Compact New Overdrive Unit from Albion

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

ASMALL and quite simple, but highly significant component is announced today by . Albion Motors, Ltd., Glasgow, and will be seen at Earls Court,. It is an epicyclic gearbox, situated between the engine flywheel and the main box, which provides an overdrive on all gears, thereby doubling the number of ratios available to the driver. It will be an optional fitting in the first place, to the Clydesdale range of chassis.

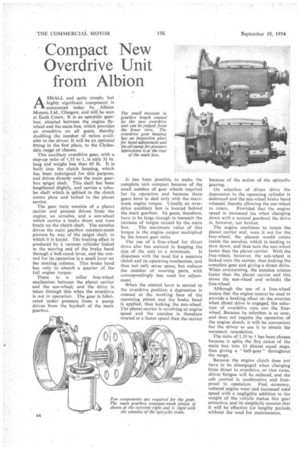

This auxiliary overdrive gear, with a step-up ratio of 1.33 to I, is only 3f in. long and weighs less than 60 lb. It is built into the clutch housing, which has been redesigned for this purpose, and drives directly onto the main gearbox spigot shaft. This shaft has been lengthened slightly, and carries a tubular shaft which is splined to the clutch centre plate and bolted to the planet carrier.

The gear train consists of a planet carrier and pinions driven from the engine, an annulus, and a sun-wheel which carries a brake drum and runs freely on the clutch shaft. The annulus drives the main gearbox constant-mesh pinions by way of the spigot shaft, to which it is keyed. The braking effect is produced by a vacuum cylinder linked to the moving end of the brake band through a bell-crank lever, and the control for its operation is a small lever on the steering. column. This brake band has only to absorb a quarter of the full engine torque. .

There is a roller free-wheel mechanism between the planet carrier and the sun-wheel, and the drive is taken through this when the overdrive is not in operation, The gear is lubricated under pressure from a pump driven from the Iayshaft of the main gearbox. It has been possible to make the complete unit compact because of the small number of gear wheels required for its operation and because these gears have to deal only with the maximum engine torque. Usually an overdrive auxiliary box is located behind the main gearbox. Its gears, therefore, have to be large enough to transmit the increase of torque caused by the Main box. The maximum value of this torque is the engine output multiplied by the lowest gear ratio.

The use of a free-wheel for direct drive also has assisted in keeping the size of the unit to a minimum. It dispenses with the need for a separate clutch and its operating mechanism, and thus not only saves space, but reduces the number of wearing parts, with correspondingly less need for adjustment.

When the control lever is moved to the overdrive position a depression is created at the working face of the operating piston and the brake band is applied, thus locking the sun-wheel. The planet carrier is revolving at engine speed and the annulus is therefore rotated at a faster speed than the carrier because gearing. of the action of the epicyclic On selection of direct drive the depression in the operating cylinder is destroyed and the sun-wheel brake band released, thereby allowing the sun-wheel to rotate. Provided that the engine speed is increased (as when changing down with a normal gearbox) the drive is, however, not broken.

The engine continues to rotate the planet carrier and, were it not for the free-wheel,the planets would rotate inside the annulus, which is. tending to slow down, and thus turn the sun-wheel faster than the planet carrier, With the free-wheel, however, the sun-wheel is locked onto the carrier, thus locking the complete 'gear and giving a direct drive. When overrunning, the annulus rotates faster than the planet carrier and this slows the sun-wheel and unlocks the free-wheel.

Although the use of a free-wheel means that the engine cannot be used to provide a braking effect on the overrun when direct drive is engaged, the selection of overdrive cuts out the freewheel. Because its selection is so easy, and does not require the operation of the engine clutch, it-will be convenient for the driver to use it to obtain the necessary retardation.

The ratio of 1.33 to 1 has been chosen because it splits the five ratios of the main box into 10 almost equal steps, thus giving a " half-gear" throughout the range.

Because the engine clutch does not have to be disengaged when changing from direct to overdrive, or vice versa, driver fatigue will be reduced, and the cab control is unobtrusive and foolproof in operation. Fuel economy, reduced engine wear and increased road speed with a negligible addition to the weight' of the vehicle Makes this gear attractive, and its simplicity ensures that it will be effective for lengthy periods, without the need for maintenance.