Delivery pressures eased

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

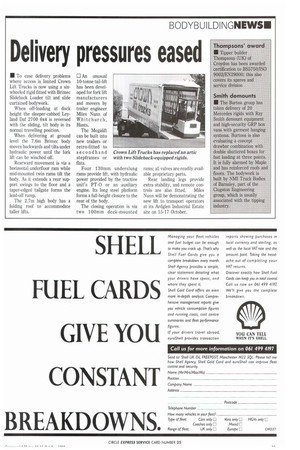

• To ease delivery problems where access is limited Crown Lift Trucks is now using a sixwheeled rigid fitted with Brimec Slideback Loader tilt and slide curtained bodywork.

When off-loading at dock height the sleeper-cabbed Leyland Dal 2700 63(4 is reversed with the sliding, tilt body in its normal travelling position.

When delivering at ground level the 7.6m Brimec body moves backwards and tilts under hydraulic power until the fork lift can be winched off.

Rearward movement is via a horizontal underfloor ram while mid-mounted twin rams tilt the body. As it extends a rear support swings to the floor and a taper-edged tailgate forms the lead-off ramp.

The 2.7m high body has a folding roof to accommodate taller lifts. An unusual 10-tonne tail-lift has been developed for fork lift manufacturers and movers by trailer engineer Miles Nunn of Whitchurch, Hants.

The Megalift can be built into new trailers or retro-fitted to secondhand stepframes or flats.

Four 130mm underslung rams provide lift, with hydraulic power provided by the tractive unit's PT-0 or an auxiliary engine. Its long steel platform forms a full-height closure to the rear of the body.

The closing operation is via two 100mm deck-mounted rams; all valves are readily available proprietary parts.

Rear landing legs provide extra stability, and remote con trols are also fitted. Miles Nunn will be demonstrating the new lift to transport operators at its Ardglen Industrial Estate site on 15-17 October.