A Risurni of Recently Published Patent Specifications

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

A Power Take-off For Tractors

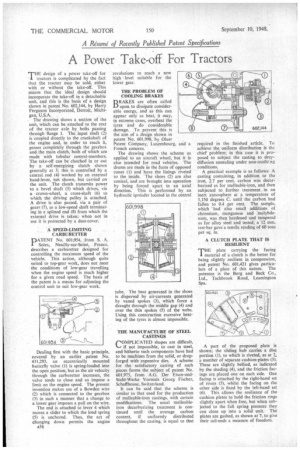

THE design of a power take-off for tractors is complicated by the fact that the tractor may be sold, either with or without the take-off. This means that the ideal design should incorporate the take-off in a detachable unit, and this is the basis of a design shown in patent No. 602,144, by Harry Ferguson Incorporated, Detroit, Michigan, U.S.A.

The drawing shows a section of the unit, which can be attached to the rear of the tractor axle by bolts passing through flange 1. The input shaft (2) is coupled directly to the crankshaft of the engine and, in order to reach it, passes completely through the gearbox and the main clutch, both of which are made with tubular central-members. The take-off can be clutched in or out by a self-energizing clutch shown generally at 3; this is conttolled by a central rod (4) worked by an external hand-lever, not shown, but carried on the unit. The clutch transmits power to a bevel shaft (5) which drives, via a crown-wheel, a cross-shaft (6) to which the driving pulley is attached. A drive is also passed, via a pair of gears (7), to a low-speed shaft terminating in a splined end (8) from which the external drive is taken; when not in use it is protected by a dust-cover.

• A SPEED-LIMITING CARBURETTER PATENT No. 601,954, from S. A. Soles, Neuilly-sur-Seine, France, describes a carburetter designed for controlling the maximum speed of the vehicle. This action, although quite suited to top-gear work, does not meet the conditions of low-gear travelling when the engine speed is much higher for a given road speed. The basis of the patent is a means for adjusting the control unit to suit low-gear work.

Dealing first with the basic principle, covered by an earlier patent No. 431,293, an eccentrically mounted butterfly valve (1) is spring-loaded into the open position, but as the air velocity through the carburetter increases, the valve tends to close and so impose a limit on the engine speed. The present invention makes use of a Bowden wire (2) which is connected to the gearbox (3) in such a manner that a change to a lower gear imposes a pull on the wire.

The end is attached to lever 4 which moves a slider to which the load spring (5) is anchored. Thus, the act of changing down permits the engine a36 revolutions to reach a new high level suitable for the lower gear.

THE PROBLEM OF

COOLING BRAKES DRAKES are often called 1--) upon to dissipate considerable energy, and as this can appear only as heat, it may, in extreme cases, overheat the tyres and do considerable damage. To prevent this is the aim of a design shown in patent No. 601,998, by Olaer

Patent Company, Luxembourg, and a French concern, The drawing shows the scheme as applied to an aircraft wheel, but it is also intended for road vehicles. The drums are made in the form of opposed cones (I) and have the linings riveted to the inside. The shoes (2) are also conical, and are brought into operation by being forced apart in an axial direction. This is performed by an hydraulic spreader located in the central tube. The heat generated in the shoes is dispersed by air-currents generated by vaned spokes (3), which force a draught through the middle gap (4) and over the thin spokes (5) of the webs. Using this construction excessive heating of the tyres is almost impossible.

THE MANUFACTURE OF STEEL CASTINGS

rOMPIACATED shapes are difficult,

if not impossible, to cast in steel, and hitherto such components have had to be machines from the solid, or dropforged with expensive dies. A scheme for the satisfactory casting of such pieces, forms the subject of patent No. 601,975, from A.G. Der Eisen-undStahl-Werke Vormals Georg Fischer, Schaffhouse, Switzerland.

It can be said that the scheme is similar to that used for the production of malleable-iron castings, with certain modifications. The usual malleableiron deearburizing treatment is continued until the average carbon content, if uniformly distributed throughout the casting, is equal to that required in the finished article. To achieve the uniform distribution is the chief problem; in this case it is proposed to subject the casting to deepdiffusion annealing under non-oxidiing conditions.

A practical example is as follows: A casting containing, in addition to the iron, 2.7 per cent, carbon was decarburized as for malleable-iron, and then subjected to further treatment in an inert atmosphere at a temperature of 1,150 degrees C. until -the carbon had fallen to 0.4 per cent. The sample, which had also small additions of chromium, manganese and molybdenum, was then hardened and tempered as for alloy steel and tested; a-12 mm. test-bar gave a tensile reading:of 60 tons per sq. in,

A CLUTCH PLATE THAT IS RESILIENT

THEplate carrying the facing material of a clutch is the better for being slightly resilient in compression, and patent No. 601,421 gives particulars of a plate of this nature. The patentee is the Borg and Beek Co., Ltd., Tachbrook Road, Leamington Spa.

A part of the proposed plate is shown; the sliding hub carries a disc portion (1), to which is riveted, as at 2, a number of separate cushion-plates (3). These are slightly bellied, as indicated by the shading (4), and the friction facings are placed one on each side. One facing is attached by the right-band set of rivets (5), whilst the facing on the other side is fixed by the left-hand set (6). This allows the resilience of the cushion plates to hold the friction rings slightly apart when free, but when subjected to the full spring pressure they can close up into a solid unit. The plates are gashed, as shown at 7, to give their tail-ends a measure of freedom.