flywheel end main bearings can be heard by placing the end of the instrument at the point B. With the engine stopped, the sounder placed against the flywheel, and the latter rocked, a loose key can be detected by the clicking noise which ensues. • The centre and front end main bearings of the crankshaft can also be tested. Warn valve guides and loose gudgeon pins can be found by testing at the points F and G respectively, while noise at H may indicate worn camshaft bearings.

193.—Some Notes on the Leyland.

On the Leyland rear axle on the worm-driven model a floating bush is used in each of the spring chairs. This bush requires careful attention, as, unless it is well lubricated, the bush may seize on to the sleeve. The makers fit a greaser at the bottom of each chair, but this does not permit the grease to lubricate the top portion, and it would seem advisable to fit a greaser as near to the top as possible. Attempts have been made to improve the lubrication by drilling two On. holes at the bottom of each sleeve, so that the excess oil in the axle may run into the bushes, but this method has not proved highly successful. Perhaps the makers of the Leyland would send a hint advising users on this matter, which occurs chiefly in connection with the Leylands built during tfie war.

Another point about the Leyland is that the makers fit a plate an the near side frame member, on which is engraved "Oil =damdies daily by means of hole in shaft." When the chassis is used for coach work, the valance usually covers up this plate. It does not matter when a driver knows his vehicle thoroughly, but in the case of a new driver he is very apt to neglect this important little point.

194.—The Care Required by the Injector on Steam Wagons.

Most troubles with injectors are caused by the entrance of grit or dirt with the water supply, or through the latter being too hot. To prevent damage by grit, the driver should keep the strainer clean, and all the valves and pipe connections tight. At least once a month the cones should be removed, and should there be any scale on them they should be placed in a solution of one part of hydrochloric acid to 10 parts of water, when the scale can readily be remover]. Should any grit get between the cones the latter should be taken out and the grit removed ; on no account should the driver commence poking with a metal rod. When cleaning the bores and nozzles of the cones, the latter should not be scraped

with anything made of metal, a piece of wood is the best tool which can be used and one which can be obtained at any time.

As regards the heat of the water supply, if the water lifter blows, it heats the feed water, or the clack valves may be leaking, thus causing steam to blow back into the water. Therefore the joints on the lifter and the clack valves should be kept tight. To start the injector, first turn on the water supply, then slightly open the steam valve, so as to admit steam through the nozzles into the injector. The steam valve may then be fully opened, the supply of water being regulated until there is no overflow of water or escape of steam.