Lorry-body Feature that Improve Loading

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

THE number of platform lorries used by mineral-water manufacturers has increased by several hundreds during the past four or five years, owing to the development of house-to-house delivery service. These lorries usually have a single plain platform. The outer crates are kept in position by resting on the side or chock rails which project a couple of inches above the floor level.

The crates are piled on one another and as the top ones should be within reach of the vanman when standing on the ground, the load is seldom more than three crates high.

The mineral-water manufacturer, having established a good connection with an increasing number of customers, may extend the range of his products and the lorry will be called upon to carry several varieties of refreshment, any of which must be ready to hand so as to avoid delay when, possibly, more than a hundred calls have to be made in the course of a day.

Value of the Upper Deck, It is considered, therefore, that many of these harries will have some form of upper deck, or platform, to facilitate the arrangement and classification of the load_ Unless there be a step along the side of the body, the upper platform must be within convenient reach from the ground. To achieve this end there is a space between the main and upper platforms for only one layer of crates, whilst the upper platform is available_ for one or two layers of crates, as required.

The upper deck extends the full length of the loading portion, or it may be restricted to one-half or twothirds of this length so that space remains for piling the crates in the usual manner. This end space,. with full headroom, may be utilized for elO one or more lines that are chiefly in demand and during the course of the round the empty crates are placed at this point first.

The side rails of the platform should project sufficiently aboye the floor so that, when the vehicle is running on the camber of the road, the outer ends of the crates resting on the rails are not lower than the inner en Is. The crates may, of course, be carried inside the rail and lie flat on the floor, but this arrangement is practicable with only one layer of crates, because the upper crates will not have the safety inward slope.

As an alternative, projecting side rails are dispensed with and the floor itself slopes inwards the approximate length of a crate with a middle horizontal portion, or the floor slope extends from each side to the centre. With either arrangement, no time is lost in adjusting the crate to the siderail position ; furthermore, the whole of the bottom of the crate is in contact with the floor instead of along only two edges.

The drop sides of the larger type of lorry are much easier to handle now that it is the practice to divide a long side into two independently hinged portions, with centre and end stanchions. This facility may be still maintained even when the body is of maximum length, say, about 15 ft,

Keeping Weight Within Bounds.

In these instances, portions of the lorry side from 12 ins. to 15 ins, long are fixed at one or both ends. The weight of the drop side is then kept within reasonable limits, and the small fixed portions have little or no effect on the ease of access to the load.

Moreover, by limiting the size Of the opening the rigidity of the .body is hot unduly impaired. This point is also worth consideration when a drop side of extra length would be unwieldy, owing to its height being greater than usual.

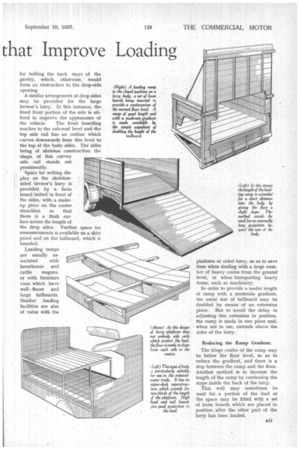

When the large drop-sided lorry has a front gantry, any fixed front portion of the side becomes available for bolting the back stays of the gantry, which, otherwise, would form an obstruction to the drop-side opening.

A similar arrangement of drop sides may be provided for the large brewer's lorry. In this instance, the fixed front portion of the side is utilized to improve the appearance of the vehicle. The front boarding reaches to the cab-roof level and the top side rail has an outline which curves downwards from this level to the top of the body sides. The sides being of skeleton construction the shape of this eurvey side rail stands out prominently.

Space for writing display on the skeletonsided brewer's lorry is provided by a facia board bolted in front of the sides, with a makeup piece on the centre stanchion so that there is a flush surface across the length of the drop sides. Further space for announcements is available on a skirt panel and on the tailboard, which is boarded.

Loading ramps are usually as sociated with horseboxes and cattle wagons, or with furniture vans which have well-floors and large tailboards. Similar loading facilities are also of value with the platform or sided lorry, so as to save time when dealing with a large number of heavy crates from the ground level, or when transporting heavy items, such as machinery.

In order to provide a useful length of ramp with a moderate gradient, the usual size of tailboard may be doubled by means of an extension piece. But to avoid the delay in adjusting this extension in position, the ramp is made in one piece and, when not in use, extends above the sides of the lorry.

Reducing the Ramp Gradient.

The hinge centre of the ramp may be below the floor level, so as to reduce the gradient, and there is a step between the ramp and the floor. Another method is to increase the length of the ramp by continuing the slope inside the back of the lorry.

This well may sometimes be used for a portion of the load or the space may be fitted with a set of loose boards which are placed in position after the other part of the lorry has been loaded.