For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

• A PRIZE OF TEN SHILLINGS is awarded each week to the sender of the best letter which we publish on this page; all othere are paid for at the rate of a penny. a line, with an allowance for photographs. All notes are edited before being published, Mention your employer's name, in confidence, as evidence of good faith. Address, D., M. and F., 'The Commercial Motor," 7-25, Rosebery Avenue, London, E.C. 1.

Lamps Alight— Light your lamps at 8.20 in London, 9.12 in Edinburgh, 8.33 in Newcastle, 8.35 in Liverpool, 8.29 in Birmingham, 8.29 in Bristol, and 9.18 in Dublin.

Preparing a Zenith Carburetter for Gas.

The sender of the following communieation has been awarded the ids. prize this week.

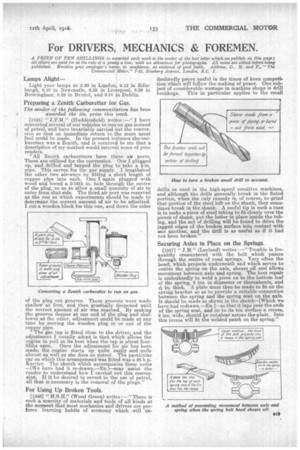

[1845] " J.F.M." (Huddersfield) writes : —" I have converted several of our Vehicles to run on gas instead of petrol, and have invariably carried out the conversion so that an immediate return to the more usual fuel could be made. In the present instance the,carburetter was a Zenith, and it occurred to me that a description of ley method would interest some of your readers.

"All Zenith carburetters have three air ports. These are utilized for the conversion. One I plugged up, and drilled and tapped the plug to take a ien. pipe. This serves for the gas supply. I lengthened the other two air-ways by fitting a short length of copper pipe into each. One. I again plugged with wood and bored a 3-16th in. hole through the centre of the plug; "so as to allow a small quantity of air to enter from that side. The third air pert was reserved as the one at which experiments should be made to determine the correct amount of air to be admitted. I cut a wooden block for this one, and down the sides of the plug cut grooves. These grooves were made shallow at first, and then gradually deepened until the correct amount of air was reached. By making the grooves deeper at one end of the plug and shallower at the other, adjustment could be made at any time by moving the wooden plug in or out of the copper pipe.

copper gas tap is fitted close to the driver, and the adjustment I usually adopt is that which allows the engine to pull at its best when the tap is about fourfifths open. Once the adjustment for air has been made, the engine starts up quite easily and pulls almost as well as she does on petrol. The particular car on which this arrangement was fitted was a 25 h.p. Karrier. The sketch which accompanies these notes —[We have had it re-drawn,—En.)—may assist the reader to understand how I carried out this conversion. If it be desired to revert to the use of petrol, all that is necessary is the removal of the plugs."

For Using Up Broken Tools.

[1846] " H.S.H." (Wood Green) writes :—" There is such a scarcity of materials and tools of all kinds at the moment that most mechanics and drivers are perforce learning habits of economy which will un doubtedly prove useful in the times of keen competition which will follow the making of peace. One subject of considerable wastage in machine shops is drill breakage. This in particular applies to the small

drills as used in the high-speed sensitive machines, and although the drills generally break in the fluted portion, when the only remedy is, of course, to grind that portion of the steel left on the shank, they some, times break in the shank. A useful tip in such a case is to make a piece of steel tubing to fit closely over the pieces of shank, put the latter in place inside the tubing, and the act of drilling will be found to drive the jagged edges of the broken surface into contact with one another, and the drill is as useful as if it had not been broken."

Securing Axles in Place on the Springs.

[1847] " J.H." (Leyland) writes :—" Trouble is frequently encountered with the bolt which passes through the centre of road springs. Very often the head, which projects underneath and which serves to centre the spring on the axle, shears off and allows movement between axle and spring. The best repair is undoubtedly to weld a piece on to the bottom leaf of the spring, 2 ins. in diameter or thereabouts, and AIn. thick. A plate must then be made to fit on the spring bracket so as to provide a suitable connection between the spring and the spring seat on the axle. It should be made as shown in the sketch—{Which we have had redrawn.—EDJ—so that it laps over the ends of the spring seat, and on to its top surface a recess, 2 ins, wide, should be mityclear across the plate. Into this recess will fit the welded patch on the spring."