No U-turns o n

Page 44

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

eight-legged Maggies

Tippermen Allinson Stone wanted a tough, no-nonsense vehicle and found it with the Magirus Deutz 8x4, as David Wilcox reports

J'RE looking for a Magirus in England you're most

to come across one ig on the course of a new -way under construction or loaded in a stone quarry. ause since Magirus Deutz stablished a proper base in nd in 1967, this German lecturer has enjoyed most ss in the UK market with its f road dump trucks and tip

sited Stockport-based tipperator Allinson Stone to ut what attracted this cornto Magirus Deutz — in its )f 35 eight-wheelers it runs Magirus Deutz 2320 30FK 3pers.

laging director Steve All in3Id me that the company een established 25 years Airely as a small tipper tor, but had then diversiIto selling the sand/stone was moving. From here it d into the actual quarrying if the business, and Allintone now owns a sandpit shire and a stone quarry in Derbyshire.

or customers are the large truction and civil engiIg companies for whom Ali supplies or moves all of stone, aggregate or for sizeable projects, such iotorway building. On a ler scale, Allinson also lies local builders with ials for house building and runs a number of Ford 0-Series four-wheelers for the smaller deliveries.

AEC Mammoth Majors had been, Allinson's choice for an eight-wheeler chassis until the early Seventies when the company went on to the leading eight-wheeler manufacturer, Fodens. Allinson's transport manager Peter Coverley explained that Foden had one large advantage in its favour — it was very close.

Sandbach in Cheshire is only about 20 miles away from Allinson at Stockport and what's more Allinson tippers run across to the Sandbach area often, and return with backloads of road salt for the local councils in the Greater Manchester area.

In those days, Allinson was allowed to deal direct with Fodens and pick up spares and parts from the factory while its vehicles were in the area. What could be simpler? To complete the local picture, Gardner engines (from Manchester), Edbro tipping gear (from Bolton) and Mackworth bodies (from Mackworth in Derbyshire) were all specified.

"It was ideal", said Peter. "We were near all the manufacturers and could get parts ourselves very quickly, which kept downtime to an absolute minimum."

Fodens however, fell from favour somewhat when the Foden S10 cab was introduced in Autumn 1978. Allinson Stone considered it a retrogressive step compared with the previous S80-Series cab Fodens had used on their eight-wheelers.

Steve Allinson explained: "The new 510 cab was too sophisticated, too good for us. As tipper operators we want a strong, straightforward cab with no frills. I think Fodens were trying to capture a bigger slice of the tractive unit market with the new cab, but this meant it was too up-market for us as tipper operators."

Allinson Stone gave the new S10-cabbed Fodens a fair chance and still runs them, but had already started looking around for alternatives. While keen on standardisation, Steve Allinson likes to run two types of eightwheeler chassis so that he hasn't got all his eggs in one basket.

"Having the fleet split between two manufacturers keeps both of them on their toes if they want to win a bigger order next year," added Steve wryly.

Searching for this second manufacturer in 1978, Allinson tried virtually all the eightwheelers on the market. Demonstrators from OAF, Volvo, Leyland and MAN all took their temporary place in the fleet.

Steve Allinson told me that he did not consider six-leggers: "it's like throwing money out of the window if you buy those," he said. "Their operating costs are only fractionally lower because you still pay the driver the same, but the payload is only 16 or 17 tons instead of 20."

Eventually Steve decided that the Magirus Deutz 232D 30FK eight-wheeler was the one for him. Why?

"It fitted the bill because it was strong and simple, as tippers should be. The chassis is solid; there's no doubt about that. But it was the cab that attracted us.

"You can put a hose in it and wash it out. It's light, but still made of steel so we can knock out any dents easily. And it's got plenty of ground clearance which is the most important thing for a tipper cab. The Maggies are better than the Fodens in this respect."

Of course, the Magirus had one other major factor in its favour — price. The 232D 30FIC had a list price around £3,00C less than the Foden and it alsc undercut (but rather more narrowly) most of the other eightwheelers on the market.

On top of this list price advantage, Steve admitted that Magirus were able to make him a very attractive offer — the company was working hard to establish itself in the eight-legger market, so Allinson as a medium/large tipper operator in an importani tipping area was a particularly worthwhile customer to win.

