ROAD MOTORS "HOT-UP CECREAM DISTRIBUTION

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

NOWADAYS, ice-cream may be classed as a universally distributed food, but few years have elapsed since it was regarded as little more than a delicacy, to be sampled on relatively few occasions in the summer and not at all during the remainder of the year. Even in the hottest weather, ice-cream was quite unobtainable a few years ago in many country places.

This change, of course, has not "just happened." There has for long been a vast potential market for icecream, but it was not until motor distribution was developed that the full value of modern bulk production could be realized. The scientific application of methods of production is necessary to ensure consistency of quality, but this preparation would fail in its object unless flexible and reliable transport were available to ensure that the ice-cream would reach the consumer in perfect condition.

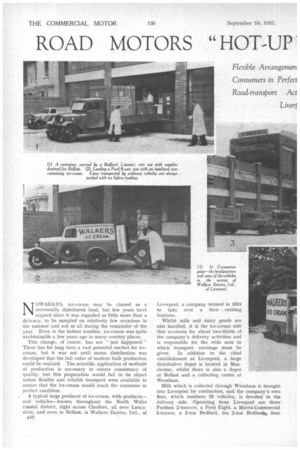

% A typical large producer of ice-cream, with products— and vehicles—known throughout the North Wales coastal district, right across Cheshire, all over Lancashire, and even in Belfast, is Walkers Dairies, Ltd., of 1312 Liverpool, a company formed in 1924 to take over a then existing business.

Whilst milk and dairy goods are also handled, it is the ice-cream side that accounts for about two-thirds of the company's delivery activities and is responsible for the wide area in which transport coverage must be given. In addition to the chief establishment at Liverpool, a large distributive depot is located in Manchester, whilst there is also a depot at Belfast and a collecting centre at Wrexham.

Milk which is collected through Wrexham is brought into Liverpool by contractors, and the company's own fleet, which numbers 29 vehicles, is devoted to the delivery side. Operating from Liverpool are three Fordson 2-tormers, a Ford Eight, a Morris-Commercial 3-tonner, a 3-ton Bedford, ten 2-ton Bedford, four 12-cwt. Bedfords with specially insulated van bodies, and the veteran of the fleet—a Chevrolet which started life in May, 1930. Belfast has an 8-cwt. Bedford, and at Manchester are stationed three 30-cwt. Chevrolets, three 2-ton Bedfords and a 12-cwt. I3edford with insulated body.

How the business has grown can be gauged from the fact that in 1924 a single model-T Ford van comprised the entire transport system. Now, in addition to selling ice-cream through shops and dairies, the company supplies chain stores throughout the uorth-west, also a large number of cinemas, and the ps esent fleet enables a firm guarantee of deliveries to be given at 24-hours (or less) frequency.

Not only has ice-cream to be delivered, but it must be accompanied by small supplies of dry ice which act as a cooling agent for the retailers' cold-storage boxes. The substance known as dry ice has had a considerable effect on transport for ice-cream. With ordinary ice, an amount almost equal to the weight of the load had to be carried so as to prevent the goods from deteriorating, but a few pounds of dry ice—perhaps, a twentieth or a thirtieth of the weight of the products— will now do all that is necessary.

Following tests with the four 12-cwt. Bedfords, Mr. G. Davies, the transport manager, looks upon insulated bodies as the coming type for the trade, since they obviate the use of cases and make possible the fullest use of the available space, whilst maintaining suitable conditions.

All other vehicles on ice-cream delivery carry goods in cases, which are insulated to ensure safe transit. Special bodywork for the vehicles is built by P. M. Willey and Sons, Ltd., of Liverpool. Cream colour is largely used in the finish of the vehicles, and a large-size representation of an angelic cherub invariably finds a place in the scheme of decoration.

Every attention is paid to maintaining a smart and 813 clean appearance a.nd the finish is " overhauled " every year, on the side of each machine being painted the date of the last repaint, or varnish, so that it is possible to check up the service given without reference to records.

Drivers are selected from types considered suitable for employment as driver-salesmen, because in contact with many of the customers they must necessarily be looked upon as the company's representatives. When on duty they wear neat, peaked dtiving caps and white coats which are provided by the company.

Although more ice-cream is now eaten in the winter than in the past. sales, naturally, drop during the cooler months, and in the past half a dozen machines have been off the road from October to January. However, there is no break in the continuity of employment for the men, for, in such circumstances, they are transferred to work inside.

The enthusiastic manner in which, during the past two or three years, numerous cinemas have developed ice-cream sales during performances is a factor in the extension of the "season," and, with increasing demands, it appears likely that the forthcoming winter will see machines stopped only for overhauls and because of the men's holidays, which must, 1 naturally, be taken . at slack periods.

