Four-car Transporter on Rigid Chassis

Page 54

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

nESIGNED, developed and manufac

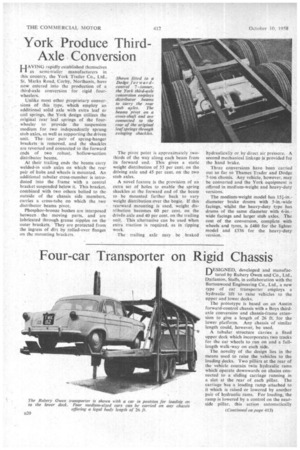

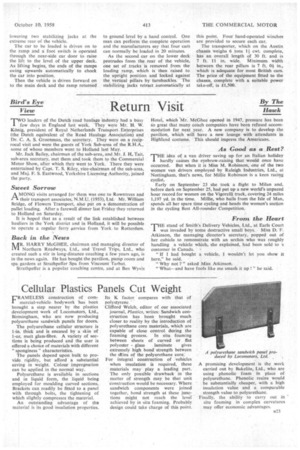

tured by Rubery Owen and Co., Ltd., Darlaston, Staffs, in collaboration with the Burtonwood Engineering Co., Ltd., a new type of car transporter employs a hydraulic lift to raise vehicles to the upper and lower decks.

The prototype is based on an Austin forward-control chassis with a Boys thirdaxle conversion and chassis-frame extension to give a length of 26 ft. for the lower platform. Any chassis of similar length could, however, be used.

A tubular structure carries a fixed upper deck which incorporates two tracks for the car wheels to run on and a fulllength walk-way on each side.

The novelty of the design lies in the means used to raise the vehicles to the loading decks. Two pillars at the rear of the vehicle contain twin hydraulic rams which operate downwards on chains connected to a sliding carriage running in a slot at the rear of each pillar. The carriage has a loading ramp attached to it which is raised or lowered by another pair of hydraulic rams. For loading, the ramp is lowered by a control on the nearside pillar, this action automatically lowering two stabilizing jacks at the extreme rear of the vehicle.

The car to be loaded is driven on to the ramp and a foot switch is operated through the near-side car door to raise the lift to the level of the upper deck. As lifting begins, the ends of the ramps swing upwards automatically to chock the car into position.

Then the vehicle is driven forward on to the main deck and the ramp returned to ground level by a hand control. One man can perform the complete operation and the manufacturers say that four cars can normally be loaded in 20 minutes. As the second car on the lower deck protrudes from the rear of the vehicle, one set of tracks is removed from the loading ramp, which is then raised to the, upright position and locked against the vertical pillars by turnbuckles. The stabilizing .jacks retract automatically at this point. Four hand-operated winches are provided to secure each car. The transporter, which on the Austin chassis weighs 6 tons 11 cwt. complete, has an overall length of 30 ft. and is 7 ft. 11 in. wide. Minimum width between the rear pillars is 7 ft. 04 in„ which' is adequate for most British cars. The price of the equipment fitted to the chassis, complete with a suitable power take-off, is £1,500.