After running Fodens with Gardner 180s, a Magirus with its Deutz air-cooled engine was quite a departure for Allinson Stone. "It was a big decision" said Peter Coverley. "Our engineer already knew quite a lot about Deutz air cooled engines and he was confident in them, which helped enormously.

"We sent the fitters on courses to Magirus Deutz at Winsford, so everyone approached the new Maggies in the right frame of mind. That's half the battle if you're trying to get something new accepted."

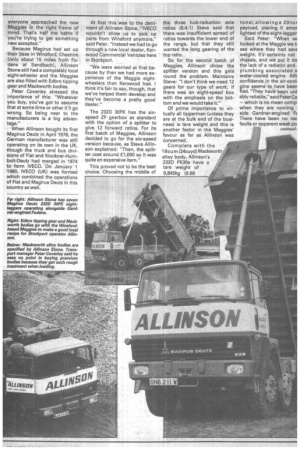

Because Magirus had set up their base in Winsford, Cheshire (only about 15 miles from Fodens at Sandbach), Allinson Stone still had a completely local eight-wheeler and the Maggies are also fitted with Edbro tipping gear and Mackworth bodies.

Peter Coverley stressed the importance of this: "Whatever you buy, you've got to assume that at some time or other it'll go wrong. So being near to the manufacturers is a big advantage."

When Allinson bought its first Magirus Deutz in April 1978, the German manufacturer was still operating on its own in the UK, though the truck and bus divisions of Fiat and Klockner-Humbolt-Deutz had merged in 1974 to form IVECO. On January 1 1980, IVECO (UK) was formed which combined the operations of Fiat and Magirus Deutz in this country as well. At first this was to the detriment of Allinson Stone. "IVECO wouldn't allow us to pick up parts from Winsford anymore," said Peter. "Instead we had to go through a new local dealer, Kenwood Commercial Vehicles here in Stockport.

"We were worried at first because by then we had more experience of the Maggie eightwheelers than Kenwood had. I think it's fair to say, though, that we've helped them develop and they've become a pretty good dealer."

The 232D 30FK has the sixspeed ZF gearbox as standard with the option of a splitter to give 12 forward ratios. For its first batch of Maggies, Allinson decided to go for the six-speed version because, as Steve Allinson explained: "Then, the splitter cost around £1,000 so it was quite an expensive item."

This proved not to be the best choice. Choosing the middle of the three hub-reduction axle ratios (6.4:1) Steve said that there was insufficient spread of ratios towards the lower end of the range, but that they still wanted the long gearing of the top ratio.

So for the second batch of Maggies, Allinson chose the splitter version and this gets round the problem. Maintains Steve: "I don't think we need 12 gears for our type of work; if there was an eight-speed box with the emphasis on the bottom end we would take it."

Of prime importance to virtually all tippermen (unless they are at the bulk end of the business) is tare weight and this is another factor in the Maggies' favour as far as Allinson was concerned.

Complete with the 18 c u m (24cuyd) Mackworth alloy body, Allinson's 232D FK3Os have a tare weight of 9,845kg (9.69 tons),allowing a 20-tor payload, placing it amor lightest of the eight-legger Said Peter: "When vv( looked at the Maggie we ti see where they had savE weight. It's certainly not chassis, and we put it do the lack of a radiator and plumbing associated v water-cooled engine. Allii confidence in the air-coolt gine seems to have been fled. "They have been unt ably reliable," said Peter Co — which is no mean compi when they are running side Gardner-engined Fc There have been no rec faults or apparent weak po Deutz V8 engine develops (228bhp) at 2,650rpm is roughly the class averor a 30-tonner. I asked if he felt this was about think anything over 200 power is adequate, though irivers will tell you wise," he replied. "We've lObhp Gardner-engined Foalongside a Rolls 265-enversion and the only perto really benefits from the power is the man who runs a-bar.

e driver with the Rolls enhas an extra cup of tea he waits for the Gardner to get there."