Whilst there must not be delays in working, because of the need for keeping customers properly stocked, production by modern methods obviates the necessity of delivery work " rush " character.

Milk collected through Wrexham is bulked and brine chilled, then delivered to Liverpool, where the processes are carried out under laboratory conditions in extensive premises. Milk for sale is pasteurized, or sterilized, and bottled. Ice-cream ingredients, including milk and cream, are mixed, pasteurized and homogenized.

After cooling the mixture " ages " for six hours, is partially frozen and, finally, packed in boxes, cardboard tubs, cartons or tins, hardening in rooms where the temperature represents 72 degrees of frost—a degree of coldness that it was not possible to reach for this purpose until a few years ago. of a Made One Day, Delivered the Next.

Goods manufactured one day are ready for delivery the following day. Out of the cold store already mentioned is a connection to an ante-room, the temperature of which is kept at a slightly higher level, and from this room a door opens directly on to the loading deck. As they are transferred to the ante-room, prior to loading, the products are not exposed to sudden variations over a wide range of temperature.

With the insulated vans nothing more is needed than to place the various orders in the interior, together with some lumps of dry ice, but for the lorries and non-insulated vans packing in the insulated cases is required before loading takes place. Milk is loaded from a deck B I 4

which is situated at the opposite end of the building.

The first load for any day is actually dealt with the previous afternoon, this being the consignment for delivery in the Manchester area. After completing a short round, one of the Manchester depot Bedfords comes to Liverpool in the afternoon, collects a full load and returns to Manchester, where supplies are stored until the start of the following morning's work.

Containers for Sea Transit.

Later in the day a huge insulated lift-box, weighing about two tons when loaded, is packed and sent to the Belfast boat, upon which, by an arrangement with the shipping company, it is placed so as to receive priority treatment in unloading, being transferred, by the shipping company's delivery service, to the Belfast depot. A plain truck takes the lift-box to Liverpool Docks, this vehicle also being responsible for deliveries to liners (which take substantial amounts of ice-cream for consumption on their voyages) and for similar duties.

First off in the morning for Liverpool is a machine which starts at about 7 a.m, and delivers sterilized milk to restaurants and shops; other vehicles, on shop deliveries in the Liverpool district, follow later.

At 7.30 a.m. the first of the icecream motors is loaded and is due away, by 8 a.m. This proceeds on the North Wales round, which is the longest of all, with a returnjourney distance of

160 miles. After clearing the districts covered by the shorter rounds, calls start and about 80 deliveries must be made before the commencement of the homeward run, which is concluded about 7 p.m.

Lists of calls, based on knowledge of the normal possibilities of the run, are handed to the driver, but he is not tied to any particular schedule. On return to the office at night the calls sheet is checked over with the delivery notes, so that omissions could not be overlooked.

Journeys vary considerably in distance, the general rule being to arrange matters so that the longer the distance the fewer the number of calls. The shortest of the runs is about 50 miles, but the average is 100 miles, with approximately 60 calls.

With the fleet topping 500,000 miles per annum, Walkers Dairies Ltd., is a good customer of the petrol companies, and at the conclusion of the present year it will probably have used nearly 50,000 gallons for the period. A blend of hall straight spirit and half commercial mixture, a combination which is found to give good results, is used. Particularly satisfactory figures have been obtained from the Bedford 12-cwt. vehicles, which, despite fairly frequent stopping and starting, record a consumption equal to approximately 28 m.p.g.

With commodities that are both perishable and neces sitate a seven-day working Week chances cannot be taken on maintenance and, at Liverpool, three men are employed from about 4 p.m. until midnight each day on routine duties that include the nightly washing and

polishing of every vehicle. They also perform all adjustments required and correct any defect reported by the drivers. Satuiday and Sunday are the busiest days for the fleet, and, in preparation for the week-end, the garage staff has it own rush period on Fridays.

On returning to the garage on Friday, each driver submits to the transport office a report sheet which states the mechanical and general condition of his machine. Similar arrangements apply at Manchester and Belfast, but in those districts all maintenance is in the hands of outside motor engineers. One man at Liverpool is made specially responsible for attention to tyres.

Despite an average of over 60 stops and starts every day, good. mileages are secured from ordinary truck-type

covers, 30,000 miles being expected from those used on the 2-ton Bedfords. Covers removed from vehicles of this class operated on the North Wales run, where there are fewer stops, have reached 42,000 miles. Specimen figures for the rate of oil consumption with the same type of vehicle indicate an average approaching 2,000 m.p.g.

During the four months of the off-season the various units in the fleet are given a careful check-over, followed by a complete overhaul by commercial-vehicle specialists. Renewals are generally calculated on a six-year basis. Each year-end the state of the vehicles is reviewed, any new machines purchased being allocated to the longer journeys and the older units graded back to less-exacting work.