Steam Wagons and Lorries.

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

Type A.

There are two steam wagons on exhibition at the Agricultural Hail which come under his head. These are the 6-ton steam wagon by Savage Brothers, Limited, St. Nicholas iron Works, King's Lynn, and the 5-tonner shown by The St. Pancras Iron Work Co., Ltd., 171, St. Pancras Road, London, N.W. The features which are common to all steam wagons of this type are : Vertical fire-tube or water-tube boiler; horizontal compound engine ; two-speed gear; differential countershaft; and two chain sprockets which transmit the final drive, through chains, to the rear road wheels. The exact form which the boiler takes is a point which has considerably exercised the ingenuity of individual designers in order to arrive at a boiler that can be cheaply produced, efficient, simple of construction, easy to clean and make renewals, strong and reliable, and on:! which will not prime. The vertical type of boilerlends itself admirably to the general design of a steam wagon, because it takes up so little of the total length of the vehicle, whilst the fittings can be mounted in much more accessible positions than is possible with the majority of loco.-type boilers. The efficiency is not, however, so high as is the case with the latter type. It may be generally stated that boilers of the vertical class, as used on 5-ton or 6-ton steam wagons, have a total heating surface of about go to 95 satiare_feet, with about 4 square feet of 'grate area, and the working pressure is from zoolb. to 2251b. per square inch. All usual and necessary fittings are provided, and these include : pressure gauge; two safety valves; two checkvalves ; and a blow-off cock. The feed water is normally supplied to the boiler by a plunger pump driven from the crankshaft. The compound engine has all the valve motion completely enclosed and running in an oil-bath, and is provided with means whereby high-pressure steam can be stiOplied to the low-pressure cylinder, in order that extra power may momentarily be obtained. The change-speed gear pinions, cut from solid steel, are most often mounted on an extension of the crankshaft, and mesh with machine-cut gear wheels which are mounted on the differential countershaft. The gears provide for two ratios of reduction from engine to road wheels ; the higher one is for all ordinary running, and the lower one is for steep hills, or for very bad roads. The outer ends of the differential shafts are fitted with chain sprockets, from which the drive is taken to the back wheels by means of chains. The Akermann

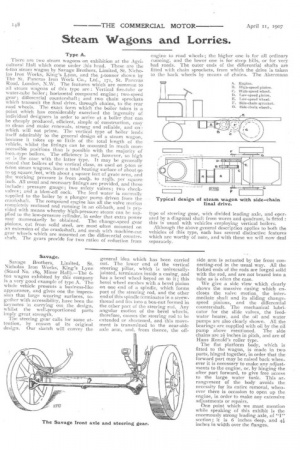

type of steering gear, with divided leading axle, and operated by a diagonal shaft from worm and quadrant, is fitted : this is usual with vehicles employing vertical boilers. Although the above general deScription applies to both the vehicles of this type, each has several distinctive features which are worthy of note, and with these we will now deal separately.