! same question asked of )f Allinson Stone's drivers iced a different response. rould have liked a more rful engine. "You're always ling gear with these Mag' he said which is more a tion of their relatively low e figure of 722Nm (530 Ibfit) 30-1,600rpm.

ig minus against the Megight-wheeler must be its consumption. Allinson's ge around 47 lit/100km g) which is not particularly )ssive, even taking into acthe hilly terrain of the Peak ct in which they often ate. In comparison, the ler-engined Fodens aver).2 lit/100km (7.2mpg).

Stave Allinson agreed that the Magirus Deutz consumption figure is not particularly satisfactory, but reasoned that because the Maggies had been so reliable, the reduction in downtime more than compensated for the higher fuel consumption.

Allinson carries out its own maintenance on the tippers, based around a weekly inspection system. With no watercooling circuit, the 232D 30FKs therefore have one whole area of maintenance removed and Peter Coverley said the rest was straightforward.

He specially mentioned that the centrifugal oil filter was worthy of careful attention it should be cleaned regularly and frequently.

Although the Magirus cab has a relatively shallow tilt (just 241, Peter said that engine accessibility was perfectly acceptable. Steve Allinson commented spare parts are more expensive, but that the old argument holds true you need less of them.

Points singled out for praise by Steve and Peter were the Maggies' good brakes (they have a very respectable frictional area of 11,464sqcm) which are appreciated in the Peak District, and the quick warm-up of the air-cooled engine. On a cold winter's morning there's warmth coming into the cab within the first mile or so.

Peter also noted that the electrics on the Maggies are particularly neat "very tidy with good, waterproof junction boxes". An important point for a tipper operating on a wet, muddy site. He also said that the Magirus has good off-road performance, and that the plentiful ground clearance of the cab was invaluable; only the bottom step is prone to getting caught.

The mounting of the headlights in the Magirus Deutz bumper was not liked by Peter Coverley; it's all too easy to put the lights out of alignment if you catch the bumper on anything. He appreciated that the maximum height restriction for headlamps (the top of the lamp must be no higher than 1,200mm) dictated their position, but felt that they should be mounted independently within the bumper rather than being part of it.

From the driver's point of view, Magirus has responded to the main criticism and included a suspension seat in the last year or so.

Apart from this, Magirus Deutz has kept the cab functional which is just what Steve Allinson as a tipperman wants. Visibility is good with a wrap-round onepiece screen, rear three-quarter windows and a kerb window set in the nearside door.

A couple of the windscreens have shown a tendency to crack in one corner of Allinson's Maggies, but Peter Coverley did not put too much significance on this.

The Magirus cab is now one of the oldest still in use, and it has long been replaced with the newer version on the IVECO tractive units. Despite its age, the cab does not look too dated to most people and Allinson Stone positively likes it that way. "It looks the part, doesn't it?' said Steve Allinson and sinc( Magirus Deutz moved the badgE from the front panel to the grill i leaves a good space for th( operator's name.

Despite introducing a new cat for the tractive units some year ago, IVECO says it has no plan: to rationalise and replace the oft cab on the eight-or six-wheelers which should keep Steve Allin son happy.

Allinson tippers tend tc operate mainly within a 25-mil( radius of Stockport and aver ages around 60,000 miles a year The company usually keep( them for about five years befor( selling them, and they are mos commonly bought by owner drivers or smaller companies ir the "muck-shiftingor demoli tion end of the tipper business.

This question of second-hanc residual value is the one area ir which the Magirus Deutz eight leggers are still an unknowr quantity for Allinson Stone. Th( company's first batch were soft back to Magirus Deutz withir three years as a very attractiv( part exchange for the new ones which are W-registered.

Steve Allinson pointed ou that many owner-drivers prefe to buy well-established vehicles partly because of the plentifu supply of spares at breakers This deters them from buyinc Maggie eight-or six-wheelers a the moment because they hav( to buy all the parts across th( counter at full-price.

When the occasional Magirul Deutz does appear in a breaker! yard, it's hot property.

Steve said that he knew othe tipper operators and owner-driv ers in the area were watching t( see how Allinson Stone fare( with its Maggies. The major hur dle that most of them struggle t( clear is to have 100 per cent con fidence in an air-cooled engine Allinson Stone seems to have a least cleared this hurdle with single bound.